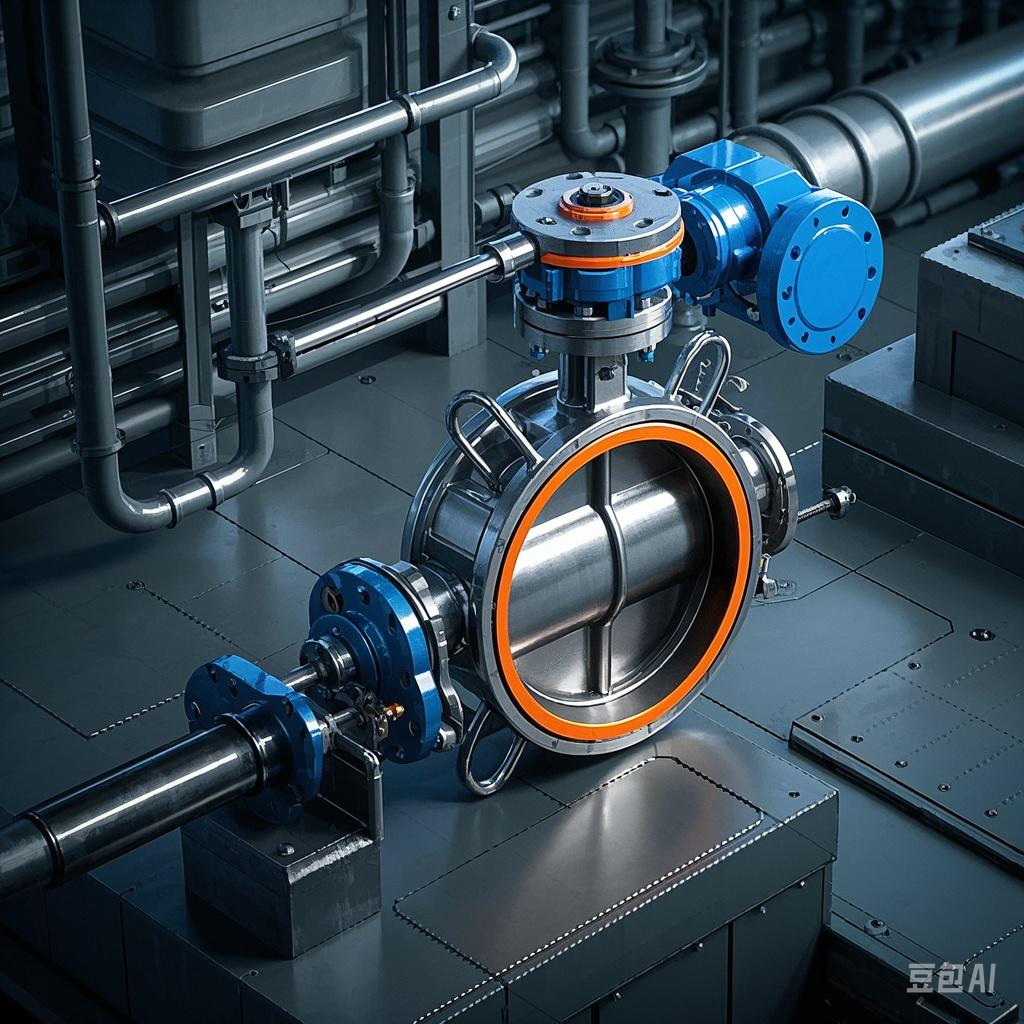

Butterfly Valve: The Flexible Butterfly Switch in Pipelines

In complex piping networks, there is one type of valve that attracts attention for its unique design and wide range of applications: the butterfly valve. Imagine a circular butterfly plate gently rotating like a butterfly’s wings in a pipeline, controlling the flow of fluid. Today, let’s explore this “butterfly” switch in the pipeline – the butterfly valve.

Working Principle of Butterfly Valve

The core component of the butterfly valve is a disk-shaped butterfly plate, which is installed in the direction of the diameter of the pipeline. When the butterfly plate rotates around its axis, it is like a butterfly dancing, and the rotation angle changes from 0° to 90°. When the butterfly plate is rotated to 90°, the valve is in the fully open state, and the fluid can flow through unhindered. By adjusting the rotation angle of the butterfly plate, we can easily regulate and cut off the fluid in the pipeline.

Wide application of butterfly valve

Butterfly valve is favored for its simple structure, easy operation and good sealing performance. It is widely used in various engineering systems, such as furnace, gas, natural gas, liquefied petroleum gas, city gas, hot and cold air treatment, chemical smelting and power generation and environmental protection. In these systems, butterfly valves are used to convey a variety of corrosive or non-corrosive fluid media, by regulating and truncating the flow of media to meet the process requirements.

Unique advantages of butterfly valve

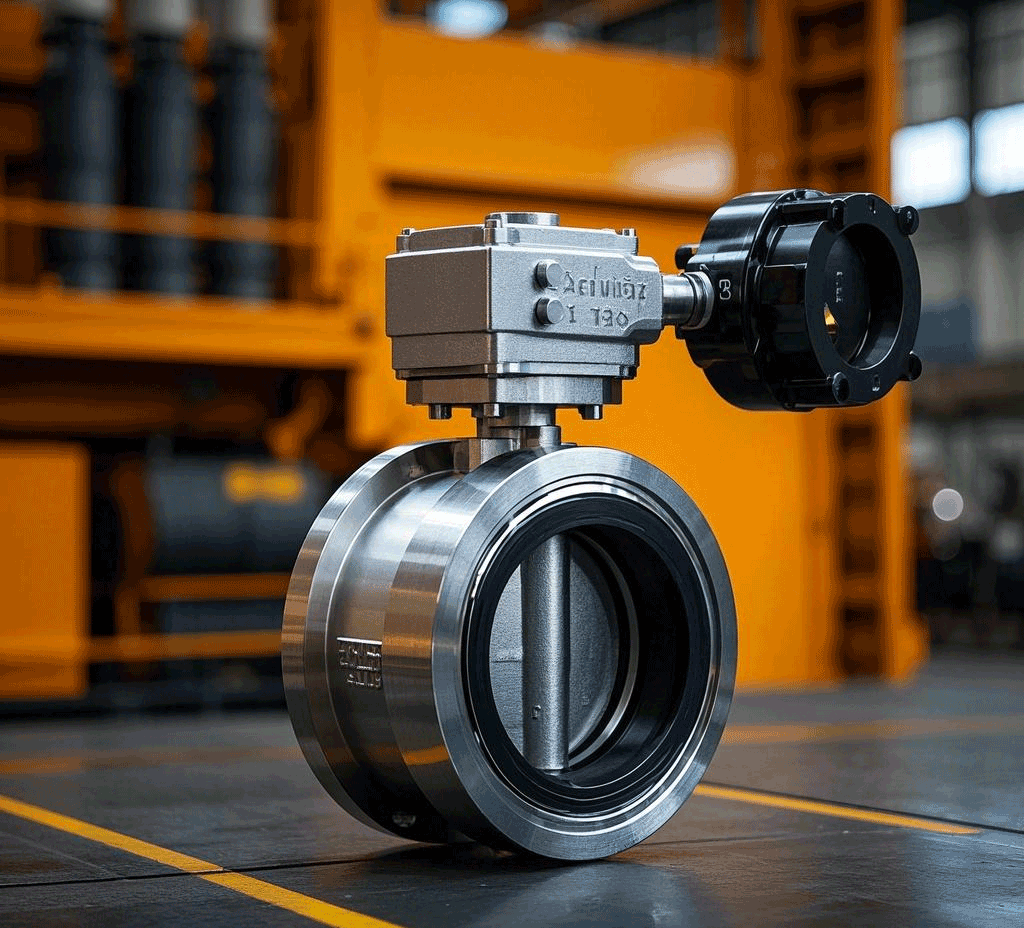

Butterfly valve can stand out among many valves thanks to its unique advantages. First of all, its structure is very compact and occupies little space, which makes it more suitable in occasions with compact pipeline layout. Secondly, the butterfly valve is very easy to operate, only a slight twist can realize the opening, closing and adjusting functions. In addition, butterfly valves also have good sealing performance, even under high pressure or high temperature environment can maintain stable sealing effect.

Versatility and Customization of Butterfly Valves

In order to meet the needs of different application scenarios, butterfly valves also provide a variety of materials and specifications to choose from. From common metal materials to special corrosion-resistant alloy materials, butterfly valves can be customized according to specific needs. At the same time, butterfly valves can also be custom-designed according to the size and pressure level of the pipeline to ensure optimal suitability and performance.

Overall, the butterfly valve has become a star product in piping systems with its unique design and wide range of applications. It is not only able to flexibly regulate and cut off fluid flow, but also has the advantages of simple structure, easy operation and good sealing performance. For users who need efficient, reliable and flexible piping control system, butterfly valve is undoubtedly an ideal choice.