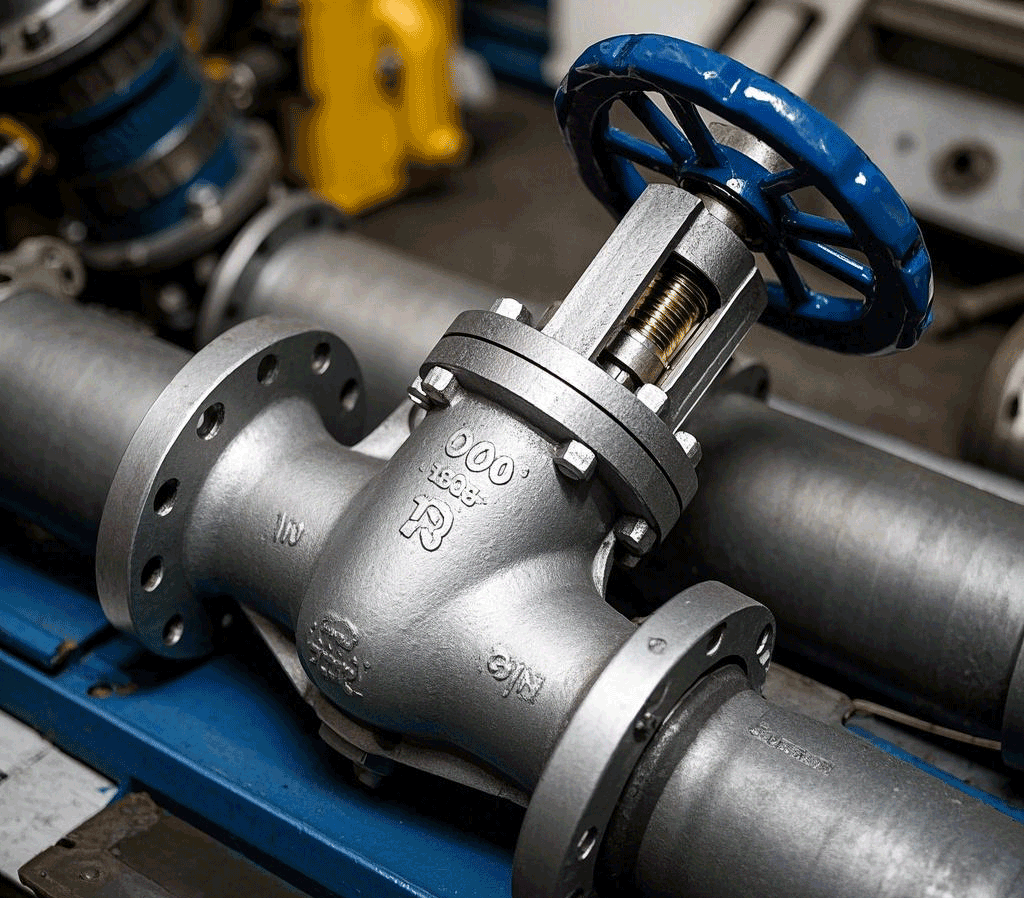

Gate valve, the key component of its opening and closing is the gate. The direction of movement of the gate is perpendicular to the direction of fluid flow. This means that gate valves are mainly used to completely open or completely close fluid passages without the function of regulating or throttling.

Forged steel gate valves are particularly suitable for use in small-diameter piping systems with an operating pressure range of Class150 to 2500 and an operating temperature of -29°C to 425°C (for carbon steel) or -29°C to 500°C (for stainless steel). Their main function is to cut off or connect the fluid medium in the pipeline. By choosing different materials, forged steel gate valves can be widely used in a variety of media, such as water, steam, oil, nitric acid, acetic acid, oxidizing media and urea.

The gate is designed with two sealing surfaces, of which the most common is the wedge sealing surface. The size of the wedge angle varies according to the specific parameters of the valve, with a common angle of 50°, while at lower media temperatures the angle may be adjusted to 2°52′. Depending on the design, there are two types of gate plates for wedge gate valves: one is monolithic and is also known as a rigid gate; the other is a gate that is capable of producing a slight deformation, which is designed to improve workmanship and compensate for possible deviations in the angle of the sealing surfaces during machining, and which is known as a resilient gate.

Overall, gate valves, with their simple but effective design, play an important role in piping systems that require complete disconnection or connection of a fluid medium.