Valves play a vital role in the industrial and aerospace sectors. Two common types of valves are needle valves and globe valves, and while they are similar in some ways, each has unique characteristics and uses. Below, we will provide you with a detailed description of the differences between these two types of valves.

I. Definition and designation

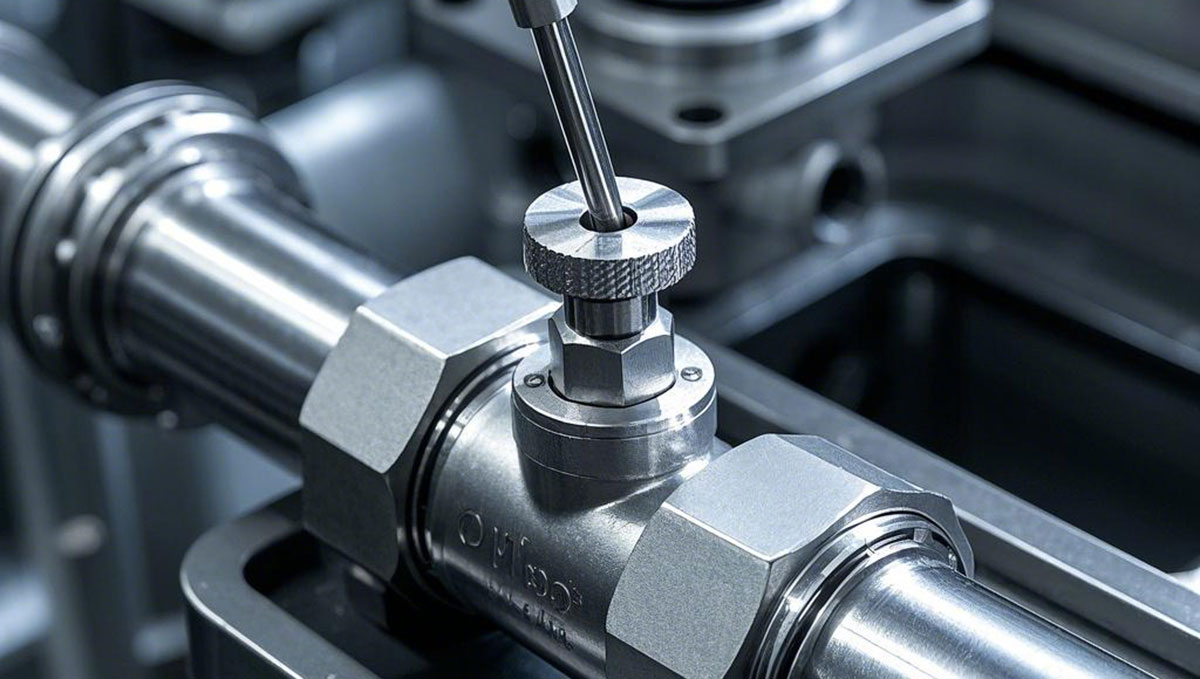

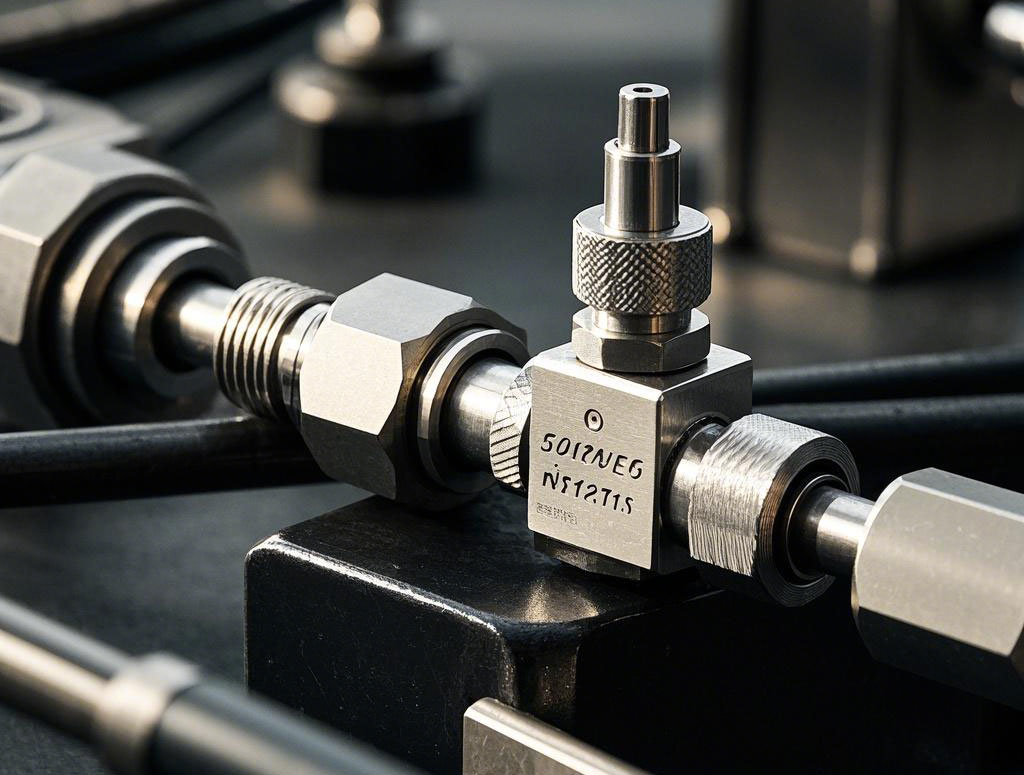

- Needle Valve: Needle valve is a type of valve that can be precisely adjusted, and it actually belongs to a special type of globe valve. Its name comes from its unique spool design, the shape of a sharp needle, can be precisely inserted into the valve seat. 2. Globe Valve: A globe valve, also known as a shut-off valve, is a forced-seal type of valve. When the valve is closed, pressure needs to be applied to the valve flap to ensure that the sealing surface fits tightly, thus preventing the flow of media. In our valve standardization, the flow direction of the shut-off valve is specified as top-down, so you need to pay attention to the direction of the installation.

Second, the principle of operation - Needle valve: the working principle of needle valve is to adjust the position of the spool (a sharp cone) in the valve seat to achieve precise control of fluid flow. This design allows needle valves to excel in applications where high precision flow control is required.

- Globe Valves: Globe valves work by relying on the pressure of the valve lever to make the sealing surface of the valve flap and the valve seat sealing surface close to each other, thus preventing the flow of media. This forced sealing method makes the globe valve in the need for high sealing performance is very suitable for the occasion.

Third, the use and application - needle valve: needle valve is usually used for smaller flow, higher pressure gas or liquid media sealing. Due to its precise control ability, needle valve is often used in conjunction with a pressure gauge to ensure stable operation of the system.

- Globe Valve: As one of the most important cut-off type valves, globe valve plays a vital role in aerospace field. It can not only realize the functions of medium conveying, stopping and regulating, but its sealing performance also directly affects the safe and reliable operation of aerospace equipment. Therefore, in aerospace equipment, globe valve is an indispensable and important component. In summary, although needle valve and globe valve are both a kind of valve, but they are in the definition, working principle and use there are obvious differences. Understanding these differences will help you make more informed decisions when selecting and using valves.