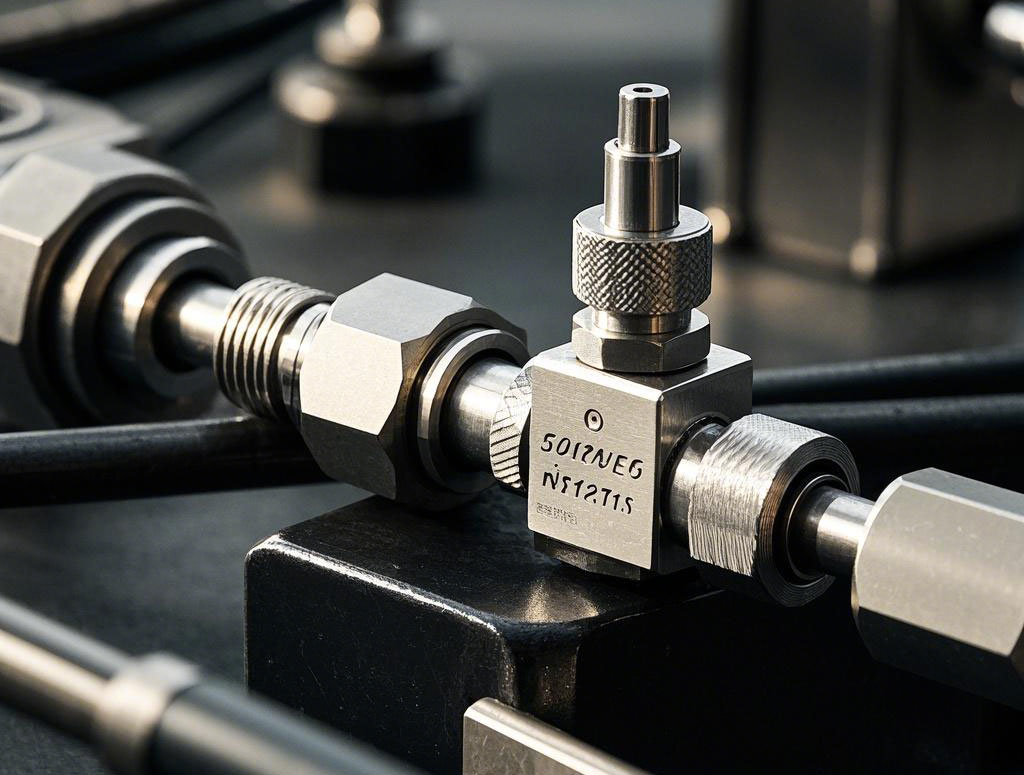

Needle valve, this precision tool in the field of fluid control, its main function is to regulate the flow of liquid or gas. It controls the degree of opening of the fluid passage through the fine movement of the needle valve stem, thus realizing the precise regulation of flow.

Imagine a needle valve as a “fine tuner” for flow control. It consists of several key parts: the valve body, valve stem, valve seat and seals. As the valve stem moves slowly downward, its needle-like end becomes tightly embedded in the hole in the valve seat, like a finger gently pinching the opening of a water pipe, making the flow of water slow and small. In this way, the amount of fluid passing through the valve is reduced, achieving the purpose of regulating flow. Conversely, if the stem is moved upward, the stem tip is withdrawn from the valve seat, the fluid passage becomes more spacious, and the flow rate is increased.

The ingenious design of the needle valve is that it is capable of very precise adjustment over a very small flow range. This is difficult to match with other types of valves. As a result, needle valves have become indispensable in the chemical industry, aerospace, instrumentation, and other areas where careful control of flow is required.

In addition to this, needle valves have good sealing performance. Its seals are precisely designed to effectively prevent fluid leakage. This feature makes needle valves widely used in applications that require high sealing performance.

What are the operating principles of needle valves