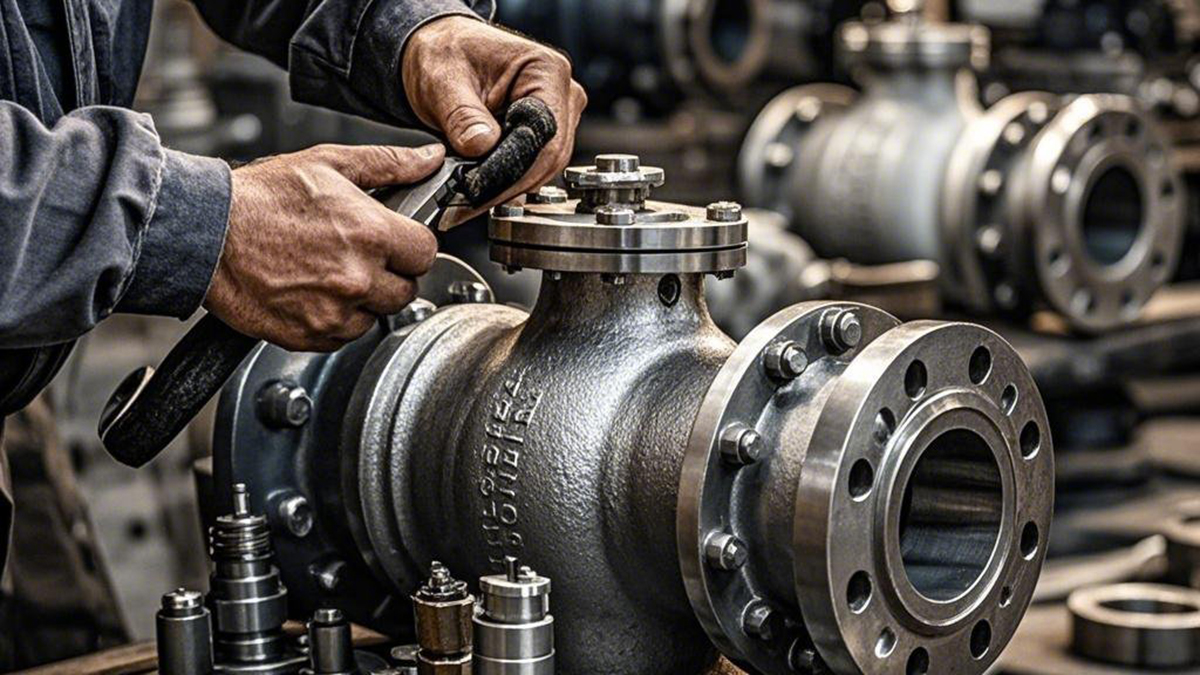

Valve material selection directly affects the equipment life and system safety. This article compares the characteristics of mainstream materials to help you make scientific decisions based on the needs of the working conditions.

First, the metal valve material

- carbon steel (Carbon Steel)

Features: high strength, moderate corrosion resistance, low cost.

Application: water, steam, oil (≤ 425 ℃), general chemical media.

Standard: ASTM A105 (forged steel), ASTM A216 WCB (cast steel). - Stainless steel (Stainless Steel)

Advantages: Corrosion resistance (e.g. 316L Cl- resistant), high temperature resistance (≤650℃), sanitary design.

Typical scenarios: food processing, pharmaceutical, chemical reactor.

Common grades: 304 (general purpose), 316L (acid-resistant), 904L (high concentration of sulfuric acid). - Cast iron (Cast Iron)

Characteristics: good wear resistance, low price.

Limitations: high brittleness, not suitable for high pressure (≤ 1.6MPa) or low temperature (≥ -10 ℃).

Application: municipal water supply, sewage system. - Copper Alloys (Copper Alloys)

Performance: excellent corrosion resistance (such as brass resistance to fresh water), easy processing.

Scenario: air conditioning refrigerant, drinking water piping (lead-free brass in line with NSF standards).

Second, non-metallic valve materials

Material Type Core Advantages Typical Applications Temperature Range

Plastic Lightweight, corrosion-resistant Chemical (PP/PE), Irrigation (PVC) -40°C ~ 100°C

Rubber Highly elastic, low cost Water valve seals, diaphragm valves -20°C ~ 80°C

Ceramics Super wear-resistant (HRC70+), resistant to strong acids and alkalis Mineral slurry, concentrated sulfuric acid transportation -200℃ ~ 1500℃

Fluorine plastic (PTFE) extreme corrosion resistance (aqua regia), low friction semiconductor etching, pharmaceutical intermediates -196 ℃ ~ 260 ℃

Third, the key principles of selection

Medium Characteristics

Corrosive → stainless steel / fluorine plastic.

Containing particles → ceramic / carbide.

Working conditions

High temperature and pressure → chrome molybdenum steel (such as A182 F22).

Low temperature → Austenitic stainless steel (304L / -196°C).

Cost balance

Economical → cast iron / plastic.

Long life → ceramic / nickel-based alloy.

IV. Industry Application Cases

Petroleum refining

Ball valve: carbon steel (body) + carbide (sealing surface).

Control valve: 316L stainless steel (H₂S resistant).

New Energy

Hydrogen energy valve: titanium alloy (anti-hydrogen embrittlement).

Photovoltaic cleaning: PVDF diaphragm valve.

Food & Pharmaceutical

Butterfly valve: 316L polished (Ra≤0.8μm).

Diaphragm valve: Silicone seal (FDA approved).

V. Maintenance and Upgrade Recommendations

Corrosion monitoring

Regular ultrasonic thickness measurement (thinning >30% needs to be replaced).

Electrochemical noise detection (EN 12952-16 standard).

Material Upgrade

Carbon steel valves → ceramic coating (life expectancy increased by 2 times).

Rubber sealing → perfluoroether (temperature resistance + 50°C).

Summary

The choice of valve material should be based on the medium, temperature, pressure and other factors. It is recommended to contact the ISO 9001/API 600 certified suppliers to obtain professional material suitability analysis. Correct selection of materials can reduce maintenance costs by more than 40%, to ensure long-term stable operation of the system.