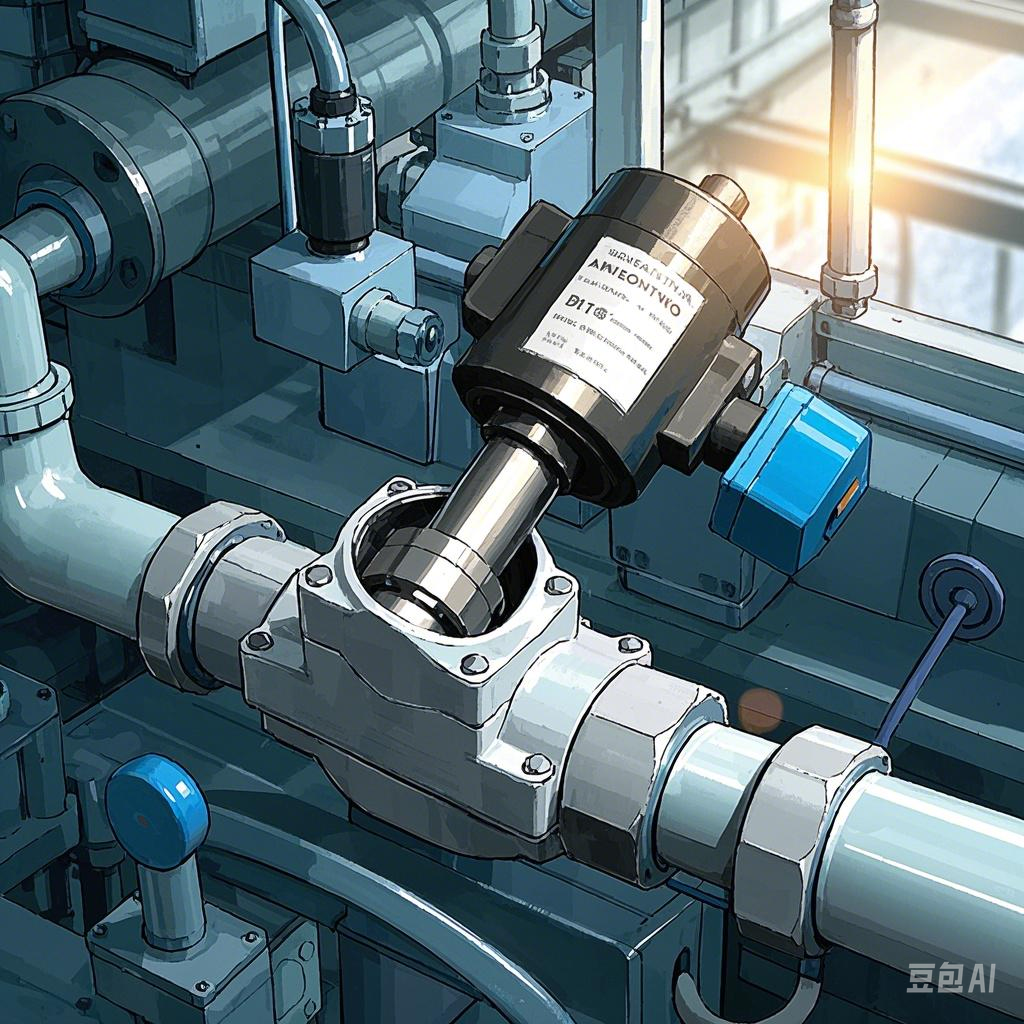

The Angle Seat Valve is an ingeniously designed, powerful fluid control device that helps save valuable space by maintaining a steady flow. This valve features a guided design driven by a single-acting pneumatic actuator and is equipped with bearing safety guards to ensure stable and safe operation. When choosing to use it, you can select either a normally open or normally closed type as required.

Particularly suitable for applications requiring rapid opening for short periods of time, the angle seat valve stands out for its rapid response and precise action. Combined with solenoid valves, it can realize precise adjustment of gas and liquid flow through hydraulic control, which meets the high demand for precise temperature control and drip control of angle seat valves.

Widely used in daily life:

Angle valve seat valve can control various gases, including neutral gases and air, to ensure indoor air quality.

It is also suitable for controlling various liquids, such as automatic industrial control fluids, food-grade dairy products, domestic water, and fluid media in general pipelines, to ensure the safe use of domestic and industrial fluids.

Remarkable features of angle seat valve:

The valve is equipped with an indicator, which can clearly show the open or closed status of the valve.

The internal pneumatic pilot design not only prolongs the service life, but also reduces the need for maintenance.

Self-adjusting sealing gland is equipped between the relief port and the slider, which effectively improves the sealing performance.

The unique design of the angle seat structure allows the valve to handle large flow rates (especially compared to general globe valves) in a compact and responsive manner.

According to the function of spring return opening and closing, angle seat valves can be categorized into normally open and normally closed types. Single-acting and double-acting cylinders are utilized to achieve valve opening and closing.

Double-acting (pneumatic head usually has two holes): the working principle is to realize the opening and truncation switch of the valve by controlling the air supply.

Single-acting (pneumatic head usually has one hole): the working principle is to open the valve when air supply, and close it by spring return when air supply is interrupted.

Angle seat valves are made of stainless steel and PTFE materials and are suitable for the control of most gases and liquids. For steam and corrosive environments, it is also equipped with a heat sink to protect the actuator.

To ensure that the angle seat valve has a long service life and a flexible mounting position, the actuator housing can be rotated 350 degrees for easy positioning of the pressure connection. The valve is also equipped with a standard indicator for open or closed status, allowing you to see the current status of the valve at a glance.

When installing and servicing angle seat valves, be sure to observe the following safety regulations:

Ensure that the piping is clean and free of contamination to ensure proper operation of the valve.

Install according to actual needs, but try to avoid having the actuator face up and pay attention to the direction of fluid flow.

When connecting the valve, make sure the piping is aligned. Do not disassemble the actuator unless specifically requested by the user.

Angle seat valves have become indispensable fluid control devices in many fields because of their efficient space utilization and precise flow control capability.