In modern industrial production, valves are extremely important for fluid control and to ensure the safe operation of equipment. It has a wide range of applications and a wide variety of common ones are as follows:

Gate valve

The opening and closing parts of the gate valve is the gate, the gate movement direction and the direction of the fluid perpendicular. Gate valve can only be fully open or fully closed, there is no way to adjust the flow or throttling. It has a simple structure, low resistance when the fluid flows through, unrestricted fluid flow direction, and is durable. Can be used to control water, steam, oil, corrosive media and other fluids.

Globe Valve

Globe valve relies on the valve stem to exert pressure, so that the valve sealing surface and the valve seat sealing surface tightly affixed to prevent the passage of fluid. It is suitable for cutting off the fluid path, but also can regulate the flow. Globe valve has a simple structure, easy to manufacture and maintain, good sealing performance and long service life. However, it requires a large torque to open and close, which is laborious to operate, and there are restrictions on the direction of fluid flow. When installing the globe valve, pay attention to the water or steam flow direction, usually “low into the high out”, that is, the fluid from the lower part of the spool into the spool, and then from the spool and the valve seat of the middle of the flow, so as to ensure that the valve works properly and has good sealing performance.

Plug Valves

The plug of the plug valve is generally cylindrical or conical, and the shape of the channel can be rectangular or trapezoidal. It has a simple structure, few parts, fast switching speed, suitable for places that need to quickly cut off or connect the fluid. The sealing surface of the plug valve is precision machined to fit tightly and have good sealing performance. Especially soft seal plug valves are often used for corrosive, highly toxic and high hazardous media and other harsh environments, which have strict requirements for leakage. Plug valve installation direction is not restricted, the fluid flow direction can be chosen at will, which makes the pipeline layout more flexible. However, plug valves also have disadvantages, such as not suitable for high temperature and high pressure media, and in some cases there may be clogging problems.

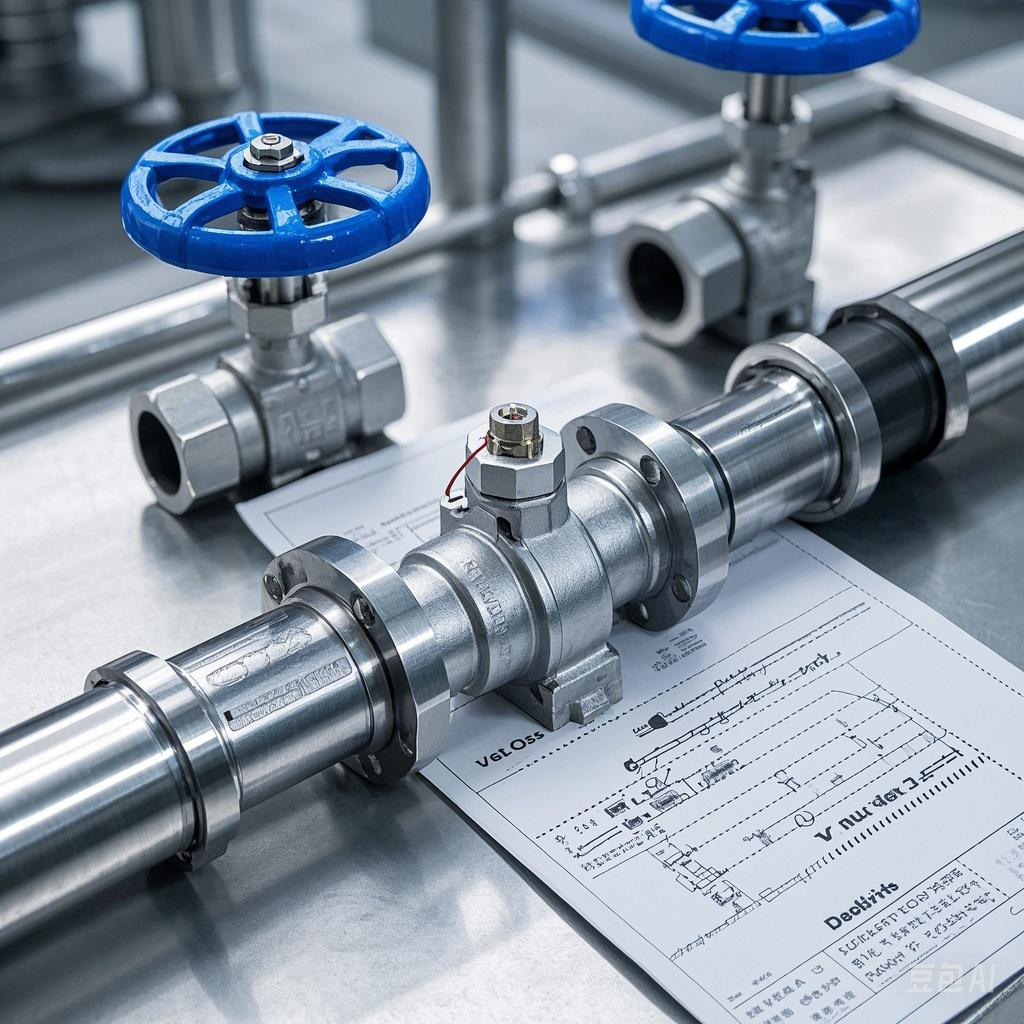

Ball Valves

The opening and closing parts of the ball valve is a sphere with a hole, the sphere rotates around the axis perpendicular to the channel to realize the opening and closing of the channel. The ball valve has the least resistance to fluid of all valves and is suitable for shutting off or isolating systems. It is quick and easy to switch, the valve stem rotates 90 degrees, the ball valve can complete the full open or full closed action, so in the need for frequent switching occasions obvious advantages. Ball valve sealing performance is good, long service life, installation is also simple, can be installed in any direction in any position of the pipeline, installation is very flexible. Can also be configured with pneumatic, electric, hydraulic and other drive mechanisms to achieve remote control and automated operation, which makes the ball valve application range is wider. Because of these features, ball valves are widely used in the pipeline control system of petrochemical, chemical, electric power, water treatment, paper making and other industries.

Butterfly Valve

Butterfly valve, also called flap valve or butterfly valve, is a simple structure of the regulating valve, by adjusting the position of the butterfly to control the fluid flow. When the butterfly rotates, the fluid passes through the butterfly and the flow rate changes. Butterfly valve is mainly composed of valve body, valve stem, butterfly plate and other components. It has simple structure, small volume, light weight, less material consumption, small installation size, occupies little space in the piping system, and is easy to install and maintain. Butterfly valve operating torque is small, fast switching speed, rotating 90 ° can complete the opening and closing action. It has a wide range of applications, can be used in low-pressure pipelines, can also be used in the medium is mud and other impurities in the pipeline, in the pipeline mouth is not easy to accumulate impurities, suitable for a variety of working conditions, so in the pipeline system has been widely used and recognized.

Diaphragm Valves

Diaphragm valves utilize a diaphragm to control the passage of fluid. Its structure is relatively simple, mainly composed of valve body, diaphragm, valve cover, valve stem and other parts. Diaphragm is the core component of the diaphragm valve, made of rubber, PTFE plastic and other soft materials, used to close the flow path, cut off the fluid, but also the valve body cavity and the valve cover cavity. Due to the limitations of the diaphragm material, diaphragm valves are generally suitable for low pressure and low temperature environment. Diaphragm valve body commonly used plastic, fiberglass, ceramic or metal lining materials to adapt to the corrosive requirements of different media. Diaphragm valve operation will not produce sparks or static electricity and other dangerous factors, suitable for flammable and explosive and other hazardous occasions, can guarantee the safe operation of pipeline systems. Diaphragm valves have unique advantages in conveying corrosive and viscous fluids, and are widely used in many industries such as chemical, petroleum, pharmaceutical, food and so on.

Check Valve

Check valves, also known as check valves or backstop valves, are used to prevent the backflow of media in the pipeline. The bottom valve of water pump suction port also belongs to check valve. Check valve is mainly composed of valve body, valve flap, spring. Valve is the key component to control the unidirectional flow of fluid. When the fluid flows in one direction to the check valve, the valve flap immediately open, so that the fluid through the pipeline normally; when the fluid direction is opposite, the reverse pressure will make the valve flap closed to stop the fluid backflow. Check valves are widely used in piping systems for liquids, gases and steam, etc. They can effectively prevent backflow of media, avoid pipeline bursts and other accidents, and safeguard the safety of equipment and personnel.

An

Types of valves and their application scenarios