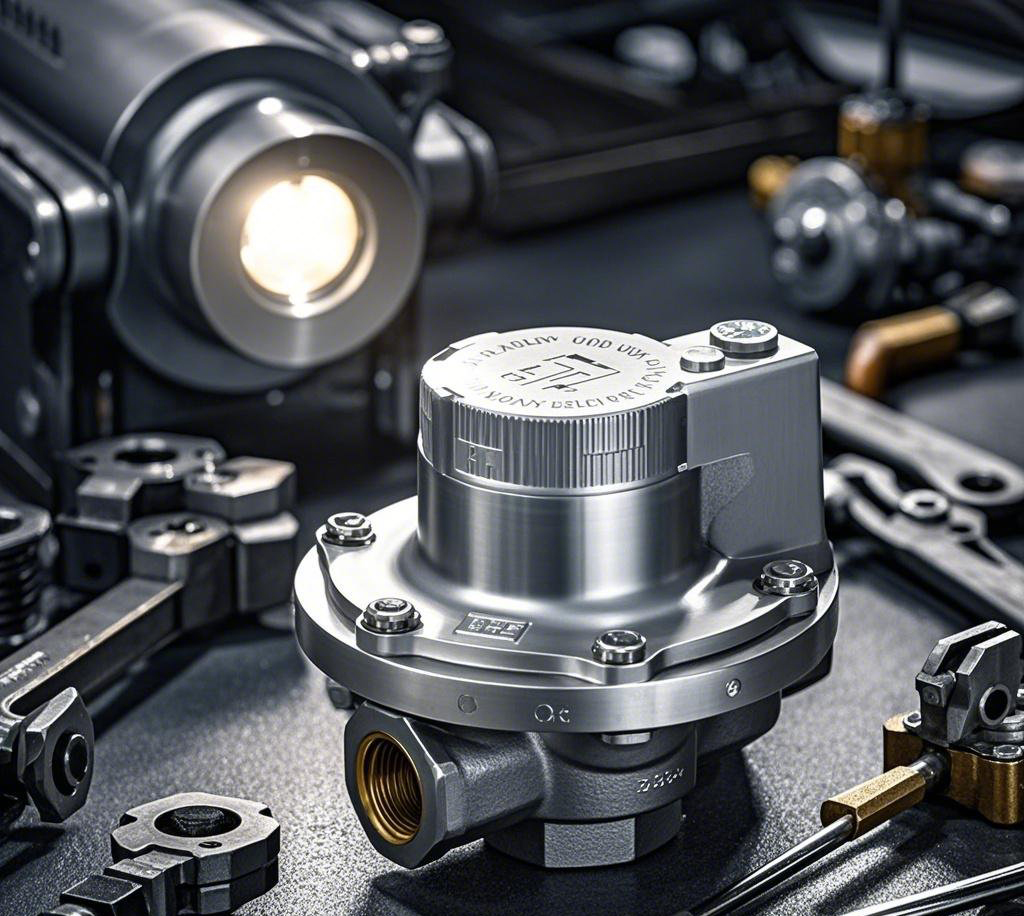

For industrial facility managers, it’s critical to understand common failures and solutions for full-stop safety valves. This article analyzes six typical problems in an easy-to-understand manner to help American readers quickly master maintenance techniques. Necessary terminology is retained in the text to facilitate technician search and review.

First, the safety valve reaches the pressure does not open

✓ Possible causes:

Pressure setting error: need to readjust the spring compression or adjust the weight position

Valve sticking: monthly manual air vent/drain test is recommended

Lever jamming (lever type): check and ensure that the lever activity is smooth, the weight position is correct

II. Early Opening Problems

✓ Quick diagnosis:

Calibrate pressure settings: verify settings with a professional pressure gauge

Spring deterioration: prioritize replacement over repeated adjustments (Model: ASTM A125 standard spring)

III. Pressure Continues to Rise After Pressure Relief

⚠️ Hazard Alert:

Selection error: check the valve displacement > equipment safety relief volume

Structural problems: check stem verticality and replace rusted springs if necessary

Exhaust pipe bottleneck: ensure that the cross-sectional area of the pipe ≥ valve discharge area

Fourth, abnormal leakage treatment

⛔ Prohibit operation with disease:

Cleaning steps: use the lifting wrench several times fully open flushing

Sealing surface repair: damage ≤ 0.1mm can be ground to repair, > 0.1mm need to be turned processing

Calibration check: focus on testing the stem verticality error (allowable range ± 0.5 °)

V. Valve does not reset fault

🔧 Quick repair:

Disassembly inspection: focus on cleaning the spring chamber and guide parts

Replacement criteria: spring permanent deformation > 5% immediately replaced

Six, frequency jump / vibration problems

📈 Specialized solutions:

Spring Stiffness: Use ASME Sec VIII recommended stiffness coefficients.

Adjustment Ring Setting: Determine optimal position through step test method

Piping Optimization: Ensure discharge back pressure <10% of set pressure

Troubleshooting and Maintenance Guide for Full Poppet Safety Valves