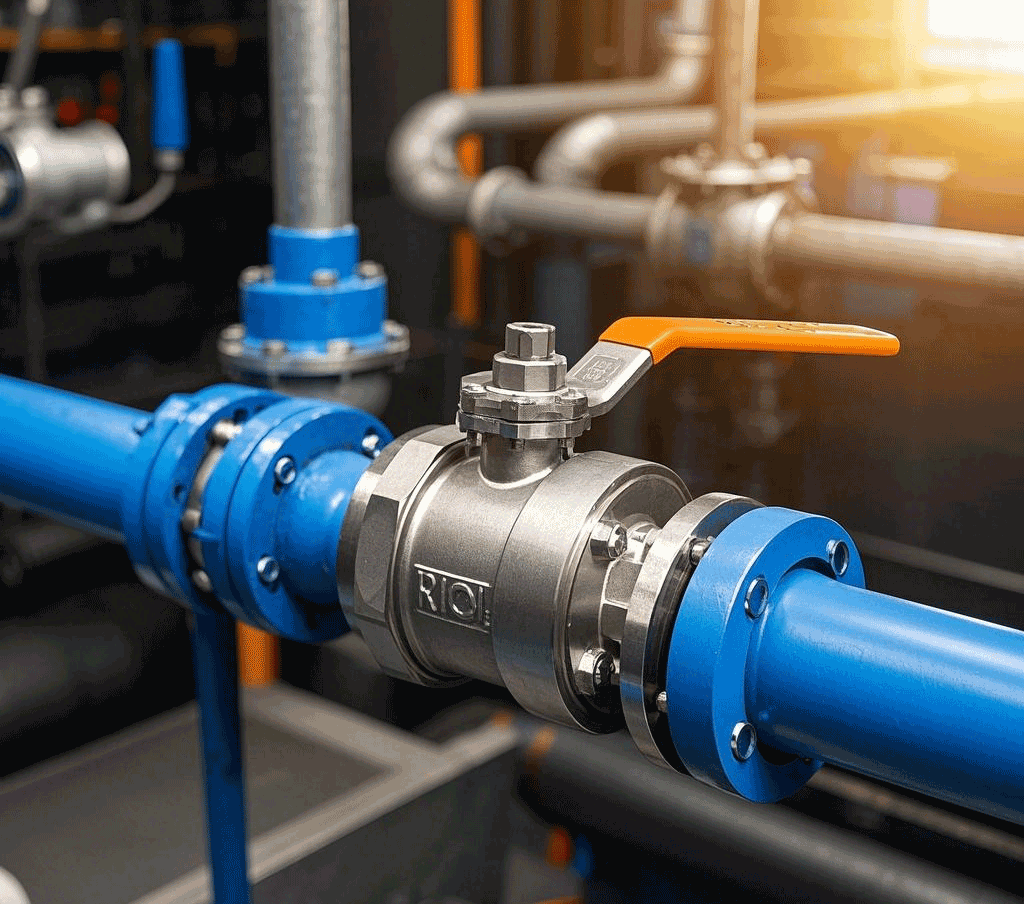

Ball valves: the flexible switching and flow control specialists in pipelines

In piping systems, one type of valve stands out for its unique design and efficient performance: the ball valve. Imagine a sphere with a circular channel that acts as a “master on/off switch” in the pipeline, controlling the flow of fluid with a simple twist. Today, we will unveil the mystery of the ball valve.

The working principle of the ball valve

The core component of the ball valve is a sphere with a round hole, the sphere is its “switch”. When the sphere rotates around the axis perpendicular to the pipeline, the hole will be aligned or misaligned with the import and export of the pipeline, thus realizing the opening and closing of the pipeline. This 90-degree rotation is not only simple and intuitive, but also very efficient.

Evolution from Plug Valves to Ball Valves

Actually, ball valves evolved from plug valves. They share a similar rotational action, but the difference is that the plug body of a plug valve is cylindrical, while the plug body of a ball valve is a sphere. This small change allows the ball valve to cut off fluid more evenly as it rotates, providing a higher sealing performance.

Ball Valve Throttling and Flow Control

While ball valves were originally used primarily to open and close pipes, as technology has evolved, they now have the ability to throttle and control flow. This means that by adjusting the angle of rotation of the ball, we can accurately control the flow of fluid in the pipeline to meet a variety of process needs.

Structure and Advantages of Ball Valves

The ball valve has a very compact structure, which makes it very easy to install and maintain. Its valve body cavities are completely equal, providing a low resistance, straight-through flow path for the fluid. This means that the fluid is able to maintain a high flow rate and flow as it passes through the ball valve, reducing energy consumption.

In addition, the ball valve is suitable for a wide range of working media, whether it is common water, solvents, acids, natural gas, etc., or oxygen, hydrogen peroxide, methane, ethylene, etc., which are subject to harsh working conditions, it can cope with them all. This is due to its high quality sealing materials and unique design.

Body types of ball valves

The body of a ball valve can be either monolithic or modular. Integral bodies have a robust structure and are suitable for high-pressure and high-temperature environments, while combination bodies are more flexible and can be customized according to specific application scenarios.

Overall, the ball valve has become a leader in piping systems with its unique design and efficient performance. It not only opens and closes pipelines with ease, but also accurately controls fluid flow to meet a variety of process needs. For users who need an efficient, flexible and reliable piping control system, ball valves are undoubtedly an ideal choice.