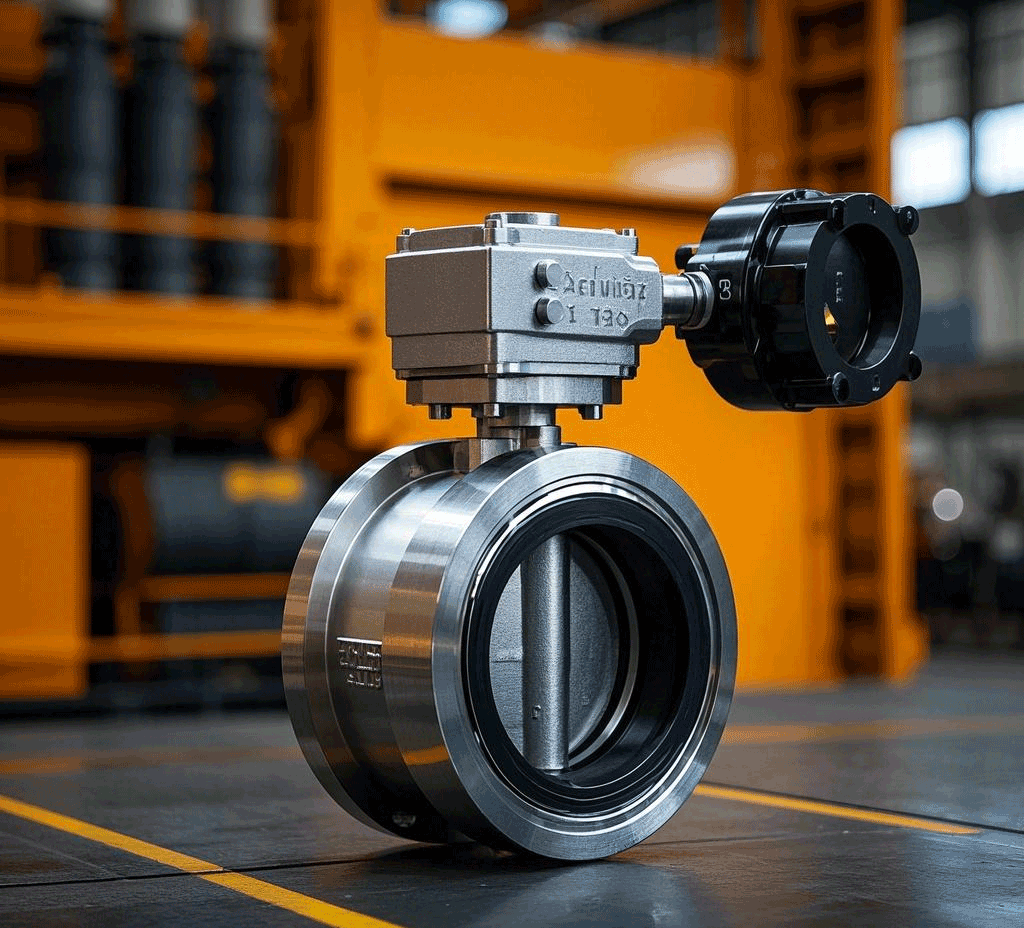

Butterfly valve: efficient “butterfly” switch in pipeline control

In the long history of valves, butterfly valve is undoubtedly a bright star. As early as the 1930s, the United States invented this unique valve. Subsequently, it was introduced to Japan in the 1950s, and was widely used in the 1960s. In China, the butterfly valve was popularized after the 1970s. Nowadays, butterfly valves have gradually taken the place of gate valves in piping systems of DN300 mm and above by virtue of their excellent performance.

Butterfly valves are favored worldwide thanks to their significant advantages. Compared with gate valves, butterfly valves have shorter opening and closing times, lower operating torque, less installation space and are lighter in weight. For example, for a DN1000 valve, a butterfly valve weighs about 2 tons, while a gate valve weighs 3.5 tons. In addition, butterfly valves are easy to combine with a variety of actuators, showing good durability and reliability.

However, butterfly valves are not perfect. In particular, rubber-sealed butterfly valves, when used as throttling, may produce cavitation if not used properly, resulting in peeling or damage to the rubber seat. To cope with this problem, metal-sealed butterfly valves have been developed internationally, effectively reducing the cavitation zone. In recent years, China has also successfully developed metal-sealed butterfly valves and achieved good results in practical applications. Meanwhile, Japan has also introduced the comb-shaped butterfly valve with cavitation resistance, low vibration and low noise, which further enriches the types of butterfly valves and application scenarios.

When selecting butterfly valves, we need to choose correctly according to the requirements of working conditions. Generally speaking, the life of rubber seal seat can reach 15-20 years under normal conditions, while metal seal seat can be used for 80-90 years. Therefore, when choosing butterfly valves, we need to fully consider the specific needs of the piping system and the operating environment.

The relationship between the opening of butterfly valve and the flow rate shows a linear proportional change. This means that if we use butterfly valves to control the flow, then its flow characteristics will be closely related to the flow resistance of the piping. For example, if two pipelines have exactly the same valve caliber, form, etc., but with different pipeline loss coefficients, then the difference in flow rate of the valve will be very large.

It is worth noting that when the butterfly valve is in a state with a large throttling amplitude, the back of the valve plate is prone to cavitation, which may damage the valve. Therefore, it is generally recommended that butterfly valves be used at openings other than 15°. In addition, when the butterfly valve is in a medium opening, the shape of the opening formed by the valve body and the front of the butterfly plate will be completely different on both sides, centered on the valve shaft. This may result in the formation of a nozzle-like opening on one side and a throttle orifice on the other. The flow rate on the nozzle side will be much faster than on the throttling side, creating a negative pressure under the valve on the throttling side, sometimes causing the rubber seals to come off.

When operating a butterfly valve, we also need to pay attention to the change in its operating torque. Due to the different opening and valve opening and closing directions, the value of the operating torque will be different. Especially for horizontal large-diameter butterfly valves, due to the influence of water depth, the torque generated by the difference between the head above and below the valve shaft should not be ignored. In addition, if an elbow is installed on the inlet side of the valve, a bias flow may be formed, thus increasing the operating moment. When the valve is in the middle opening, due to the role of water flow torque, the operating mechanism needs to have a self-locking function to ensure the stable operation of the valve.

Overall, butterfly valves have become a leader in pipeline control with their efficient, flexible and reliable performance. Whether as a switch or a throttling device, butterfly valves can show their unique advantages. However, when selecting and using butterfly valves, we also need to fully consider their specific application scenarios and working conditions to ensure that they can play the best performance.