In our daily lives, we often come into contact with two types of steam: saturated steam produced by boilers and superheated steam output from cogeneration plants. These two types of steam differ in their temperature and pressure characteristics, and therefore different factors need to be taken into account when selecting valves to control them. This article will explain how to select the appropriate steam solenoid valve for these two types of steam.

Saturated Steam: A Stable and Gentle Choice

Saturated steam generated by a boiler is relatively stable in temperature and pressure, usually with a temperature of no more than 250°C and an operating pressure of no more than 1.6 MPa. For this type of steam, we usually use soft-sealed steam solenoid valves.

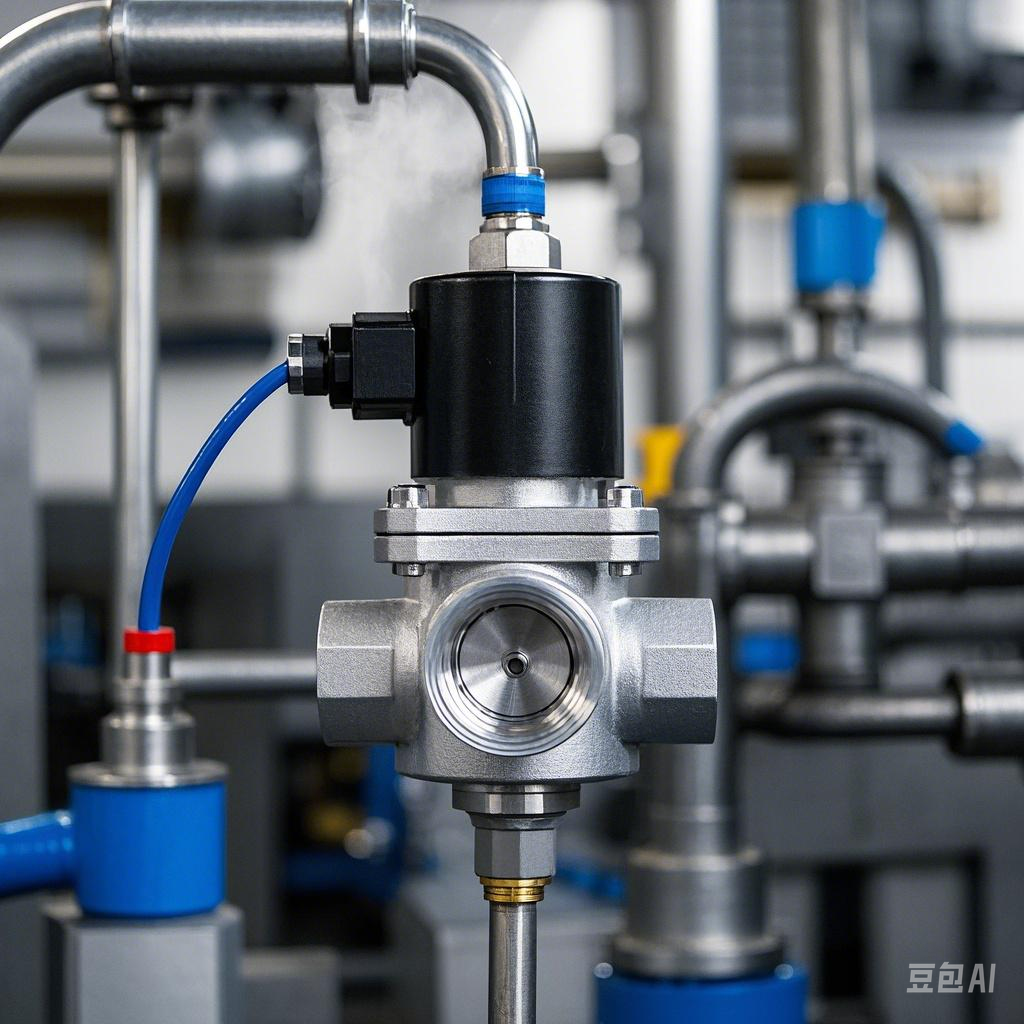

This type of solenoid valve consists of two major components, the secondary valve and the main valve, and adopts the pilot-operated secondary valve opening design. In order to ensure normal operation in a high-temperature environment, special high-temperature-resistant electrical materials and sealing materials are used for both the solenoid part and the sealing part, and a variety of heat-insulating measures are taken. In addition, the lubrication of fluid is skillfully utilized between the valve cup and the guiding sleeve to reduce wear and tear, thus prolonging service life.

What’s more, this soft-seal steam solenoid valve is unaffected by condensate in steam piping, enabling stable and reliable operation. In addition to steam control, it can be widely used in textiles, printing, chemicals, plastics, rubber, pharmaceuticals, food, building materials, machinery, electrical appliances, surface treatment and scientific research departments, as well as in automated control systems for bathrooms, cafeterias, air conditioning and other applications.

Superheated Steam: The Challenge of High Temperature and Pressure

Unlike saturated steam, the output of superheated steam from thermal power plants has a wide range of temperature and pressure variations, with temperatures up to 400°C or more, and working pressures below 4.0 MPa. For this high-temperature, high-pressure steam, we usually use hard-sealed steam solenoid valves.

Hard seal steam solenoid valves utilize a metal hard seal design, which improves the operating temperature and service life of the product. Fluid lubrication is also utilized between the valve cup and guide sleeve to reduce wear. This type of solenoid valve has a wide range of universal media, and can be used not only for steam, but also for fluids such as water, light oils, heavy oils, and non-corrosive gases.

Hard seal steam solenoid valves play an important role in the power station pumping pipeline trap system and the exhaust system of the evaporator. It is capable of two-position automatic adjustment and remote control of the medium in the pipeline to ensure stable operation of the system.

Operating Condition and Selection

Whether soft seal or hard seal steam solenoid valves, they have two types of working status: normally closed type and normally open type. Normally closed solenoid valves close when the power is off and open when the power is on, while normally open solenoid valves open when the power is off and close when the power is on. Depending on your specific needs and application scenarios, you can choose the right type of solenoid valve and operating state.

In short, choosing the right solenoid valve for steam is critical to ensuring the stable operation of your steam system. By understanding the characteristics of different types of steam and how solenoid valves work, you can find the most appropriate solution for your steam application.