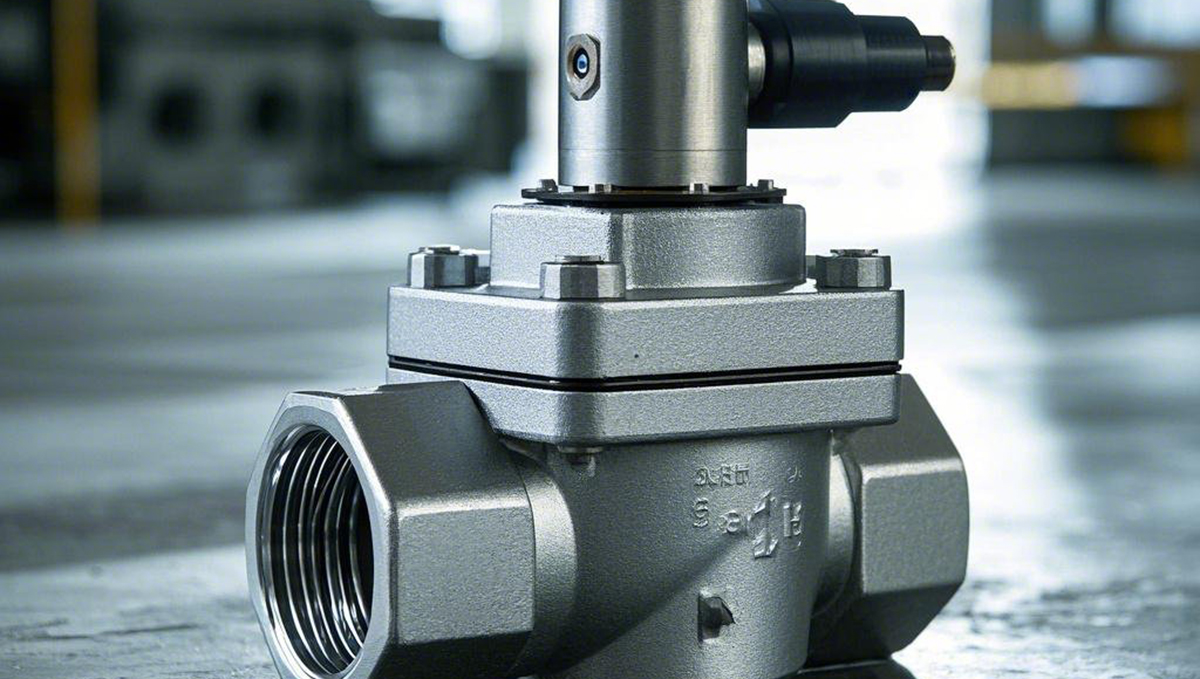

In the industrial field, solenoid valves play a crucial role, they are like the “switch” of the industrial control system, responsible for adjusting the direction of flow of media (such as liquids, gases, etc.), flow, speed and other key parameters. So, what exactly is a solenoid valve, and how it works?

Simply put, the solenoid valve is a kind of industrial equipment that utilizes the electromagnetic effect for control. Its core operating principle relies on the electromagnetic force generated by a solenoid coil. When the solenoid coil is energized, this electromagnetic force drives the valve’s closing member (usually a spool or plate) to move, thus changing the valve’s open or closed state. All of this is precisely controlled by circuit elements such as relays, ensuring precision and flexibility of control.

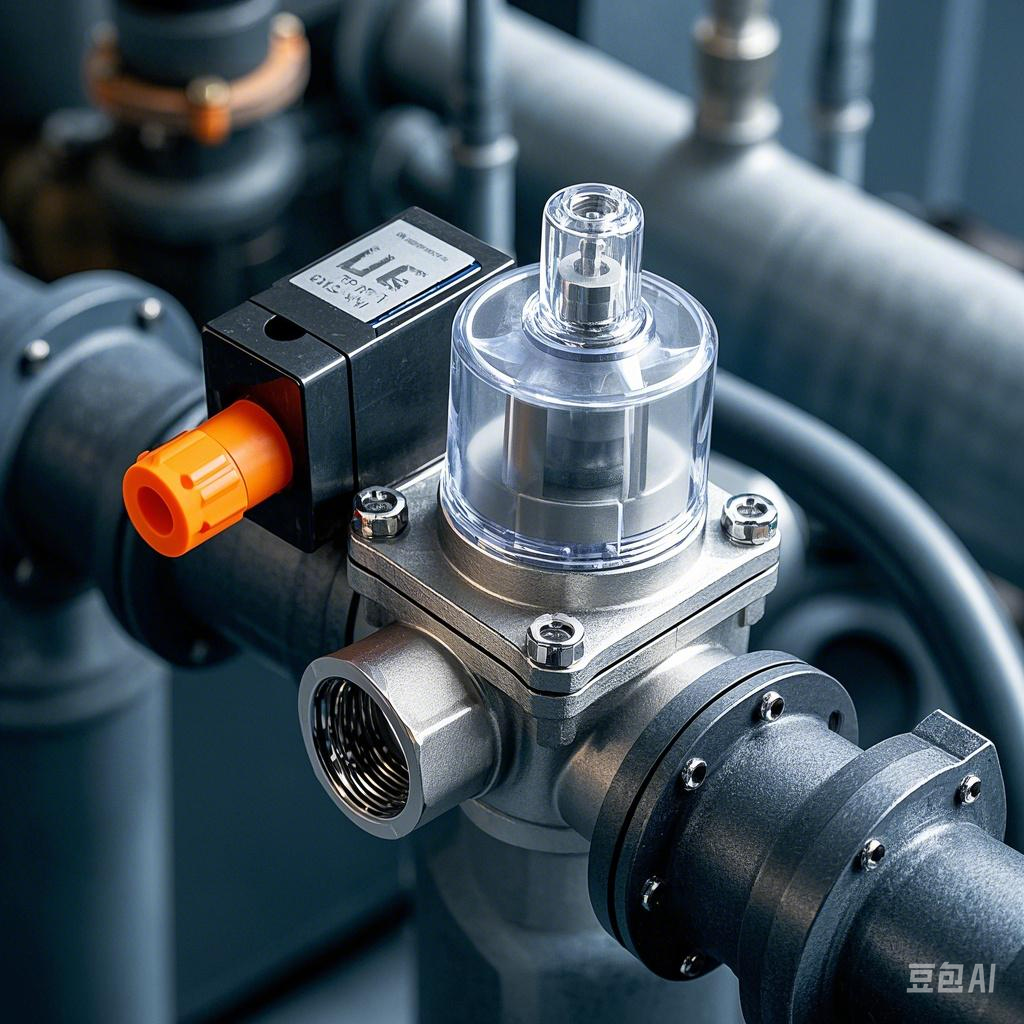

There are many different types of solenoid valves, and each type plays a unique role in a different location of the control system. For example, check valves only allow the medium to flow in one direction, safety valves can automatically release the pressure to protect the system when the pressure is too high, directional control valves are used to change the direction of the flow of the medium, and speed regulating valves can adjust the flow rate of the medium.

From the working principle, solenoid valve is mainly divided into three categories:

Direct-acting solenoid valve

Imagine, when you energize the solenoid coil, it is like an invisible “hand”, the valve’s closing parts from the valve seat up, the valve is open. And when you cut off the power, this “hand” disappears, the spring and the closed parts of the valve seat pressure back, the valve is closed. This type of solenoid valve in a vacuum, negative pressure or zero-pressure environment can also work properly, but its diameter (i.e., the size of the valve opening) is generally not more than 25 millimeters.

Step-by-step direct-acting solenoid valve

This type of solenoid valve combines the advantages of the direct-acting and pilot-operated types. When there is no pressure difference between the inlet and outlet, when energized the electromagnetic force will directly lift the pilot small valve and the main valve closure, and the valve opens. And when there is a pressure difference, the electromagnetic force will open the pilot valve first after energizing, which makes the pressure of the lower chamber of the main valve rise and the pressure of the upper chamber fall, and the main valve is pushed open by using this pressure difference. When the power is off, the pilot valve will use the spring force or medium pressure to push the closing member to move downward, so that the valve is closed. This kind of solenoid valve can work reliably under zero differential pressure, vacuum or high pressure environment, but the power is larger and needs to be installed horizontally.

Pilot operated solenoid valve

The working principle of this kind of solenoid valve is more ingenious. When energized, the electromagnetic force opens the pilot orifice, causing a rapid drop in pressure in the upper chamber. In the closing parts around the formation of a top low high pressure difference, this pressure difference is like an invisible force, pushing the closing parts upward movement, the valve is open. When the power is off, the spring force will close the pilot hole, the pressure of the inlet through the bypass hole quickly into the chamber, formed around the closing member of a lower-low upper-high differential pressure, pushing the closing member downward movement, the valve is closed.

Overall, solenoid valves are an integral part of industrial control systems. They ensure the smooth running of industrial processes through precise control and adjustment. No matter which type of solenoid valves are used, they play an important role in their respective positions and contribute to the development of industry.