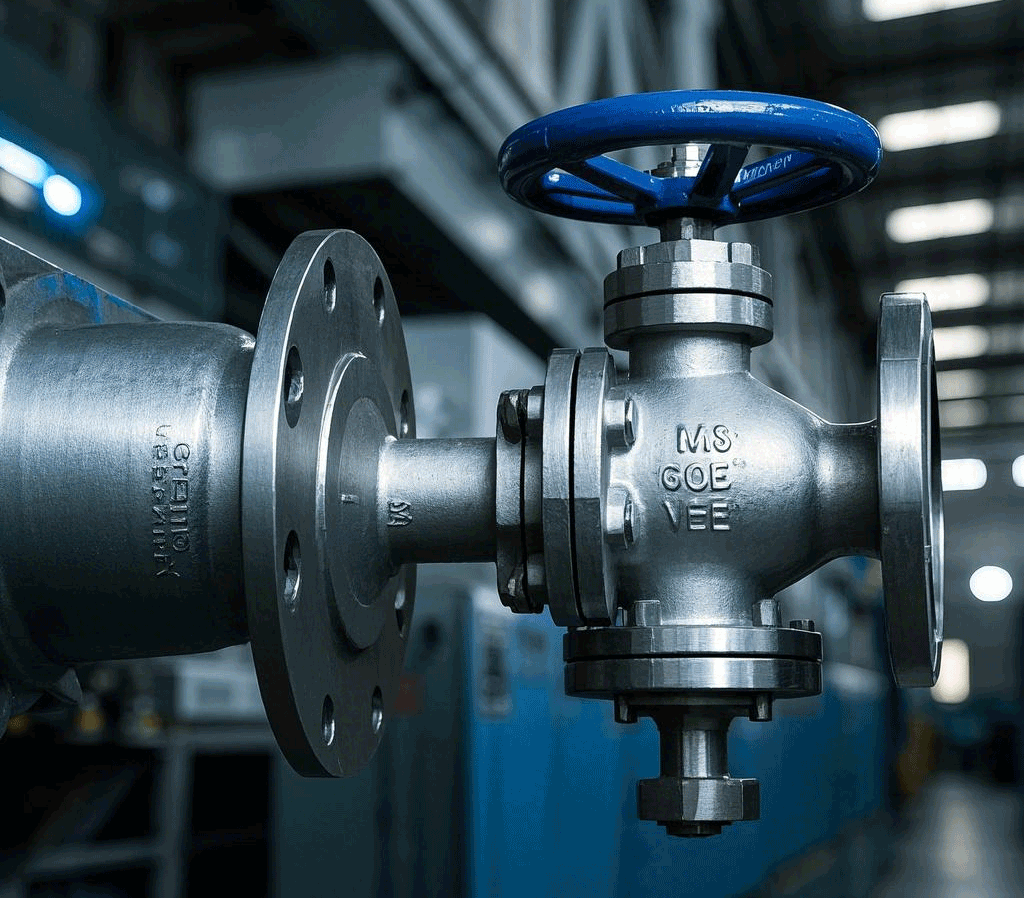

For a long time, the common gate valves on the market are commonly characterized by leakage or rust. However, the resilient seated gate valve, which is produced with advanced European rubber and valve manufacturing technology, has successfully overcome the defects of poor sealing and rusting of traditional gate valves.

Through its unique elastic gate design, the resilient seated gate valve is able to produce a small amount of elastic deformation, and this compensating effect ensures that the valve achieves excellent sealing effect. The valve has significant advantages such as easy switching operation, reliable sealing performance, excellent elastic memory and long service life. Therefore, it is widely used in various piping systems such as water, sewage treatment, construction, petroleum, chemical, food, medicine, textile, electric power, ship, metallurgy and energy systems, as an important device for regulating and cutting off fluids.

The significant features of gate valve:

Light weight: the body of the gate valve is made of high-grade ductile iron material, which reduces its weight by about 20% to 30% compared with the traditional gate valve, which makes the installation and maintenance work more convenient.

Flat-bottomed gate seat design: After the traditional gate valve is passed through the water to wash the pipe, it is often because of the foreign objects (such as stones, wood, cement, iron filings and debris, etc.) silted up in the groove at the bottom of the valve, which leads to the valve can not be tightly closed, thus resulting in the phenomenon of water leakage. The bottom of the resilient seated gate valve adopts the same flat bottom design as that of the water pipe, which is not easy to cause the accumulation of debris and ensures the unobstructed flow of fluids.

Overall rubber coating technology: The gate plate adopts high-quality rubber for overall internal and external rubber coating treatment. With the help of Europe’s first-class rubber vulcanization technology, the vulcanized gate plate can maintain precise geometric dimensions. At the same time, the combination between rubber and ductile iron gate is firm and reliable, not easy to fall off, and has good elastic memory.

Precision casting valve body: the valve body is manufactured by precision casting process, the precise geometry ensures that the valve body can achieve good sealing without any finishing.

In summary, resilient seated gate valve with its excellent performance and wide range of applications, has become a highly favored valve products on the market.