This type of valve plays a key role in ensuring that fluid can only flow in one direction, while effectively preventing reverse flow. This type of valve usually operates automatically: when fluid flows in one direction, the pressure generated causes the valve to open; when fluid tries to flow in the opposite direction, it is the combination of the pressure of the fluid and the weight of the valve flap itself that causes the valve flap to fit tightly against the valve seat, thus cutting off the flow.

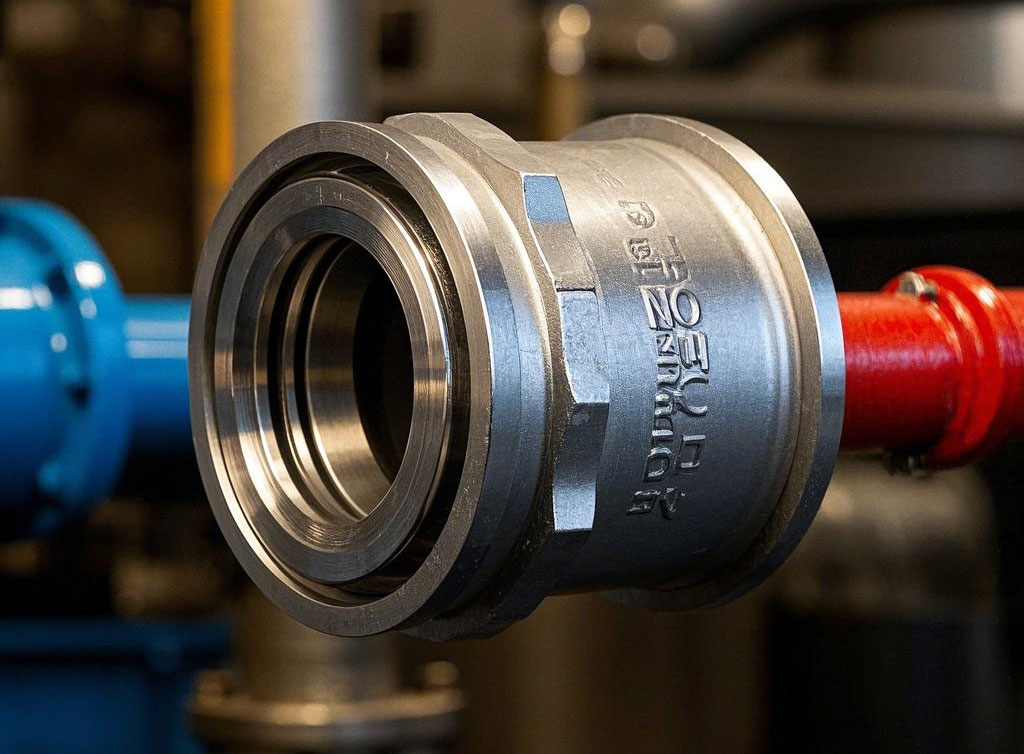

The check valve is just such a valve, which contains two types: swing-opening and lifting type. The design of a swing check valve includes a hinged mechanism and a flap, similar to a door, which rests freely on the sloping seat surface. To ensure that the valve flap fits accurately on the seat surface every time, the valve flap is cleverly designed on the hinge mechanism so that the valve flap has enough room to rotate and make true, full contact with the seat. The choice of material for the valve flap is very flexible and can be all-metal or metal inlaid with leather, rubber or other synthetic materials, depending entirely on the specific needs of the application. When a swing check valve is fully open, there is little or no obstruction to fluid pressure, so there is relatively little pressure loss through the valve.

The flap of a lift check valve, on the other hand, sits on the seat sealing surface of the valve body. Other than the fact that the flap is free to rise and fall, the rest of this valve is very similar to a globe valve. When fluid pressure acts on the valve flap, the valve flap will be lifted from the seat sealing surface; and when the medium flows back, the valve flap will fall back to the valve seat to cut off the flow. Depending on the conditions of use, the valve flap can be all-metal, or the flap frame can be inlaid with rubber gasket or rubber ring. Similar to globe valves, the passage of fluid through a lift check valve is relatively narrow, so the pressure loss through a lift check valve will be slightly greater than that of a swing check valve, and the flow rate of a swing check valve is less restricted.

In the process of using check valves, some common failures may be encountered, mainly including valve flap crushing and media backflow.

Valve broken valve is usually the cause: check valve before and after the media pressure is close to the balance of the state, but each other “pull”, resulting in frequent collision with the valve seat valve flap. In this case, if the valve is made of certain brittle materials (such as cast iron, brass, etc.), it will be easily broken. In order to prevent this situation, we can choose to use the valve flap is tough material check valve.

The reason for the backflow of the medium may be the sealing surface is damaged or entrapped in impurities. Repairing the sealing surface and cleaning impurities can effectively prevent the medium backflow.