Pressure reducing valves play a vital role in fire protection water supply and sprinkler systems. Today, we will work together to understand the working principle of the pressure reducing valve and its setting requirements, in order to better understand and apply this key component.

I. Principle of operation

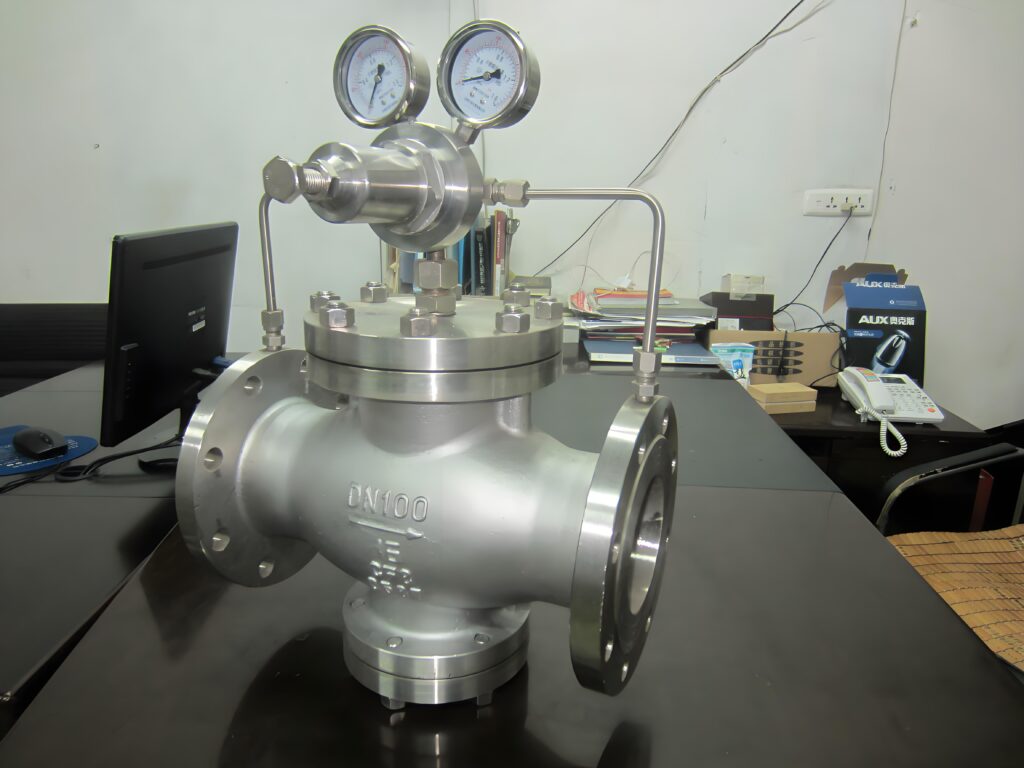

- Pilot-Operated Pressure Reducing Valve

Pilot Operated Pressure Reducing Valve changes the flow rate and kinetic energy of the fluid in the pipeline by adjusting the throttling area, thus generating pressure loss and achieving pressure reduction. It utilizes the hydraulic principle for fine control and adjustment, so that the pressure fluctuation inside the valve is balanced with the spring force to ensure that the pressure after the valve in the pipeline remains constant within a certain error range. This kind of valve is like an intelligent local pressure regulator that can automatically adjust the outlet pressure to a preset range according to the inlet pressure. - Proportional Pressure Reducing Valves

Proportional pressure reducing valves control the pressure after the valve according to a numerical ratio. There is a certain ratio between pre-valve pressure and post-valve pressure, such as 2:1 or 3:1. When the pre-valve pressure changes, the post-valve pressure changes proportionally, but the ratio to the pre-valve pressure remains constant. This characteristic of pressure reducing valve makes it able to provide stable pressure reduction under different pressures.

Setting Requirements

In order to ensure the effective operation and easy maintenance of pressure reducing valves, the following are the key setting requirements:

Location Selection: The pressure reducing valve should be set in front of the inlet of the alarm valve group. If two or more alarm valve groups are connected, additional backup pressure reducing valves should be installed.

Strainer Installation: Install a strainer at the inlet of the pressure reducing valve to prevent contaminants from clogging the pressure reducing valve. The orifice mesh of the strainer should be of moderate diameter and the overflow area should be large enough to ensure smooth fluid flow.

Pressure gauge configuration: Install pressure gauges before and after the filter and pressure reducing valve to monitor pressure changes at any time. The dial diameter of the pressure gauge should be large enough and the range should be appropriate to provide accurate readings.

Control Valve Configuration: Install control valves before and after the filter and pressure reducing valve to facilitate maintenance and replacement of the pressure reducing valve to reduce system drain time and water shutdown impact.

Drain Valve and Test Connection: A pressure test drain valve and flow detection test connection or flow meter should be provided after the pressure reducing valve for performance testing and maintenance.

Installation direction: Vertical installation of the pressure reducing valve water flow direction should be down; proportional pressure reducing valve should be installed vertically, adjustable pressure reducing valve should be installed horizontally.

Protection locking device: Pressure reducing valves should be equipped with a device to protect or lock the regulating fittings to prevent misoperation.

Piping requirements: The piping section connected to the pressure reducing valve should be free of air blockage and air resistance to ensure smooth fluid flow.

Precautions

The performance of the pressure reducing valve requires that the direction of water flow remains unchanged. Installation must be carried out in strict accordance with the direction indicated by the pressure reducing valve to avoid performance degradation or failure.

The function of the strainer is to prevent impurities in the piping network from entering the inside of the pressure reducing valve, causing blockage or affecting performance. Therefore, it is vital to install a strainer on the inlet side of the pressure reducing valve.

Control valves before and after the pressure reducing valve facilitate maintenance and replacement operations, reducing system downtime and area of influence.

Vertical installation of proportional pressure reducing valves helps to ensure reliable operating performance and extended service life. Horizontal installation requires care to prevent clogging of the breather orifice.

Installation of pressure gauges can be convenient to check the pressure reducing effect of the pressure reducing valve and the working condition is in line with the design requirements.

Third, the pressure reducing valve debugging

In order to ensure the normal operation of the pressure reducing valve, the following debugging should be carried out:

The dynamic and static pressure before and after the valve should meet the design requirements.

Pressure reducing valve flow should meet the design requirements, and in the design of 150% of the flow rate to maintain a stable pressure reduction effect.

Pressure reducing valve in different flow should not appear in the phenomenon of noise significantly increased.

Test the pressure reducing valve after the valve dynamic and static pressure difference should meet the design requirements.

Fourth, the pressure reducing valve maintenance

Regular maintenance and inspection is essential to ensure the long-term stable operation of the pressure reducing valve:

Monthly pressure reducing valve group for a water discharge test, and record the pressure value before and after the pressure reducing valve. If there is any discrepancy, appropriate measures should be taken to adjust and repair.

Conduct a comprehensive test of the flow and pressure of the pressure reducing valve once a year to ensure that its performance meets the design requirements.

By gaining a deeper understanding of the working principle and setting requirements of pressure reducing valves, we can better apply this key component to ensure the stable operation of fire protection water supply and automatic sprinkler systems.