Ball valves, a device that plays a key role in piping systems, come in many varieties, but their basic structure is much the same. Their core component is a round ball core, by rotating 90 degrees to realize the valve open and close. This article will provide you with an in-depth analysis of the structural characteristics of the O-type ball valves and V-type ball valves and their advantages, to help you better understand and choose the right ball valve for your needs.

First, O-type ball valves: a simple and efficient choice

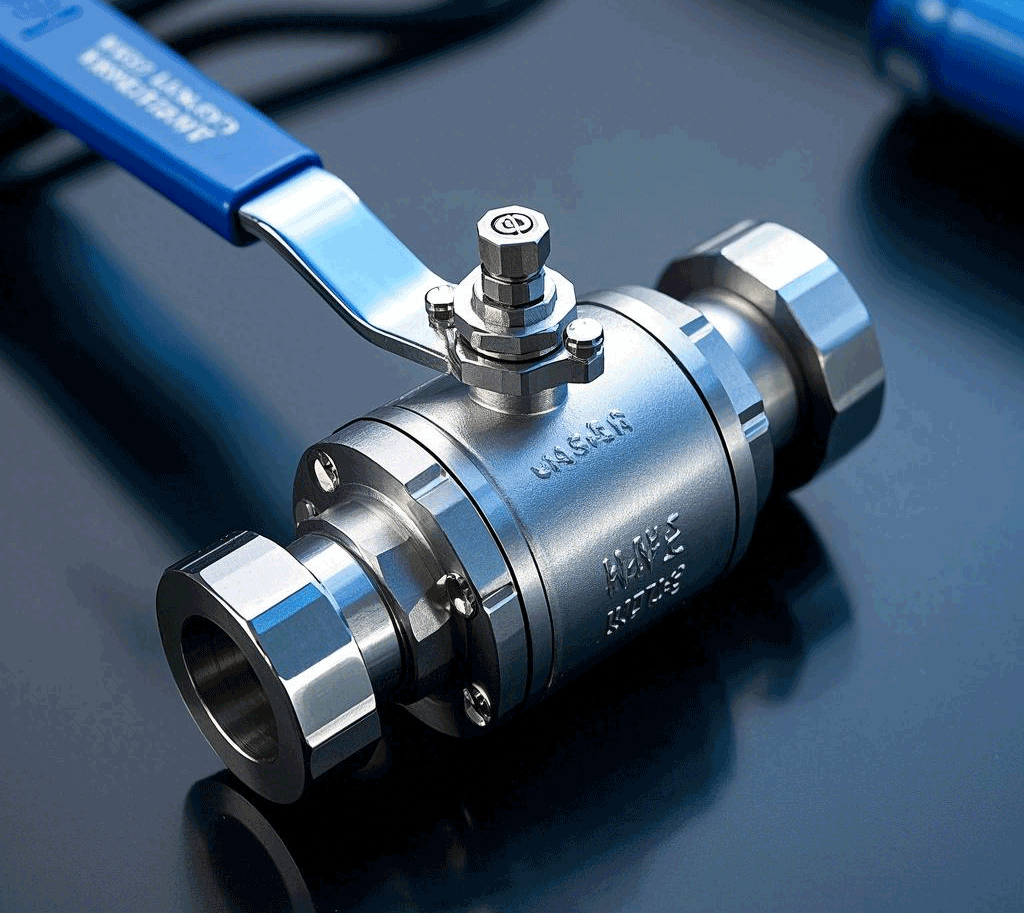

O-ball valves have a ball with a center through-hole installed inside the valve body, and the diameter of this through-hole is equal to the diameter of the pipeline. The sphere can rotate freely in the sealing seat, while the sealing relies on the annular elastomer on both sides of the pipeline direction.

Small fluid resistance: O-type ball valves have two structures – through-hole and reduction. But no matter which structure, its flow resistance coefficient is relatively small. Especially straight-through (full-flow type) ball valves, whose channel diameter is equal to the inner diameter of the pipeline, the resistance loss is almost negligible.

Swift switching: only need to rotate 90 degrees, O-type ball valves can complete the full open or full closed action, easy and fast operation.

Good sealing performance: most of the O-type ball valve seat are made of polytetrafluoroethylene (PTFE) and other elastic materials, this soft sealing design ensures good sealing performance.

Long life: PTFE material has good self-lubrication, and the ball of the friction coefficient is small, so greatly extend the service life of the ball valve.

High reliability: the sealing vice of O-type ball valve is not easy to be abraded or sharply worn, and after the valve stem is changed to internal mounting type, it eliminates the potential danger of accidents caused by fluid pressure. In addition, anti-static, fire-resistant structure of the ball valve can also be used to transport oil, natural gas and other pipelines.

Second, the V-ball valve: regulation and cut off the ability to hand

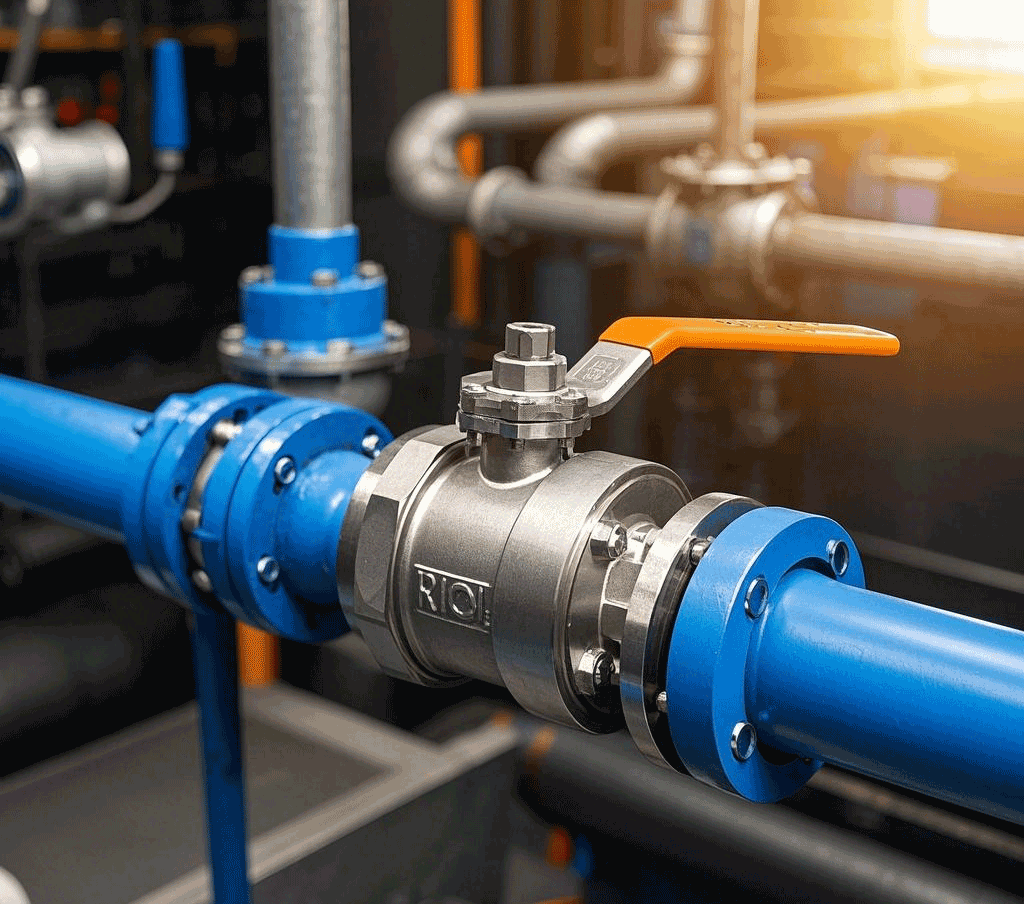

V-ball valve spool with V-shaped structure, this design makes it has a large circulation capacity, adjustable range, shear force and close tightly and so on. Especially suitable for handling fluids containing fibrous substances.

Cutting off impurities: During the rotation of the ball, the V-type cutter and the valve seat are cut off, effectively cutting off the fibers and solid substances in the fluid, avoiding the problem of fibrous impurities stuck in the closure.

Easy disassembly and installation: V-ball valve usually adopts flange connection form, no special tools can be easily disassembled and installed, maintenance is also simple and easy.

Superior regulating performance: V-ball valves can realize flow regulation, according to the different angles of the V-ball, can realize different degrees of proportional adjustment. With the valve actuator and positioner supporting the use of more accurate proportional adjustment can be realized.

Widely used: V-ball valves are small in size, can be installed vertically and horizontally, and are suitable for controlling a wide range of media such as gas, steam and liquid. Its right-angle rotary structure and double bearing design ensures that the starting torque is small, high sensitivity and fast sensing speed.

In summary, whether it is O-type ball valves or V-type ball valves, they all play an irreplaceable role in their respective fields. Choosing the ball valve that suits your needs will bring your piping system a more efficient, reliable and safe operation experience.

O-type ball valve and V-type ball valve difference