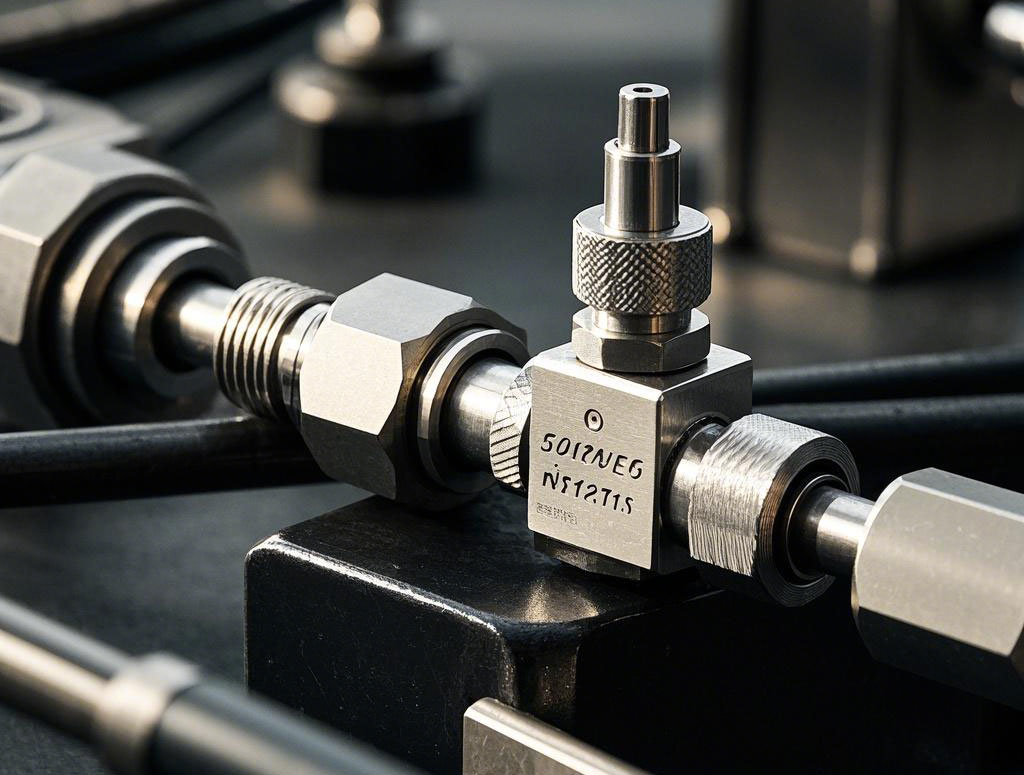

needle valves, as a precision trim valve, are unique in that their plugs are designed as needles, specifically designed to accurately regulate gas flow. The design of this valve requires that the orifice be able to be adjusted gradually and continuously from fully closed to maximally open, and the needle shaped plug is the key to accomplishing this function.

Imagine a long, hardened steel needle, the plug in a needle valve. With its finely shaped needle tip, it enables small but precise adjustments to the air flow. The valve seat, meanwhile, is carefully crafted from soft materials such as tin and copper to ensure a tight fit with the valve plug.

The seal between the valve plug and seat is achieved by the close fit of their tapered surfaces. There are two common tapers for this taper design: a 1:50 taper and a 60 taper angle. In either taper, the tapered surfaces are finely ground to ensure optimum sealing and adjustment accuracy.

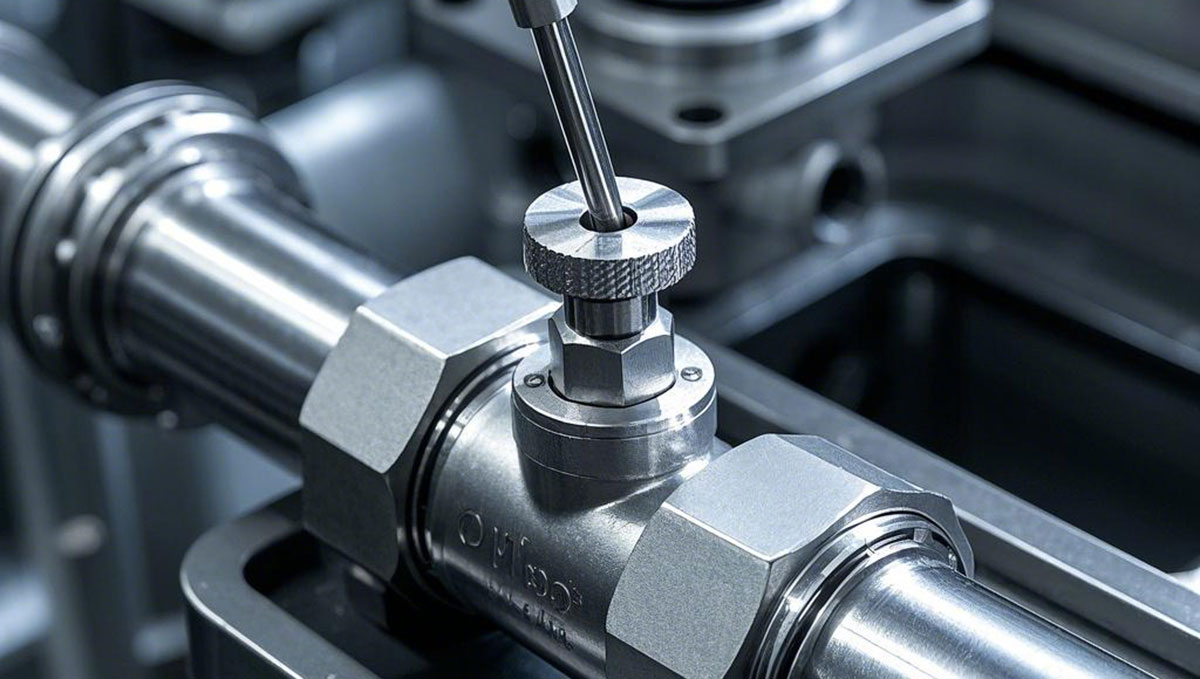

In addition to the sealing between the valve plug and the valve seat, the sealing between the valve stem and the valve seat is also crucial. In Needle valves, this sealing task is undertaken by the bellows. With their unique structure and elasticity, bellows can effectively prevent gas leakage and ensure stable valve operation.

Needle Valves: Trimming Valve Solutions for Precise Regulation of Air Flow