In piping systems, one type of valve plays a crucial role – the check valve, which is also often referred to as a one-way valve or a backstop valve. Its main function is to prevent the medium in the pipeline backflow, to ensure that the medium can only flow in one direction, so as to avoid the potential risk of accidents. Pump suction end of the bottom valve, also belongs to a check valve.

The working principle of the check valve is quite ingenious, its opening and closing parts can rely on the flow of the media to open or close the force itself. When the normal flow of media, the valve is open; once the medium tries to backflow, the valve is quickly closed, effectively preventing the occurrence of backflow phenomenon. As a member of the automatic valve class, check valve in the media flow in one direction on the pipeline plays an irreplaceable role.

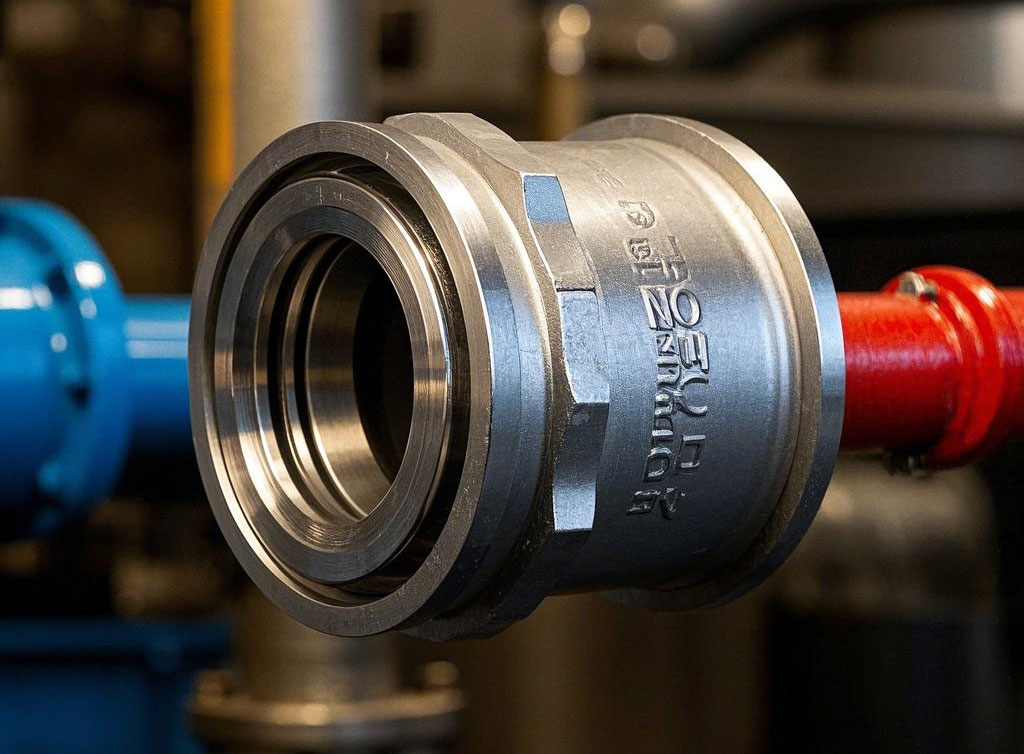

From the structural point of view, check valves are mainly divided into three types: lift, swing and butterfly. Lift check valves can be further subdivided into vertical and horizontal types. Swing check valves, on the other hand, include single-valve, double-valve and multi-valve designs. Butterfly check valves, on the other hand, are of straight-through construction. In addition, these check valves differ in their connection forms, including threaded, flanged and welded connections.

When installing check valves, there are several key points to note:

Avoid bearing weight: Do not subject the check valve to additional weight in the pipeline. For large check valves, independent support should be used to ensure that they are not affected by the pressure generated by the piping system.

Direction of media flow: When installing, make sure that the direction of media flow is the same as the direction of the arrow labeled on the valve body, which is the key to ensure the normal operation of the check valve.

Vertical and horizontal installation: lift vertical flap check valves should be installed in vertical piping, while lift horizontal flap check valves should be installed in horizontal piping to ensure its best performance.

Particularly worth mentioning is the vertical check valve, which is widely used in the system of preventing medium backflow. For example, vertical check valves play an important role in the outlet of water pumps, hot water replenishment end and the suction end of centrifugal water pumps. If the vertical check valve is not installed, the pump may be damaged by the huge impact of high-speed backflow water when it is suddenly shut down. As for the suction side of centrifugal pumps, if there is no installation of vertical foot valve, every time before the start of the pump need to carry out the tedious operation of filling the pump.

In summary, the check valve is an indispensable safety guard in the pipeline system, it can ensure that the media flow in one direction, effectively preventing the occurrence of backflow phenomenon. When installing and using check valves, it is important to follow the correct operating instructions to ensure optimum performance and long-term reliability.

Installation Precautions for Check Valves