An often overlooked issue when using forged steel gate valves is the greasing pressure. During the greasing operation, the greasing pressure will show regular peaks and valleys. If the pressure is too low, it may lead to seal leakage or safety valve failure; while too high a pressure may cause the grease injection port to be clogged, the grease inside the seal to be hardened, or the seal to be stuck tightly with the valve ball or valve plate.

When the grease injection pressure is too low, the grease tends to flow more into the bottom of the valve cavity, which is especially common in small gate valves. Conversely, if the grease injection pressure is too high, first check the grease injection nozzle to see if the grease hole is clogged; if it is, it needs to be replaced. Alternatively, it may be due to hardening of the grease, which would require the use of a cleaning solution to repeatedly soften the failed sealing grease and inject new grease for replacement.

It is worth noting that the type and material of the seal also affects the greasing pressure. Different sealing forms require different grease injection pressure, generally speaking, hard sealing grease injection pressure is higher than soft sealing.

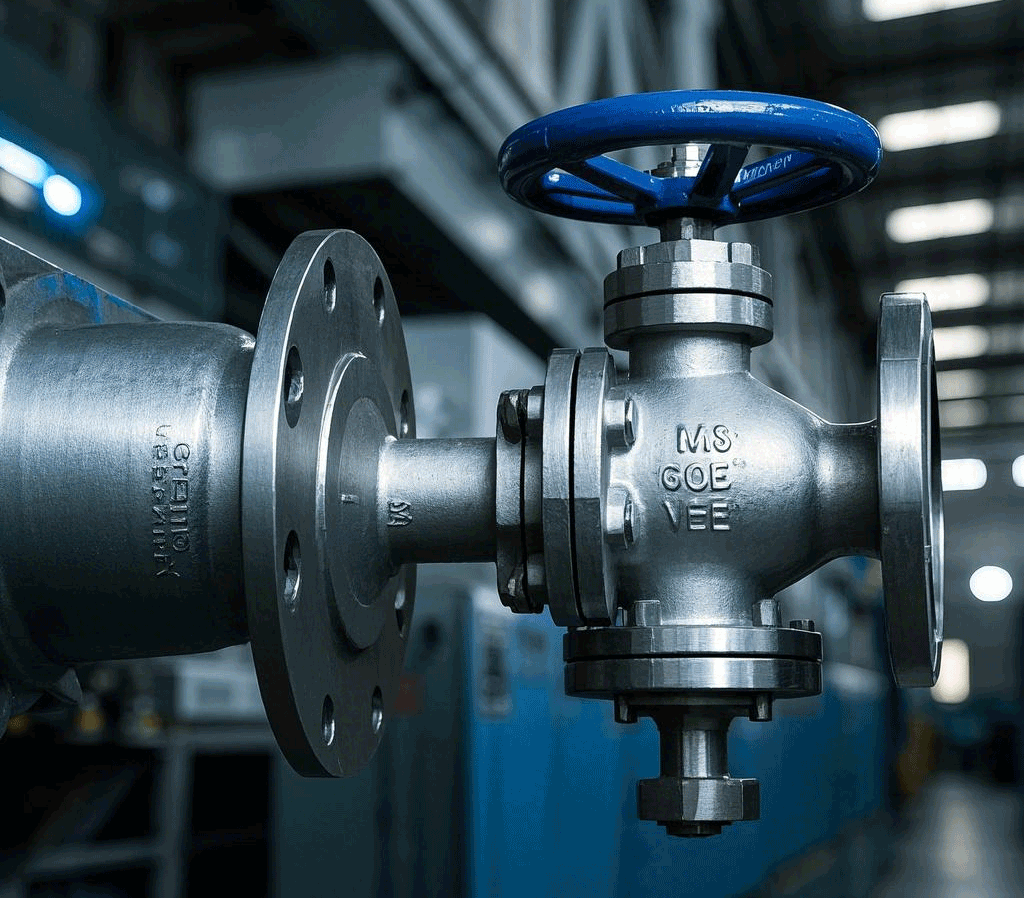

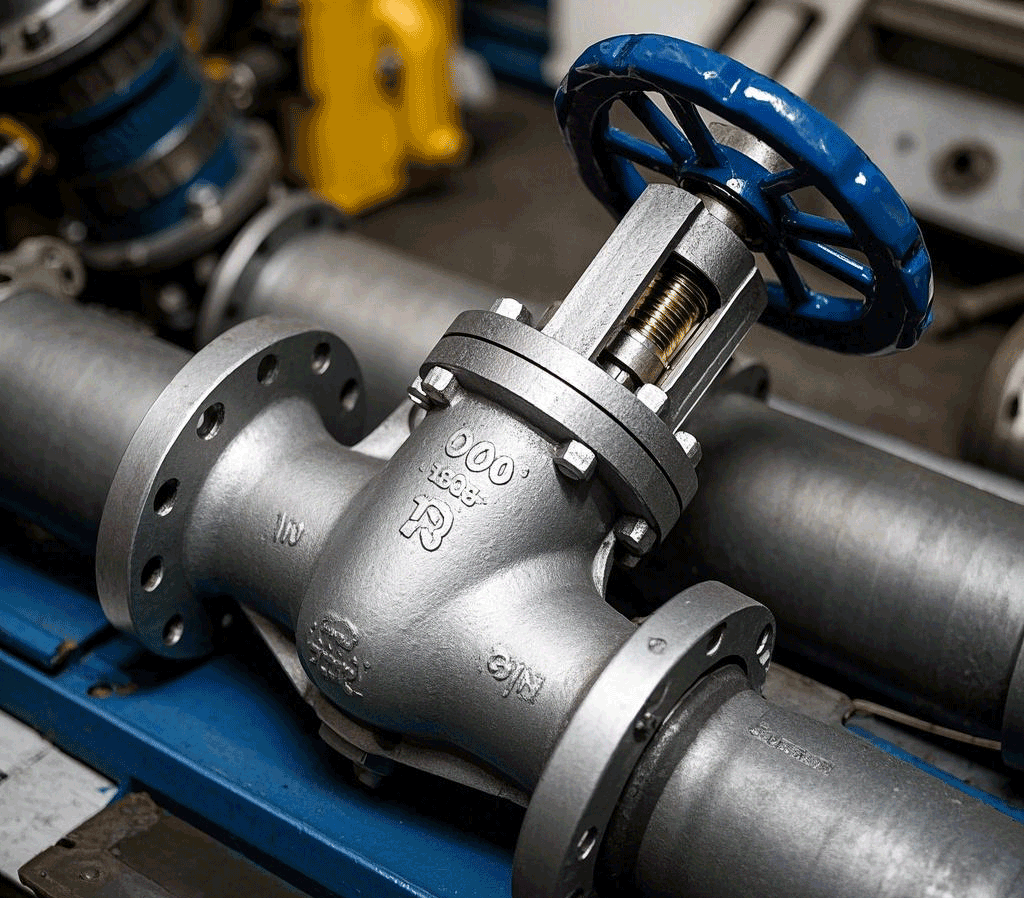

Forged steel gate valves are suitable for small diameter pipelines with working pressure ranging from Class150 to 2500 and working temperature ranging from -29℃ to 425℃ (carbon steel) or from -29℃ to 500℃ (stainless steel), used to cut off or connect the fluid medium in the pipeline. By choosing different materials, forged steel gate valve can be widely used in water, steam, oil, nitric acid, acetic acid, oxidizing media and urea and other media.

Forged steel gate valve classification and characteristics

Gate valves have a variety of classifications according to different designs, including parallel gate valves, wedge gate valves, lift gate valves, rotary stem gate valves, quick opening and closing gate valves, indented gate valves and flat gate valves. Forged steel gate valve is characterized by low fluid resistance, can withstand a wide range of pressure and temperature range, medium flow direction is not restricted, and has good sealing performance.

Construction and installation points

The installation position, height and import and export direction of the gate valve must be carried out in strict accordance with the design requirements to ensure that the connection is firm and tight.

If the gate valve is installed on the insulation pipe, the handle must be kept in the upward direction.

Before installing the gate valve, an appearance check must be carried out to ensure that the nameplate of the valve complies with the provisions of the national standard GB 12220 “General Valve Marking”. For valves with a working pressure of more than 1.0 MPa or playing a cut-off role in the main pipe, strength and tightness performance tests should be carried out before installation to ensure that they are qualified before use. Strength test pressure should be 1.5 times the nominal pressure, duration of not less than 5 minutes, the valve shell and packing should be no leakage. The pressure of the tightness test shall be 1.1 times the nominal pressure, and the test time and standard shall be in accordance with the requirements of GB 50243 to ensure that there is no leakage on the sealing surface of the valve flap.

Due to its excellent performance and wide range of applications, forged steel gate valve is widely used in pipeline industries such as petroleum, chemical, metallurgy, machinery, electric power and military, etc., and is highly trusted and praised by users.