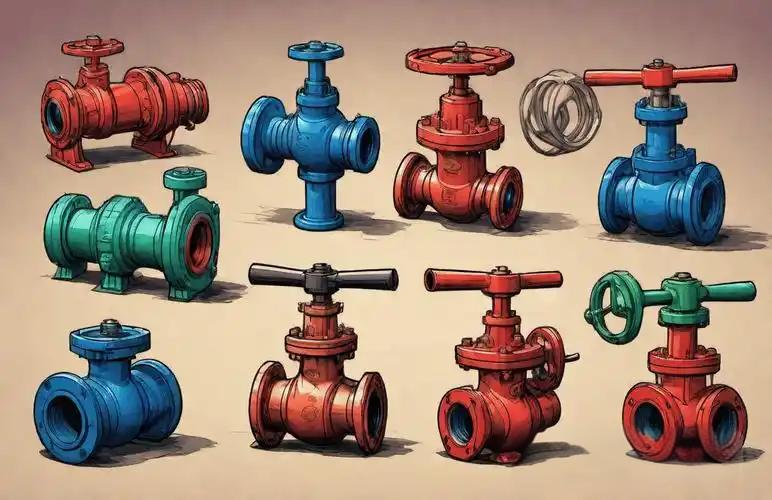

Valves play a vital role in industrial and piping systems, where they are responsible for controlling the flow of media. There are several types of valves available in the market, each with their unique advantages and disadvantages. The following is a detailed description of five common types of valves – gate valves, butterfly valves, ball valves, globe valves and plug valves – which we hope will be helpful to you.

- Gate Valves

The closing member (gate) of a gate valve moves in a vertical direction along the axis of the passageway and is mainly used to completely cut off the flow of media. Gate valves are not suitable for regulating flow.

Advantages:

Fluid resistance is small, the medium flows smoothly.

Open and close the required torque is small, easy to operate.

Applicable to the medium to two directions of flow pipe network, the flow direction is not restricted.

Fully open, the sealing surface by the working medium erosion is small.

Simple shape and structure, good manufacturing process.

Short structure length, space saving.

Disadvantages:

The external dimension and opening height are larger, requiring larger installation space.

Sealing surface relative friction in the process of opening and closing, wear and tear, high temperature is easy to abrasion.

Processing, grinding and maintenance is difficult.

Longer opening and closing time, not suitable for rapid operation. - Butterfly valve

Butterfly valve opens, closes and regulates the fluid passage by reciprocating the disc-type opening and closing parts about 90°.

Advantages:

Simple structure, small size, light weight, save material.

Quick opening and closing, low fluid resistance, suitable for rapid operation.

Can be used for media with suspended solid particles, also suitable for powdery and granular media.

Widely used in metallurgy, light industry, electric power, petrochemical and other systems of piping.

Disadvantages:

Flow rate adjustment range is limited, open 30% when the flow rate is close to 95%.

Not applicable to high temperature, high pressure piping system, the general working temperature below 300 ℃, the pressure level below PN40.

Sealing performance is relatively poor, suitable for sealing requirements are not high occasions. - ball valve

The opening and closing member of the ball valve is a sphere, which is opened and closed by rotating the sphere 90° around the axis of the valve stem. Ball valves can also be used to cut off, distribution and change the direction of media flow.

Advantages:

With the lowest flow resistance, fluid passes smoothly.

Suitable for corrosive media and low boiling point liquids, not easy to jam.

In a wide range of pressure and temperature can realize complete sealing.

Fast opening and closing, shock-free operation, suitable for automated systems.

The spherical closing member can be automatically positioned at the boundary position to ensure reliable sealing.

Compact structure and light weight, suitable for low temperature media system.

The valve body is symmetrical and can withstand the stress from the pipeline.

The closing member can withstand the high pressure difference during closing and has a long service life.

Disadvantages:

Sealing materials (e.g. PTFE) are easy to deteriorate at high temperatures, and the service temperature is limited.

Regulating performance is relatively poor, especially pneumatic or electric valves. - Globe valve

Globe valve closing member (valve flap) along the center line of the valve seat to move, the change of the valve seat orifice and the valve flap stroke is proportional to the relationship. Globe valves are suitable for cutting off, regulating and throttling.

Advantages:

Good abrasion resistance, the friction between the valve flap and the valve body sealing surface is small.

Small opening height, space saving.

Good manufacturing process, easy to maintain.

Higher temperature resistance level, suitable for steam valves.

Disadvantages:

Fluid resistance is large, affecting the efficiency of media flow.

Slow opening speed, not suitable for rapid operation. - plug valve

The closing member of the plug valve is in the shape of a plunger, and the passage port on the plug is connected or separated from the passage port on the valve body by 90° rotation.

Advantages:

Frequently operated opening and closing quickly and easily.

Fluid resistance is small, the medium flows smoothly.

Simple structure, small size, light weight, easy to maintain.

Good sealing performance, to ensure that the medium does not leak.

Installation direction is not restricted, the media flow direction can be arbitrarily selected.

No vibration, low noise, suitable for quiet environment.

Disadvantages:

The sealing surface is too large, the torque is large, the operation is not flexible enough.

Affected by its own weight, limited caliber size.

Large size valves need to use inverted plug structure, which may affect the sealing effect.

Understanding the advantages and disadvantages of these valves will help you make an informed decision when selecting a valve. Each type of valve has its applicable occasions and limitations, and it is vital that you choose the right type of valve for your specific needs.