Electric Vacuum Butterfly Valve is an advanced valve, which drives the valve stem or butterfly plate through electric actuator to realize opening and closing action. This kind of valve can precisely control the opening, closing or intermediate position of the valve through the switching of external power supply or external input signal. In vacuum systems, motorized vacuum butterfly valves are used to isolate the air flow between different sections, thus ensuring the vacuum level of the system.

Motorized vacuum butterfly valves play an important role in many industrial fields, such as semiconductor manufacturing, pharmaceutical and chemical processing, smelting, vacuum cooling, and vacuum cooking. Its excellent sealing performance and low leakage rate ensures gas quality and significantly improves productivity.

Product Features:

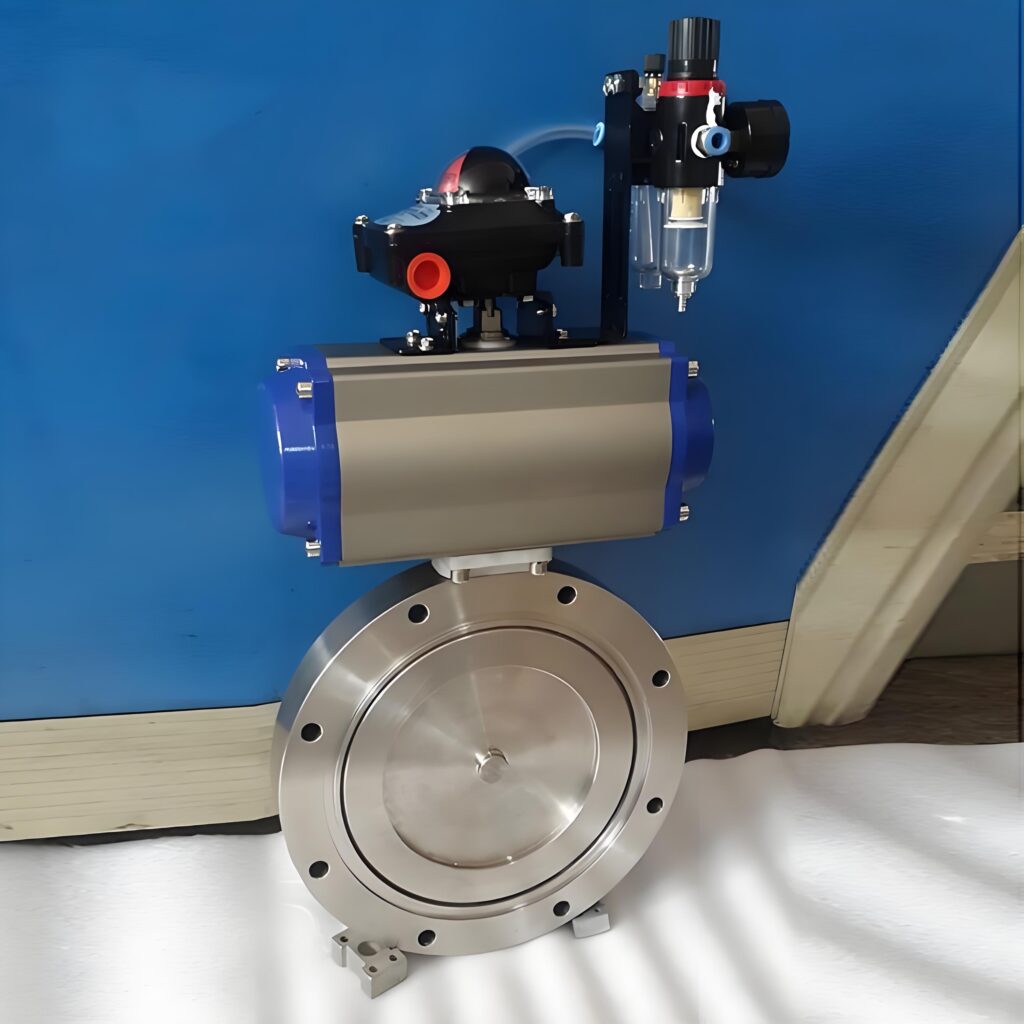

Electric Vacuum Butterfly Valve adopts a new design of centerline butterfly plate welded with short structural steel plate, which is compact, light weight and easy to install. At the same time, its small flow resistance and large flow capacity make the gas flow more smoothly. In addition, there is no connecting rod, bolt and other structures in the valve, which makes it work reliably and have a long service life, and it can be installed in multiple positions and is not affected by the direction of medium flow.

Application characteristics:

Pressure: Suitable for environments close to complete vacuum, the maximum pressure drop is usually within a few millibars or kilopascals.

Vacuum: capable of working in conditions close to absolute vacuum, suitable for environments where the pressure is much lower than atmospheric pressure.

Negative pressure tolerance: capable of withstanding a negative pressure of no more than 1 kg force/cm2 (approx. 98 kPa), i.e. a pressure slightly below atmospheric pressure.

Use of temperature range: generally applicable to the temperature range of -29 ℃ to 300 ℃, special design can be adapted to a wider range of temperatures.

Working principle and difference with common butterfly valve:

When the electric actuator is activated, it will drive the valve disk to rotate, so as to control the flow of gas. The valve disc usually adopts disc-like structure, which has good sealing and fluid control ability. By controlling the rotational speed and steering of the electric actuator, precise control of the fluid can be realized, including opening, closing or regulating.

Compared with ordinary butterfly valves, electric vacuum butterfly valves are mainly used in negative pressure environments, i.e., the pressure in the inner chamber is lower than atmospheric pressure, which is suitable for vacuum piping systems. On the other hand, ordinary butterfly valves are mainly used in positive pressure environments, where the pressure is greater than or equal to atmospheric pressure, and are not suitable for vacuum environments. In addition, vacuum butterfly valves require highly sealed connections, dense structure and gasket materials to ensure performance under vacuum conditions. The ordinary butterfly valve has no such special requirements, and is widely used in a variety of occasions where the flow of medium needs to be cut off or connected.

Precautions for use:

In order to ensure the normal operation of electric vacuum butterfly valve, the following points need to be noted:

Selection of suitable materials: according to the characteristics of the medium and the working environment, select the appropriate valve material to ensure the corrosion resistance and sealing of the valve.

Pay attention to the installation position and direction: When installing the valve, make sure that its position and direction are correct to ensure that the direction of gas flow is consistent with the design of the valve.

Regular inspection and maintenance: Regular inspection and maintenance of the valve, including checking the sealing performance, cleaning and lubrication, etc., to ensure its long-term stable operation.

In conclusion, electric vacuum butterfly valves play an important role in industry, and their efficient gas control capability and excellent sealing performance make them the preferred solution in many industrial fields.

Electric Vacuum Butterfly Valves: Efficient Gas Control Solutions for Industry

Electric Vacuum Butterfly Valves: Efficient Gas Control Solutions for Industry