Diaphragm valve is a unique globe valve, which uses the diaphragm as the opening and closing parts to close the flow path, cut off the fluid, and separate the inner cavity of the valve body from the inner cavity of the valve cover. The diaphragm of this valve is usually made of elastic, corrosion-resistant and impermeable materials such as rubber, plastic, etc., while the valve body is mostly made of plastic, fiberglass, ceramic or metal lining.

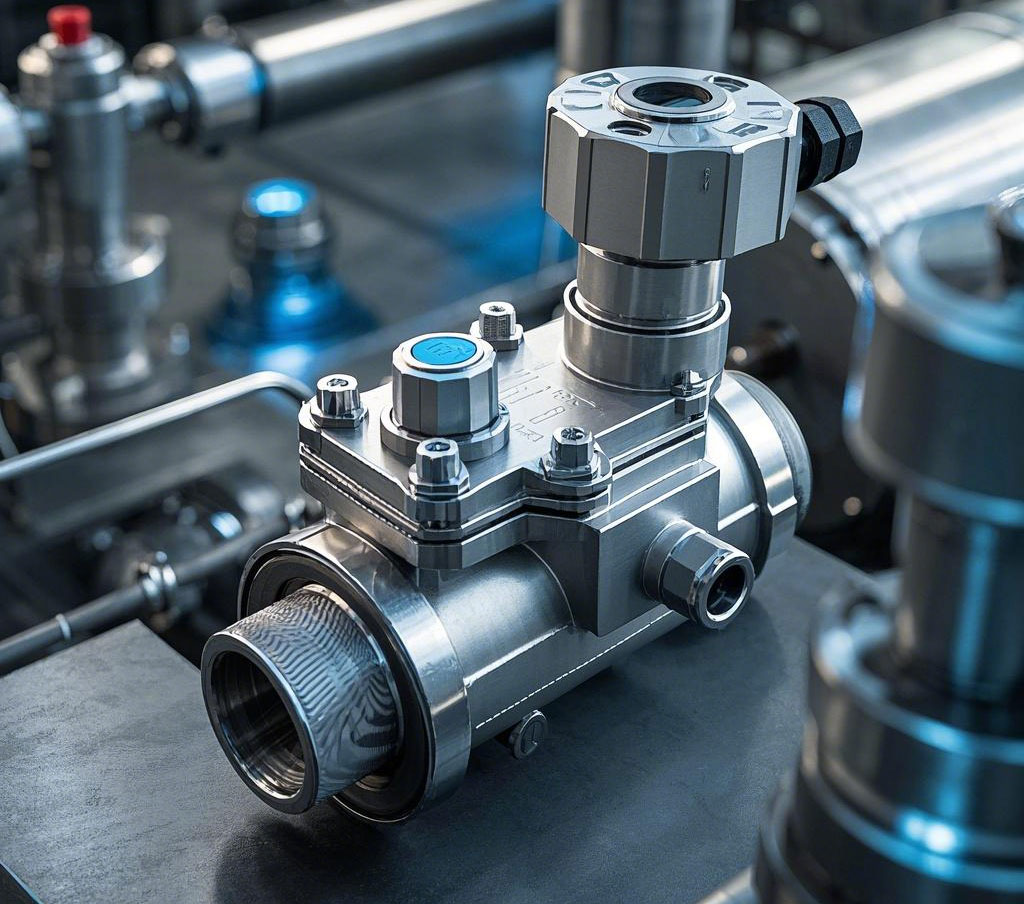

The structure of the diaphragm valve is relatively simple, but the sealing and anti-corrosion performance is very good, while the fluid resistance is also very small. Therefore, it is particularly suitable for low pressure, low temperature, strong corrosive and containing suspended substances in the medium. According to the different forms of structure, the diaphragm valve can be divided into a variety of types such as roof type, cut-off type and gate type; and according to the different ways of driving, it can be divided into manual, pneumatic and electric.

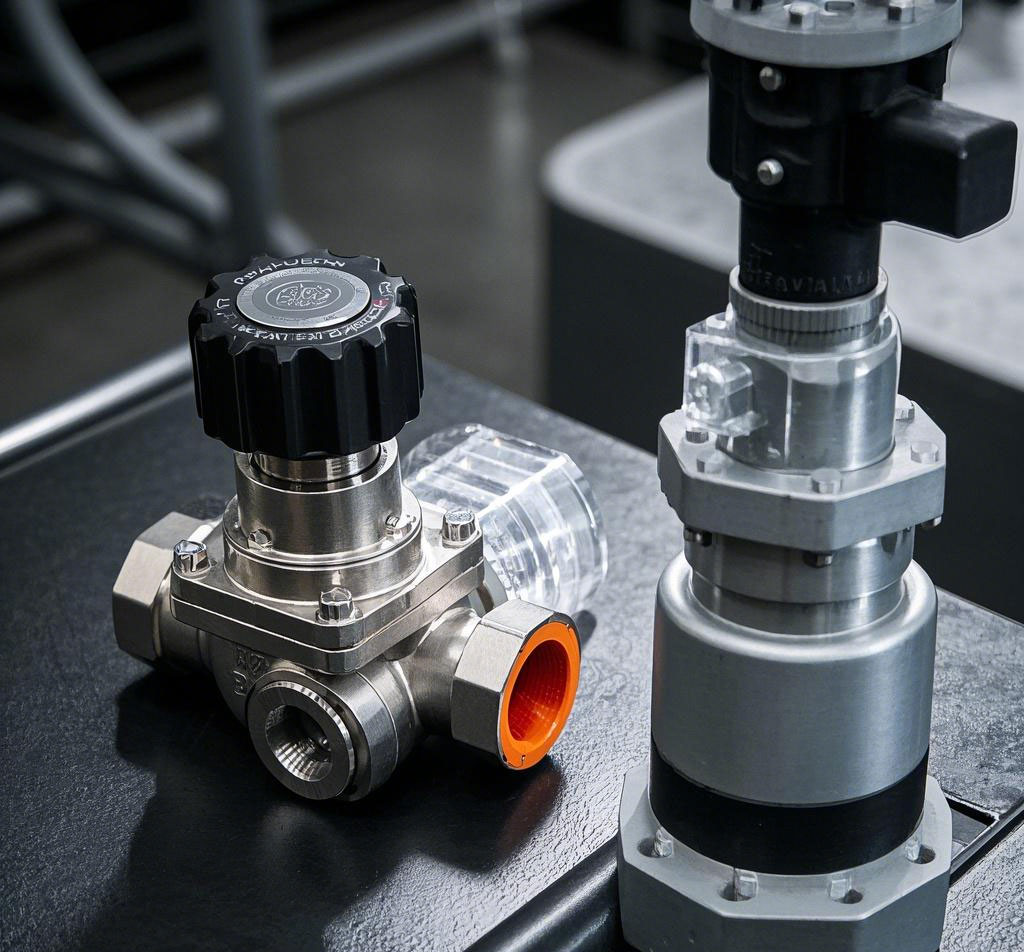

Compared with traditional valves, the structure of the diaphragm valve is significantly different. Its opening and closing parts are a piece of diaphragm made of soft material, which completely separates the inner cavity of the valve body, the inner cavity of the valve cover and the driving parts. Currently, diaphragm valves have been widely used in various fields, and common types include rubber-lined diaphragm valves, fluorine-lined diaphragm valves, unlined diaphragm valves, and plastic diaphragm valves.

Diaphragm valves contain a flexible diaphragm or combination of diaphragms with a closing member attached to the diaphragm, usually a compression device. The valve seat can be either a weir or a pipe wall that runs straight through the flow path. A significant advantage of diaphragm valves is the complete isolation of the operating mechanism from the media path, which ensures the purity of the working medium and avoids the impact of the medium in the line on the working parts of the operating mechanism. In addition, no separate seal of any kind is required at the valve stem, unless it is used as a safety feature for controlling hazardous media.

In diaphragm valves, the working medium only comes into contact with the diaphragm and the valve body. Since both the diaphragm and the valve body can be made of many different materials, these valves are ideally suited for controlling a wide range of working media, and are particularly suitable for handling media with chemically aggressive or suspended particles. However, the operating temperature of diaphragm valves is usually limited by the lining materials of the diaphragm and the valve body, which range from approximately -50°C to 175°C. The diaphragm valve can be used for a wide variety of applications.

Diaphragm valves are very simple in structure, consisting of only three main components: the valve body, the diaphragm and the head assembly. This makes the valve easy to disassemble and service quickly, and replacement of the diaphragm can be easily accomplished on site in a short period of time.