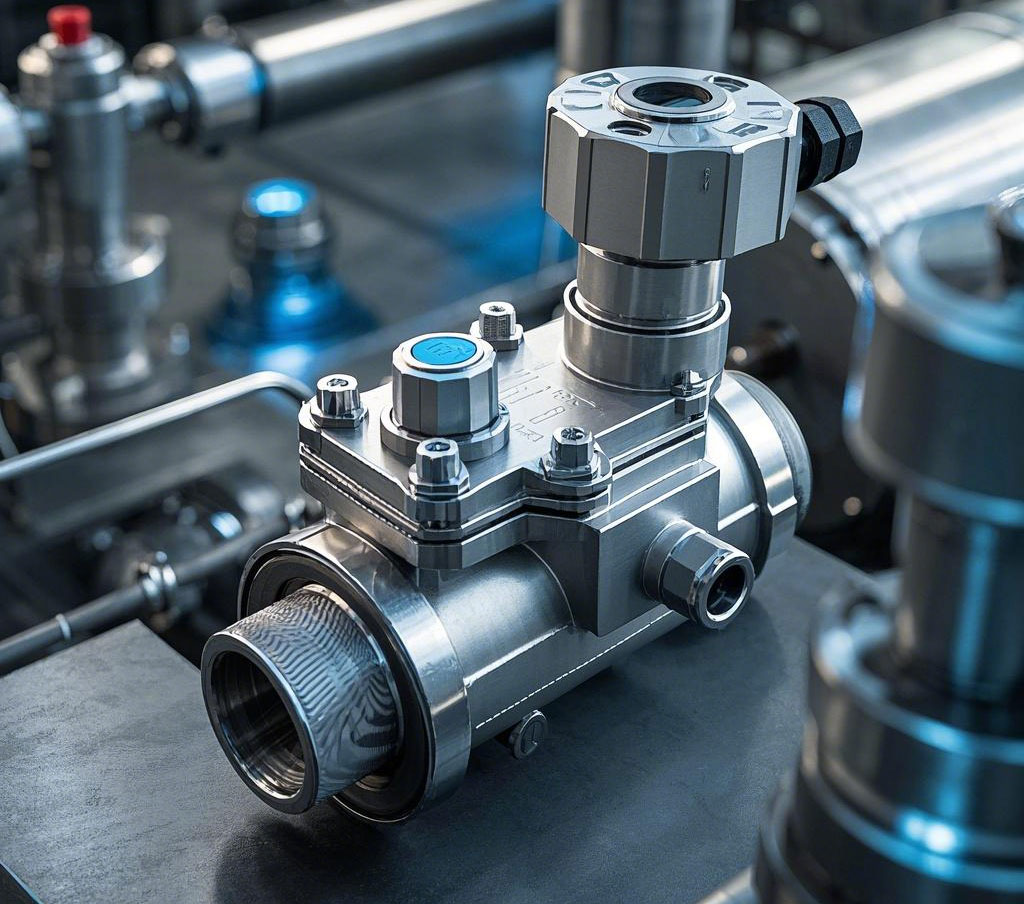

The Diaphragm Valve is an innovative fluid control valve that replaces the traditional spool assembly with a corrosion-resistant lined body and a corrosion-resistant diaphragm, which is utilized to move the diaphragm to achieve the regulating function. The design of this valve skillfully isolates the medium from the operating components, thus ensuring precise and reliable fluid control.

The body of a diaphragm valve is usually made of high-strength materials such as cast iron, cast steel, or cast stainless steel, and lined with a variety of corrosion- or abrasion-resistant materials, such as rubber and polytetrafluoroethylene. These lining materials have excellent corrosion resistance and can easily cope with the challenges of strong acids, alkalis and other strong corrosive media.

The diaphragm valve has a simple and clear structure, low fluid resistance, and a flow capacity that is superior to other types of valves of the same size. More importantly, it is capable of leak-free operation, even when handling highly viscous or suspended particles. Since the diaphragm completely isolates the medium from the stem cavity, there is no need to worry about leakage of the packing medium.

However, it should be noted that, due to the characteristics of the diaphragm and lining material limitations, diaphragm valve pressure resistance and temperature resistance is relatively limited, generally applicable to the nominal pressure of less than 1.6MPa and 150 ℃ below the temperature environment.

Diaphragm valve flow characteristics close to the fast-opening characteristics, before 60% of the stroke, the flow rate change is nearly linear; and after 60% of the stroke, the flow rate change is relatively flat. This characteristic makes diaphragm valves excellent for flow control.

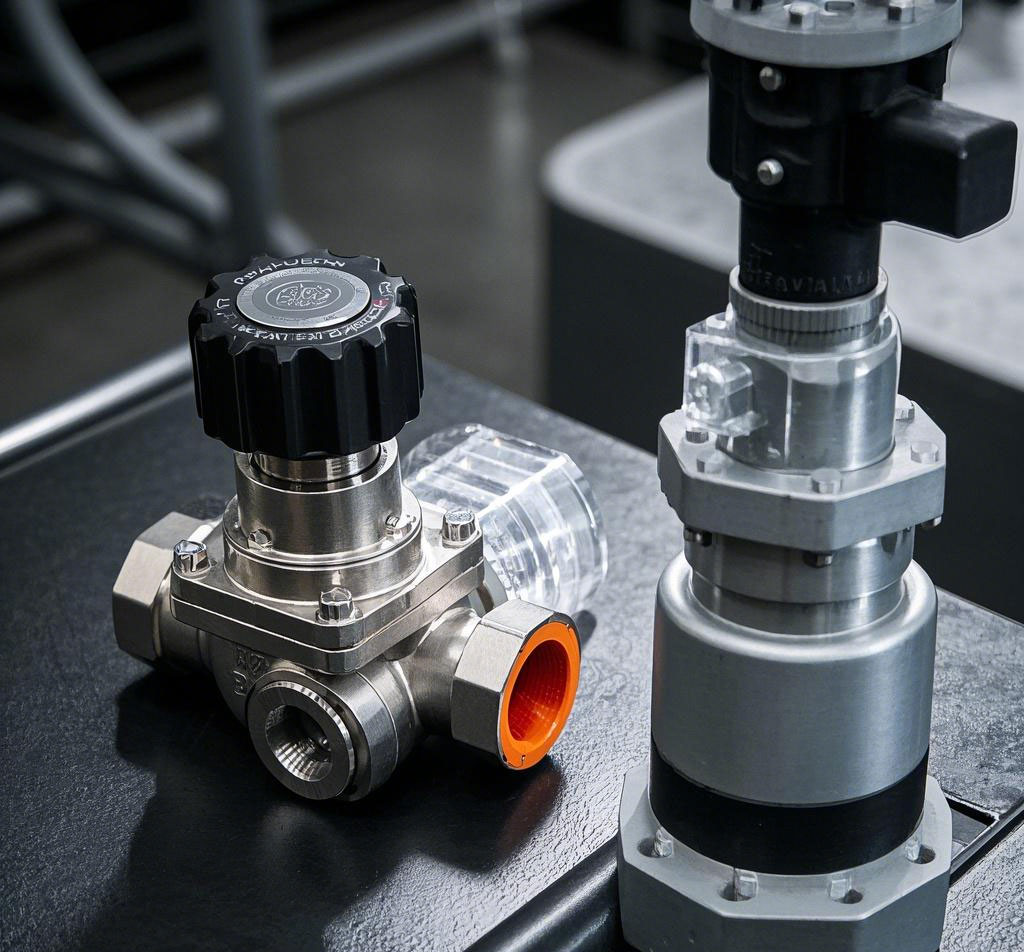

Pneumatic form of diaphragm valve can also be equipped with feedback signals, limiters and positioners and other devices to meet the needs of automation control, program control or precise regulation of flow. Among them, the feedback signal adopts advanced non-contact sensing technology to ensure the stability and reliability of the signal.

In addition, the pneumatic diaphragm valve adopts a diaphragm-type propeller cylinder, replacing the traditional piston cylinder. This design not only eliminates the drawbacks of the piston ring being easily damaged, leading to leakage and affecting the opening and closing of the valve, but also allows the valve to be manually operated through the handwheel even when the gas source fails, further enhancing its reliability and practicality.

In summary, diaphragm valves are widely used and recognized in a variety of industrial fields for their efficient, durable and flexible fluid control performance.