The sealing principle of the diaphragm valve is quite ingenious, it relies on the downward movement of the operating mechanism to press the diaphragm or diaphragm assembly tightly against the weir-type or straight-through-type lined valve body channel, so as to realize the sealing effect. The tightness of the seal, that is, the size of the sealing specific pressure, is controlled by adjusting the downward pressure of the closing member.

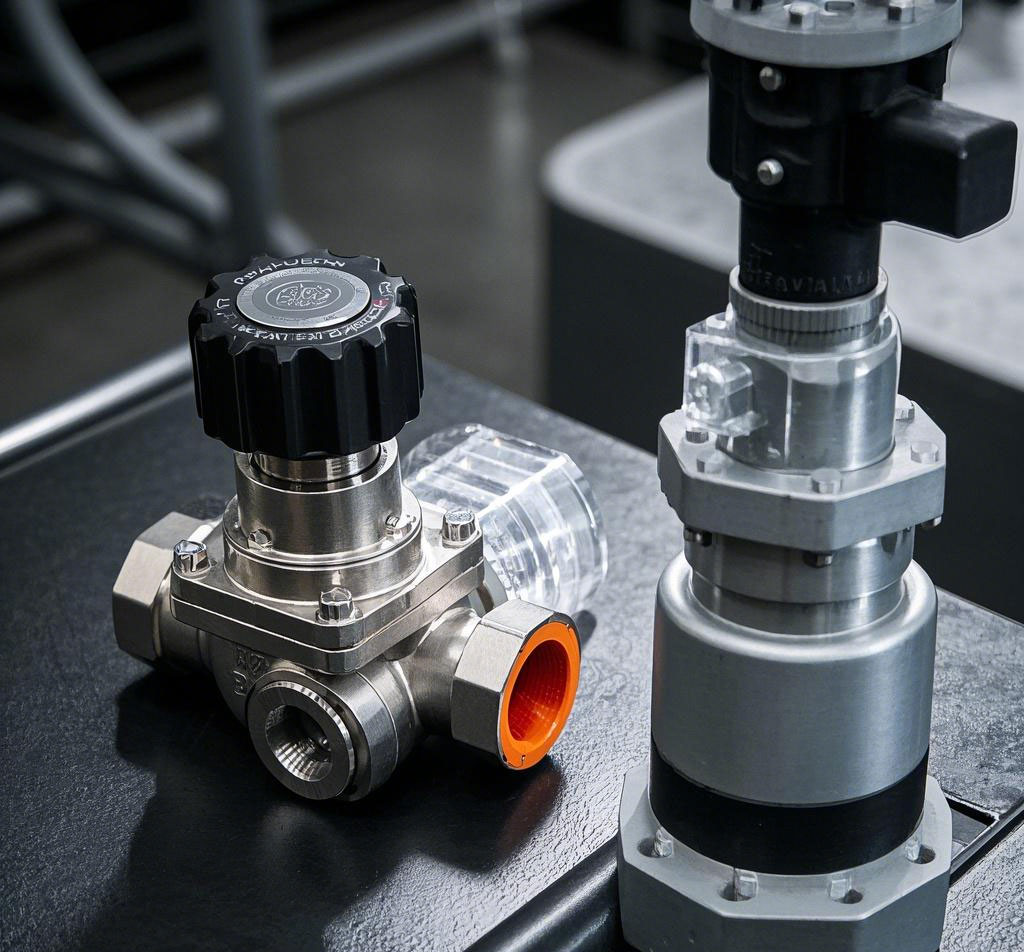

Diaphragm valves are designed with soft materials, such as rubber or PTFE, for both the body and the diaphragm. These materials are not only resistant to corrosion and abrasion, but also very flexible, so that only a small sealing force is required to achieve a perfect seal.

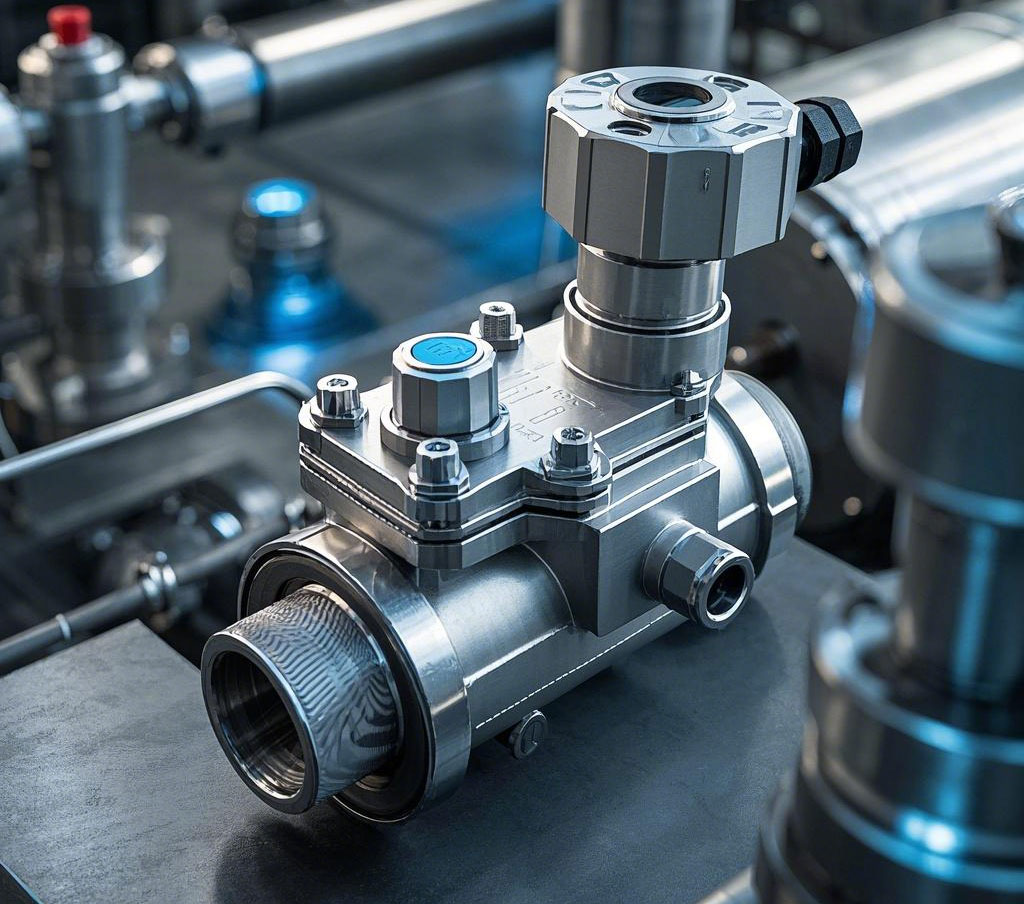

The structure of a diaphragm valve is very simple and consists of three key components: the valve body, the diaphragm and the bonnet assembly. The diaphragm plays a crucial role here, as it completely separates the lower cavity of the valve body from the upper bonnet cavity. In this way, components such as the valve stem, stem nut, valve flap and pneumatic or electric control mechanism located above the diaphragm do not come into direct contact with the medium, thus avoiding the risk of leakage. At the same time, this design also eliminates the traditional packing box sealing structure, making the diaphragm valve more simple and efficient.

Overall, with its unique sealing mechanism and simple structural design, the diaphragm valve has shown excellent performance and reliability in a variety of fluid control applications.