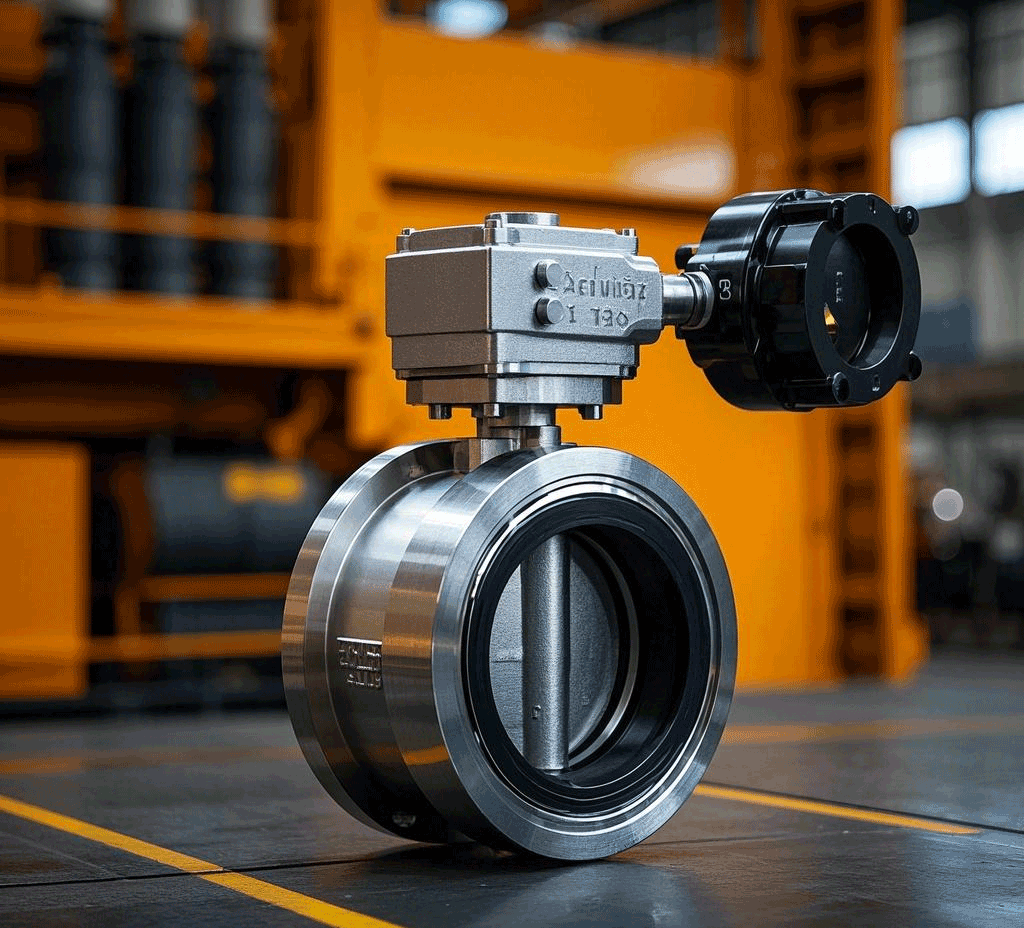

Regulating valves, also known as control valves, play a key role in industrial automation control systems. It utilizes power actuation to change process parameters such as flow, pressure, temperature and level by receiving signals from a control unit. This component usually consists of two parts: the actuator and the valve.

In terms of stroke characteristics, control valves can be categorized into two main types: straight stroke and angle stroke. And according to the type of power used in its actuator, it can be divided into three types: pneumatic control valves, electric control valves and hydraulic control valves. In addition, according to the function and characteristics of the control valve, they can also be divided into three types of linear characteristics, equal percentage characteristics and parabolic characteristics.

The application range of control valves is very wide, it can handle a variety of fluid media including air, water, steam, a variety of corrosive media, slurry and oil. For the industrial field, this flexible and multi-functional equipment is undoubtedly an important tool for automated process control.