Ball valves, the right hand in the field of fluid control, with its unique structure and function, unique in many valves. Today, we will have an in-depth understanding of several major types of ball valves and their characteristics, to help you better choose and use this fluid control “rotary master”.

Classification of ball valves

According to the structure of the form:

Floating ball valve: this ball valve ball is floating, it can produce displacement under the action of medium pressure, tightly pressed on the sealing surface of the outlet end, to ensure the sealing effect. Floating ball valve structure is simple, good sealing, but it should be noted that the load borne by the ball will be fully transmitted to the outlet seal. Therefore, when selecting, make sure that the sealing ring material can withstand the working load. This structure is usually used in low and medium pressure environments.

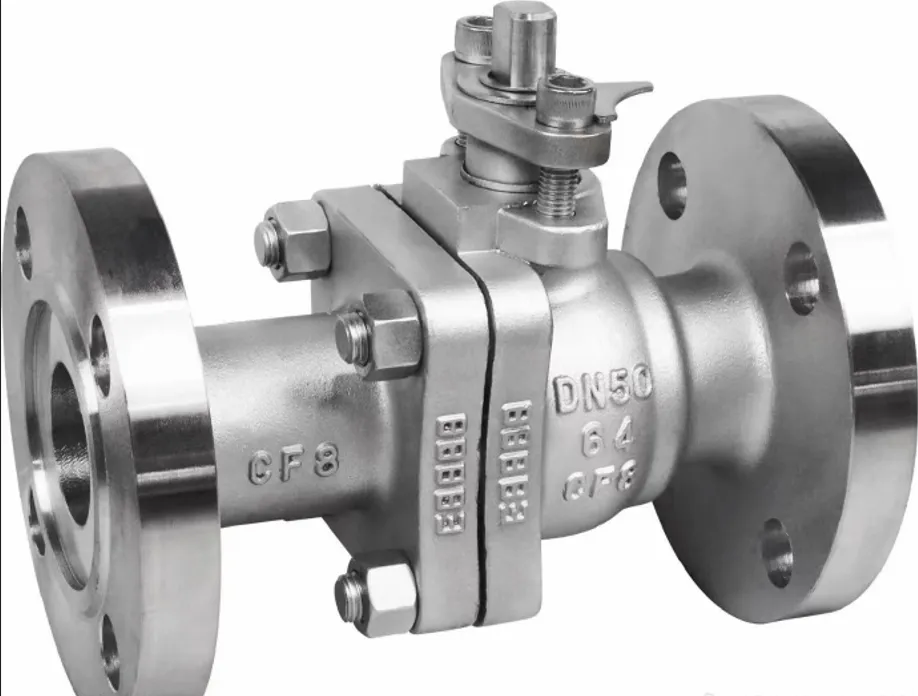

Fixed Ball Valves: Unlike floating ball valves, the ball of a fixed ball valve is fixed and will not move due to pressure. It has a floating seat, when the medium pressure, the seat will move, so that the seal ring tightly pressed on the ball to ensure sealing. Fixed ball valves are usually equipped with bearings and have low operating torque, making them ideal for high pressure and large diameter valves. In order to further enhance the sealing and reduce the operating torque, in recent years there are also oil-sealed ball valves, that is, between the sealing surfaces injected with special lubricant to form an oil film.

Resilient Ball Valve (Orbital Ball Valve): The ball of this type of ball valve is resilient and made of metal, with a high sealing specific pressure, which requires the application of an external force in order to achieve the sealing effect. The design of the resilient groove allows the ball to rise open and press against the seat when closing, and to loosen and return to its original shape before turning, reducing friction and operating torque. Resilient ball valve is especially suitable for high temperature and high pressure media.

V type ball valve: V type ball valve belongs to a fixed ball valve, with a single seat sealing structure, excellent regulating performance, flow characteristics for equal percentage, adjustable ratio of up to 100:1. its V-shaped notch and the metal valve seat has a shear effect between the valve seat, is very suitable for dealing with the media containing fibers, tiny solid particles, slurry and so on.

According to the channel points:

Straight-through ball valve: fluid passes through the valve directly, without turning.

Angle ball valve: fluid in the valve turn through.

Three-way ball valve: divided into T-type and L-type. T-type can be connected to three orthogonal pipelines to achieve diversion and merging; L-type can only be connected to two orthogonal pipelines, play a distribution role.

According to the connection method:

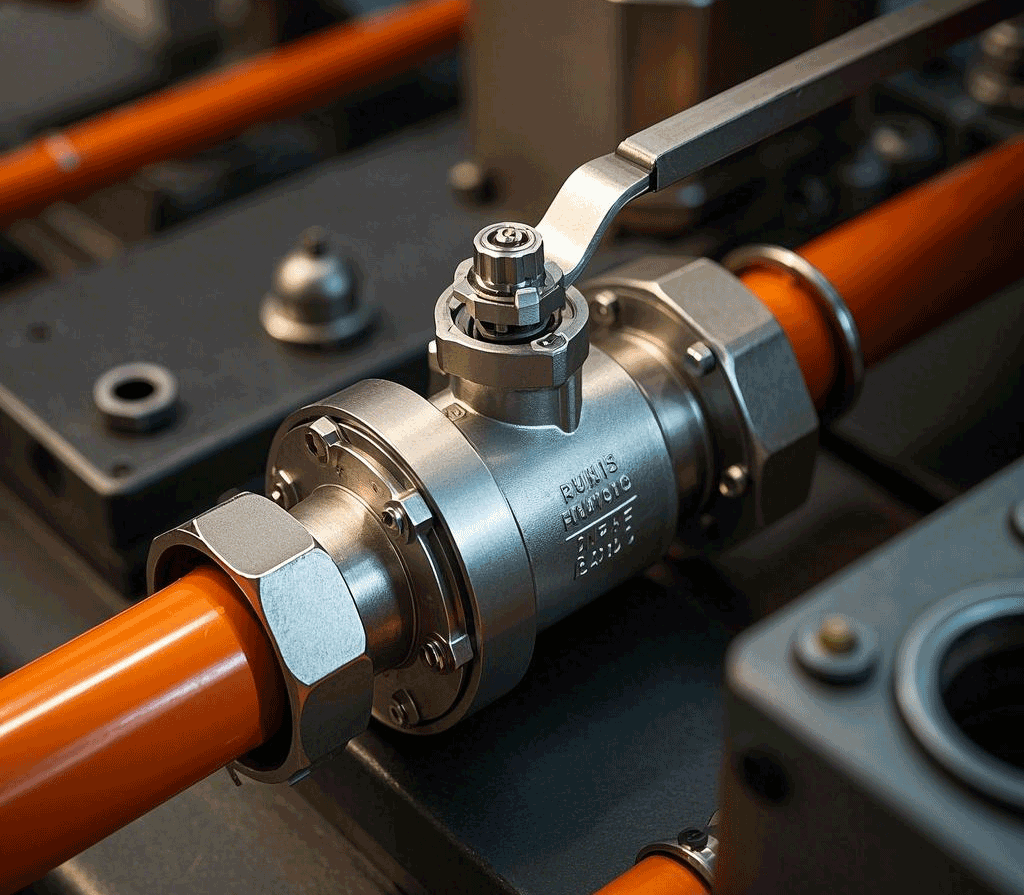

Threaded connection ball valve: through the thread and pipeline connection.

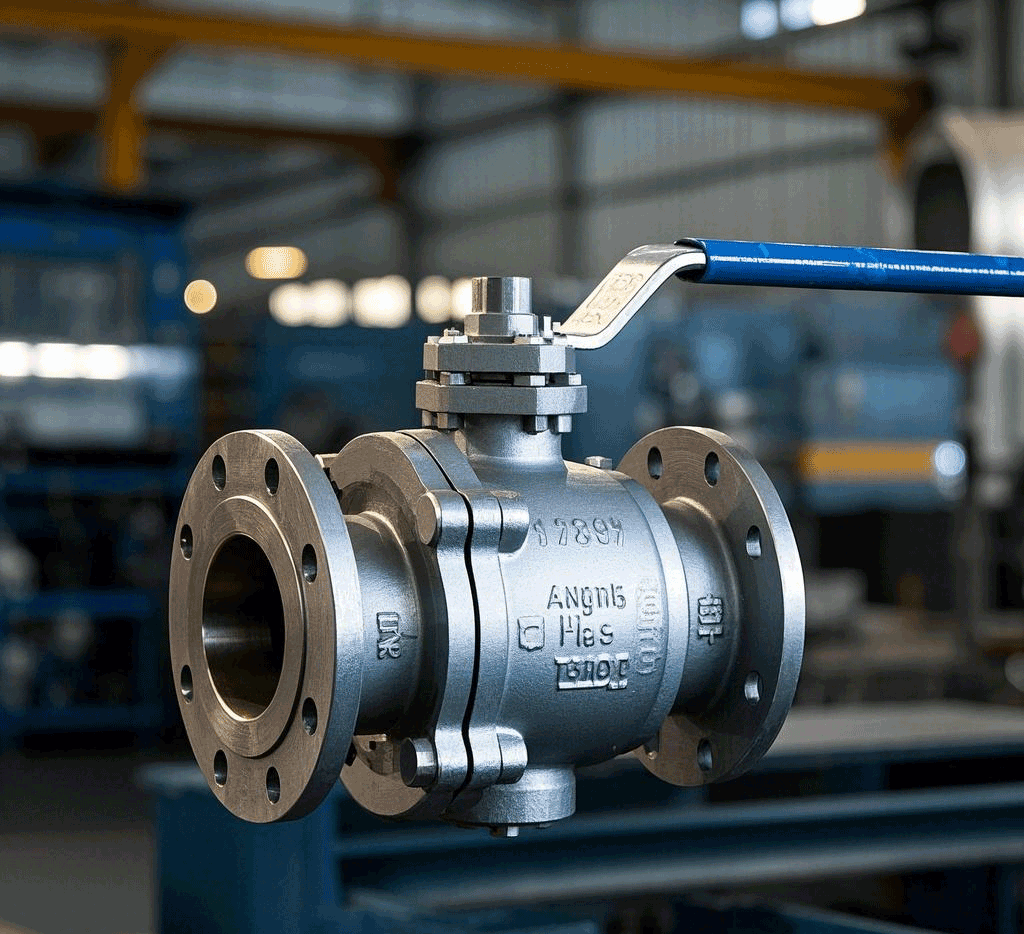

Flange connection ball valve: through the flange and pipeline connection, suitable for large valves.

Welded ball valve: connected to the pipeline through welding, commonly used in high-pressure environment.

Conclusion

There are many types of ball valves, and each type has its unique characteristics and applicable scenarios. When choosing ball valves, please select the most suitable type of ball valve according to your specific needs and working environment, taking into account factors such as pressure, temperature, media type and ease of operation. We hope this article can help you better understand ball valves and provide strong support for your fluid control projects.