A check valve, also often called a check valve or a backstop valve, is an automatic valve that plays a vital role in industrial fluid systems. Its main function is to prevent the medium from flowing backwards, to avoid reversal of the pump and drive motor, and to ensure that the medium in the container is not accidentally released. For example, the bottom valve installed at the bottom of the pump suction pipe is a kind of check valve.

The working principle of the check valve is quite ingenious: its opening and closing parts can rely on the flow of the media to open or close the force itself. When the normal flow of media, the valve opens, allowing the fluid to pass; and when the medium tries to flow backwards, the valve is quickly closed to prevent the reverse flow of fluid. This automatic control features make the check valve in the one-way flow of media on the pipeline has been widely used, thus effectively preventing the occurrence of potential accidents.

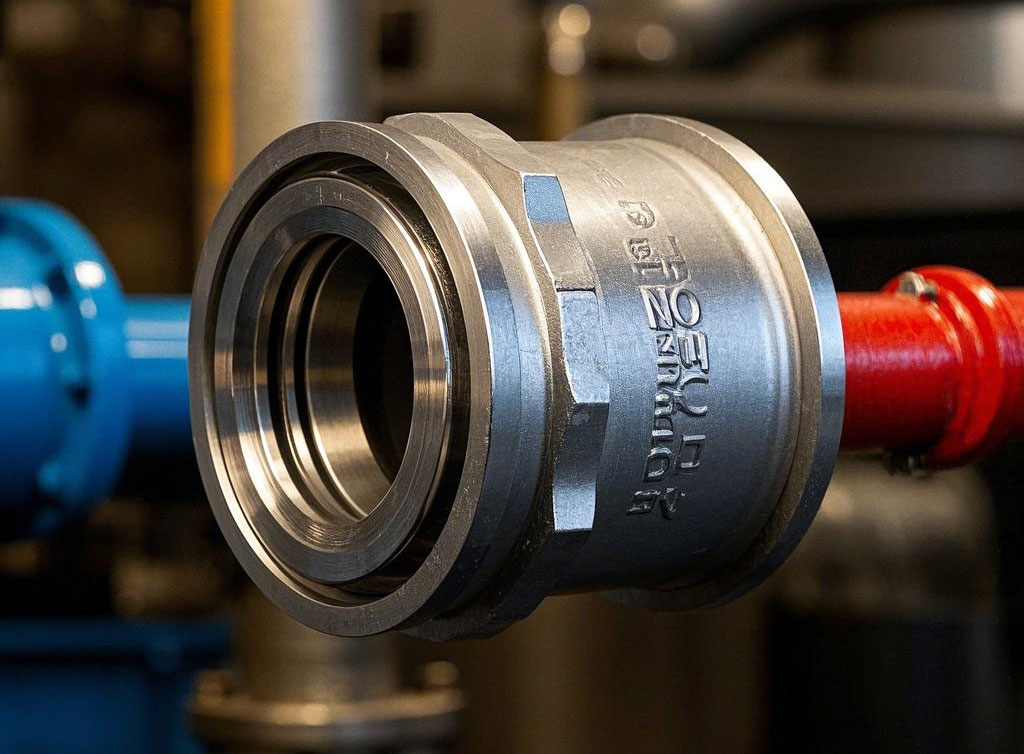

From the structural point of view, check valves are mainly divided into three types: lift type, swing type and butterfly type. Lift check valves can be categorized into vertical and horizontal according to the different installation methods. Swing check valves are divided into single-valve, double-valve and multi-valve according to the number of flaps. Butterfly check valves are usually of straight-through design. These different types of check valves in the connection form also makes a difference, mainly including threaded connection, flange connection, welding and clamped connection.

In general, the check valve is like a loyal guard in the fluid system, it silently guards the one-way flow of media to ensure the safe and stable operation of the entire system. Whether it is at the bottom of the pump suction pipe, or in other occasions that need to prevent backflow of media, check valves play an indispensable role.