In industry and everyday life, fluid flow control is critical. In order to ensure that the fluid flows in the established direction and to prevent problems caused by backflow, check valves, the “gatekeeper” of the automatic valve industry, play an indispensable role.

Check valves, also known as check valves or check valves, are valves that work automatically without manual operation. Its core mission is to prevent the medium (fluid) backflow, to protect the pump and its drive motor from reverse damage, and to prevent accidental release of medium in the container. Imagine the bottom of the pump suction pipe, the silent work of the bottom valve, it is also a member of the check valve family.

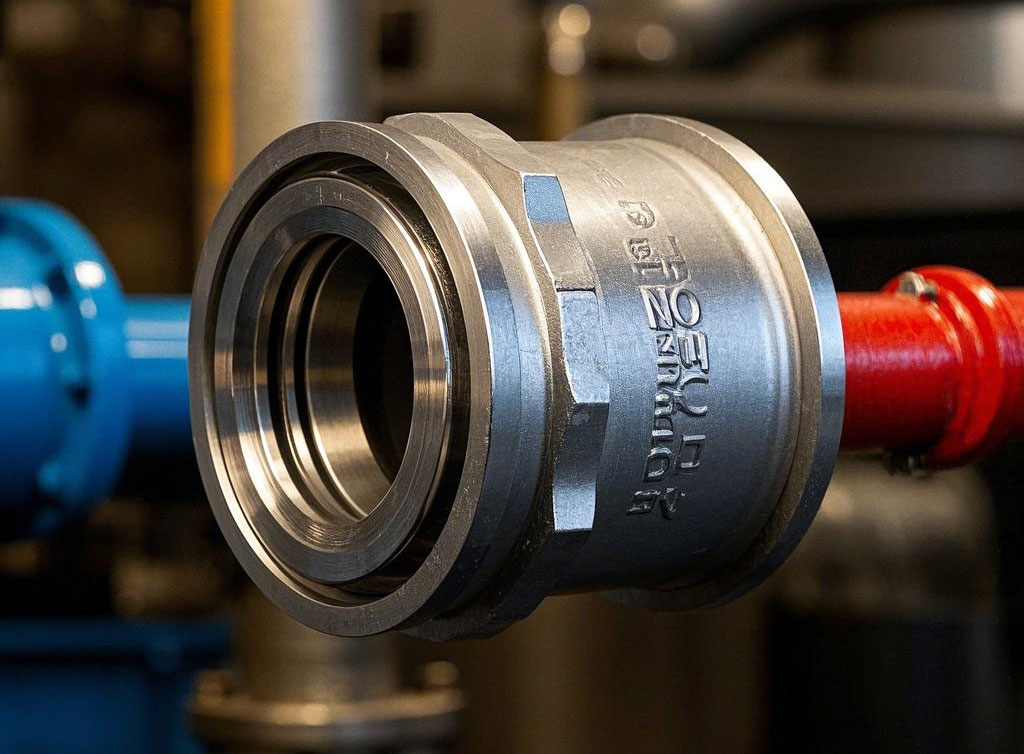

The working principle of the check valve is quite ingenious: its opening and closing parts (i.e., the key components of the valve) can open or close by itself with the force of the media flow. When the medium flows smoothly, the opening and closing parts will be pushed open, allowing the fluid to pass smoothly; and when the medium tries to flow backwards, the opening and closing parts will automatically close to prevent the occurrence of backflow. This automatic control characteristics, make the check valve become the ideal choice for one-way flow of media pipeline.

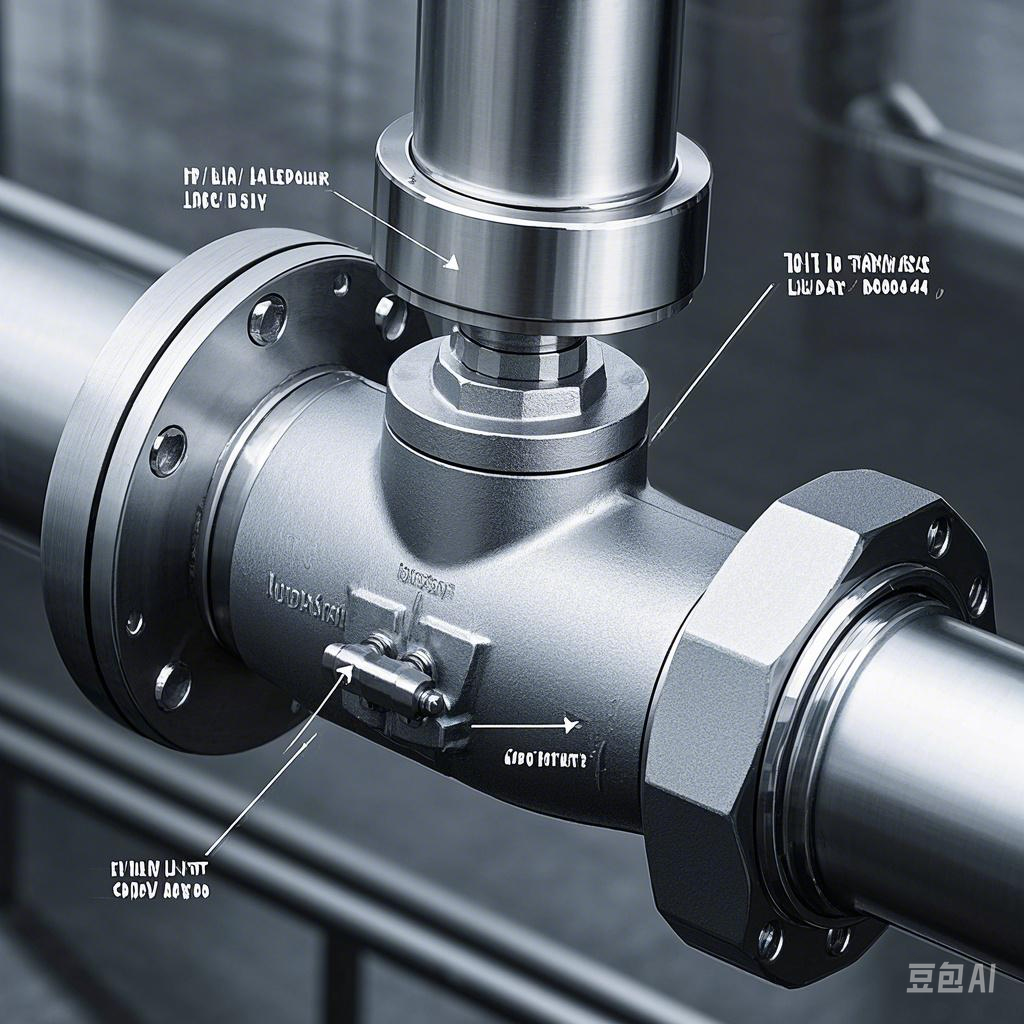

In terms of structure, check valves are mainly divided into three main categories: lift type, swing type and butterfly type. Lift check valves are divided into vertical and horizontal, and they control the passage of fluid through the lifting action. Rotary check valve is divided into single-valve type, double-valve type and multi-valve type, and its opening and closing parts rotate like a door to open or close. Butterfly check valves, on the other hand, have a straight-through design and a more compact structure.

In addition to the structural differences, check valves also provide a variety of options in the connection method. Whether threaded, flanged, welded or clamped connections, they can meet the needs of different piping systems. This enables check valves to be widely used in a variety of industrial fields, such as petroleum, chemical industry, water treatment, food processing and so on.