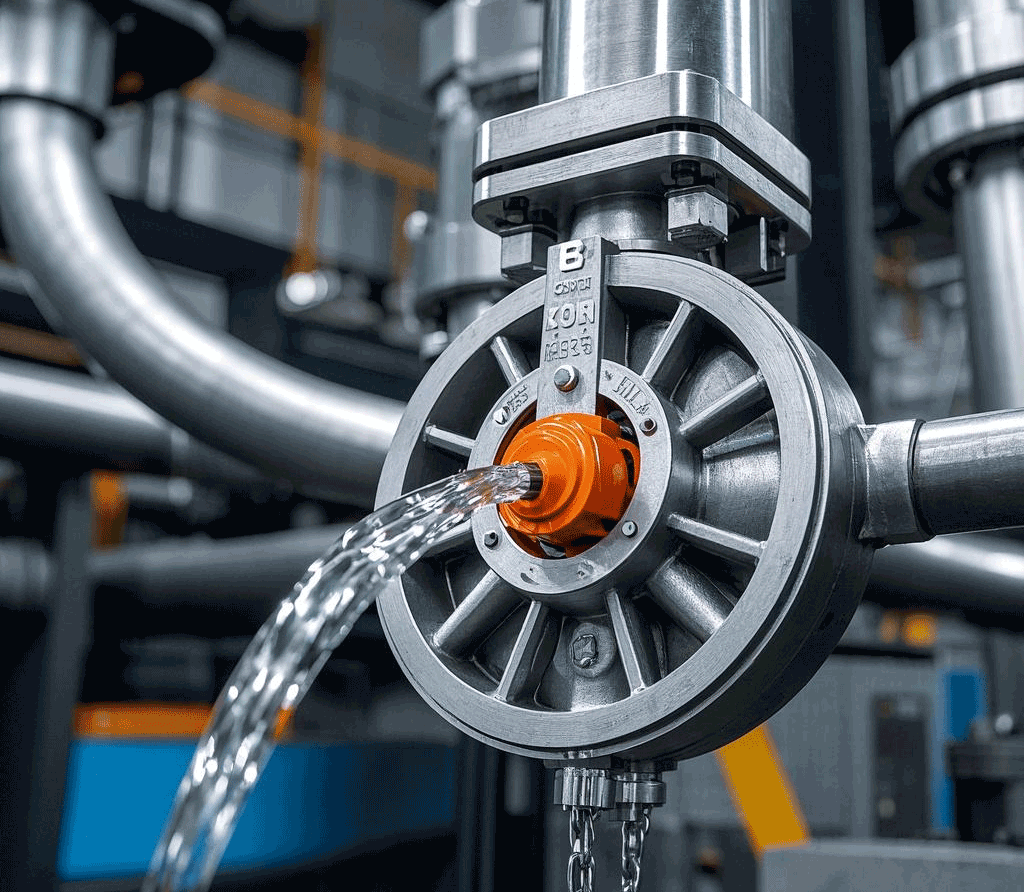

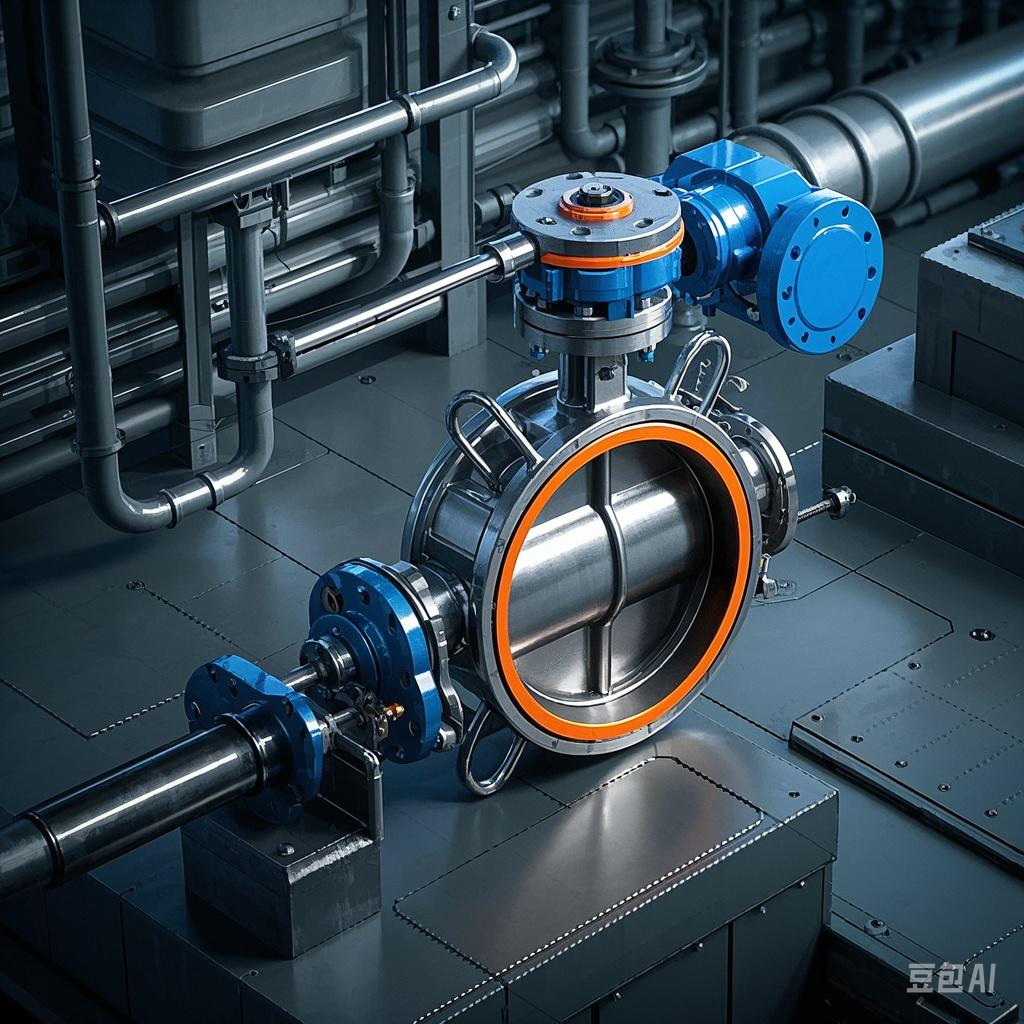

A butterfly valve is an ingeniously designed valve that opens, closes or regulates the passage of fluid by means of a circular butterfly plate that acts as an opening and closing member as the valve stem rotates. Imagine the butterfly plate as a revolving door in the pipeline, which is installed in the direction of the diameter of the pipeline and can be opened or closed like a door.

Inside the butterfly valve, there is a cylindrical channel in which the butterfly plate rotates around its axis. It rotates from 0° to 90°. When the butterfly plate rotates to the 90° position, the valve is in a completely open state and the fluid can pass freely.

Due to its unique design and superior performance, butterfly valve has been widely used in several engineering systems. Whether it is gas transportation system such as furnace, coal gas, natural gas, liquefied petroleum gas, city gas, or fluid pipeline in the field of hot and cold air, chemical smelting, power generation and environmental protection, butterfly valve can play an excellent regulating role. It can be used to accurately control the flow of fluids, but also as a switch to cut off the flow of media.

What’s more, butterfly valve is very suitable for pipelines conveying various corrosive or non-corrosive fluid media. This means that butterfly valves provide reliable performance whether they are handling highly corrosive chemical solutions or conveying clean natural gas.

Overall, butterfly valves are an important product in the field of fluid control because of their flexibility and applicability. No matter where in the U.S. you need to precisely control the flow of fluids, butterfly valves are a trusted choice.

Butterfly Valves: The Flexible Choice for Fluid Control