Butterfly valves, the star product in the field of fluid control, with its unique design concept and excellent performance, have been widely used and rapidly developed in the global industrial field, especially in industrial powerhouses such as the United States, Japan, Germany, France and Italy.

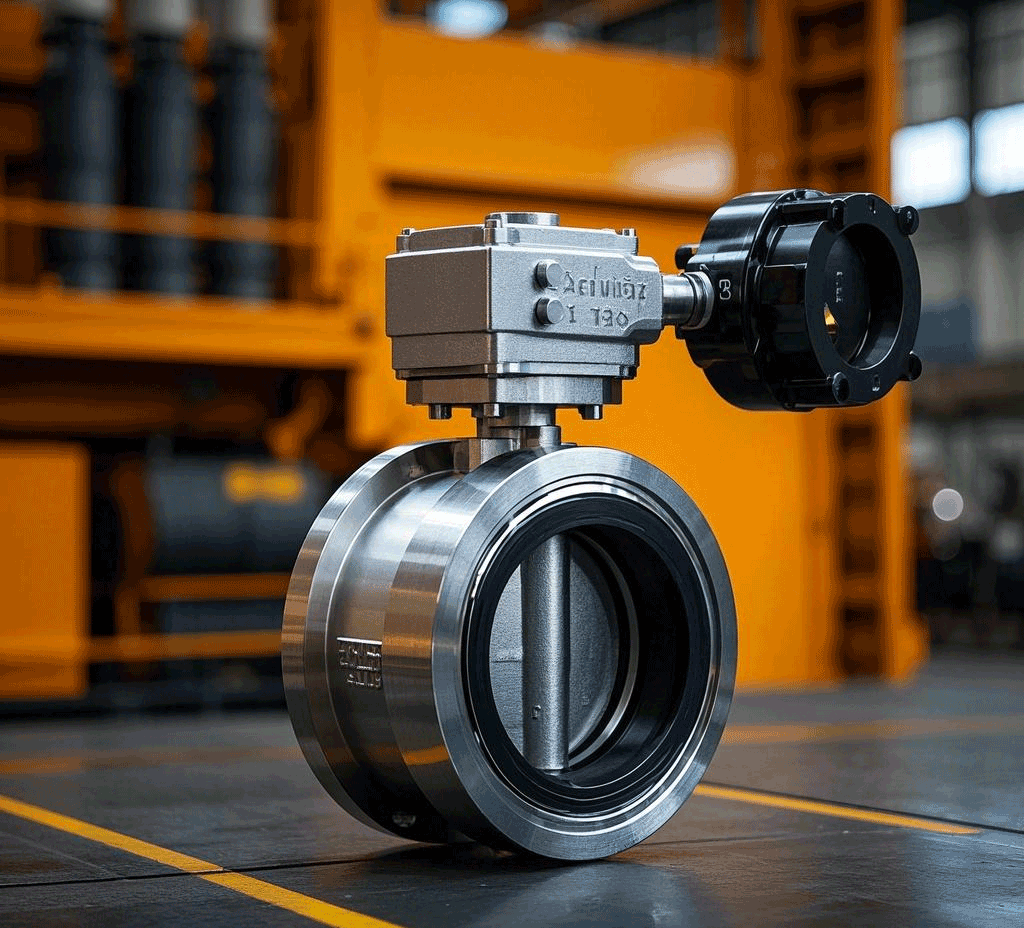

The working principle of a butterfly valve is quite intuitive: it opens, closes or regulates a fluid passage by rotating a disc-type opening and closing member (which we call the valve plate) by about 90 degrees. This design not only makes the butterfly valve simple, compact, and lightweight, it also saves a lot of material and makes installation easier. What’s more, the butterfly valve has a small driving torque, which makes it easy and quick to operate, and at the same time, it also has good flow regulation and excellent closing sealing.

At first, butterfly valve is just a simple baffle valve, the closing effect is not very tight, and it is often used as a flow adjustment valve and damping valve in water pipeline system. However, with the continuous progress of technology, especially the application of chemical-resistant synthetic rubber on butterfly valves, the performance of butterfly valves has been significantly improved. Synthetic rubber is widely used in the manufacture of butterfly valve linings and resilient seats to meet the needs of various complex working conditions due to its corrosion resistance, erosion resistance, dimensional stability, good resilience, easy molding and low cost.

In addition, the application of polymer polymeric materials such as polytetrafluoroethylene (PTFE) and its filler-modified materials further enhances the performance of butterfly valves. These materials are extremely corrosion resistant and stable, not easy to age, have a low coefficient of friction, and are easy to mold and maintain dimensional stability. By filling and adding appropriate materials, butterfly valve sealing materials with higher strength and lower coefficient of friction can be obtained, thus overcoming certain limitations of synthetic rubber.

In order to meet the demands of industrial applications such as high and low temperatures, strong erosion, and long life, metal-sealed butterfly valves have been developed. These butterfly valves are made of high-strength alloy materials that are resistant to high temperature, low temperature, strong corrosion and strong erosion, which enables metal-sealed butterfly valves to maintain excellent performance even under extreme working conditions. Today, we can already see butterfly valves with large diameters (up to 9,750 mm), high pressures (up to 2.2 kN/cm2), and a wide range of temperatures (-102 to 606 degrees Celsius), which have reached an unprecedented level of technology.

The wide application of computer-aided design (CAD) and computer-aided manufacturing (CAM) as well as flexible manufacturing system (FMS) in the valve industry has revolutionized the design and manufacturing of butterfly valves. These technologies not only revolutionize the valve design and calculation methods, reduce the repetitive workload of professional and technical personnel, but also enable them to have more energy to devote to the improvement of product performance and the development of new products. Especially in the field of metal-sealed butterfly valves, the application of CAD/CAM makes the design of three-dimensional sealing vice a reality, which will not cause any extrusion, abrasion or wear to the sealing surface in the process of opening and closing, thus greatly improving the sealing and service life of butterfly valves.

The butterfly valve has a small flow resistance when fully open, and sensitive flow control when open between about 15 degrees and 70 degrees. Therefore, in the field of large-diameter regulation, butterfly valves are very commonly used and are expected to gradually become the dominant valve type. In addition, because the movement of the butterfly valve plate is wiping, so most butterfly valves can be used for media with suspended solid particles, and according to the strength of the seal can also be used for powdery and granular media.

Classification of Butterfly Valves

There are many types of butterfly valves, and there are many different ways to categorize them. The following are some common classification methods:

Classification by structural form:

Center sealed butterfly valve

Single eccentric seal butterfly valve

Double eccentric seal butterfly valve

Three eccentric seal butterfly valve

Classified according to the sealing surface material:

Soft seal butterfly valve: sealing side by non-metallic soft materials or metal hard materials and non-metallic soft materials.

Metal hard seal butterfly valve: sealing side by metal hard material.

Classified by sealing form:

Forced seal butterfly valve: including elastic seal butterfly valve (sealing pressure is generated by the valve plate extrusion valve seat when the valve is closed) and external torque seal butterfly valve (sealing pressure is generated by the torque added to the valve shaft).

Pressurized sealing butterfly valve: the sealing pressure is generated by the elastic sealing element on the valve seat or valve plate.

Automatic sealing butterfly valve: sealing pressure is generated automatically by the medium pressure.

Classified according to the working pressure:

Vacuum butterfly valve: working pressure is lower than standard atmospheric pressure.

Low-pressure, medium-pressure, high-pressure and ultra-high-pressure butterfly valve: categorized according to the different nominal pressure.

Classification according to working temperature:

High, medium, normal, low and ultra-low temperature butterfly valves: categorized according to the different operating temperatures.

Classified according to the connection mode:

Clamped butterfly valve

Flanged butterfly valve

Lug Butterfly Valve

Welded butterfly valve

Butterfly valve sealing principle

The sealing principle of butterfly valve is relatively simple: the valve plate ensures that the sealing surface has a suitable surface roughness value during processing, while the synthetic rubber seat also forms a suitable surface roughness value during molding. When the valve is closed, the sealing surface of the valve plate extrudes the synthetic rubber seat, which produces elastic deformation and forms elastic force as the sealing pressure, thus ensuring the sealing performance of the valve.

In summary, butterfly valves play an increasingly important role in the global industrial field with their high efficiency, flexibility and excellent performance. With the continuous progress and innovation of technology, the application prospect of butterfly valve will be more broad.