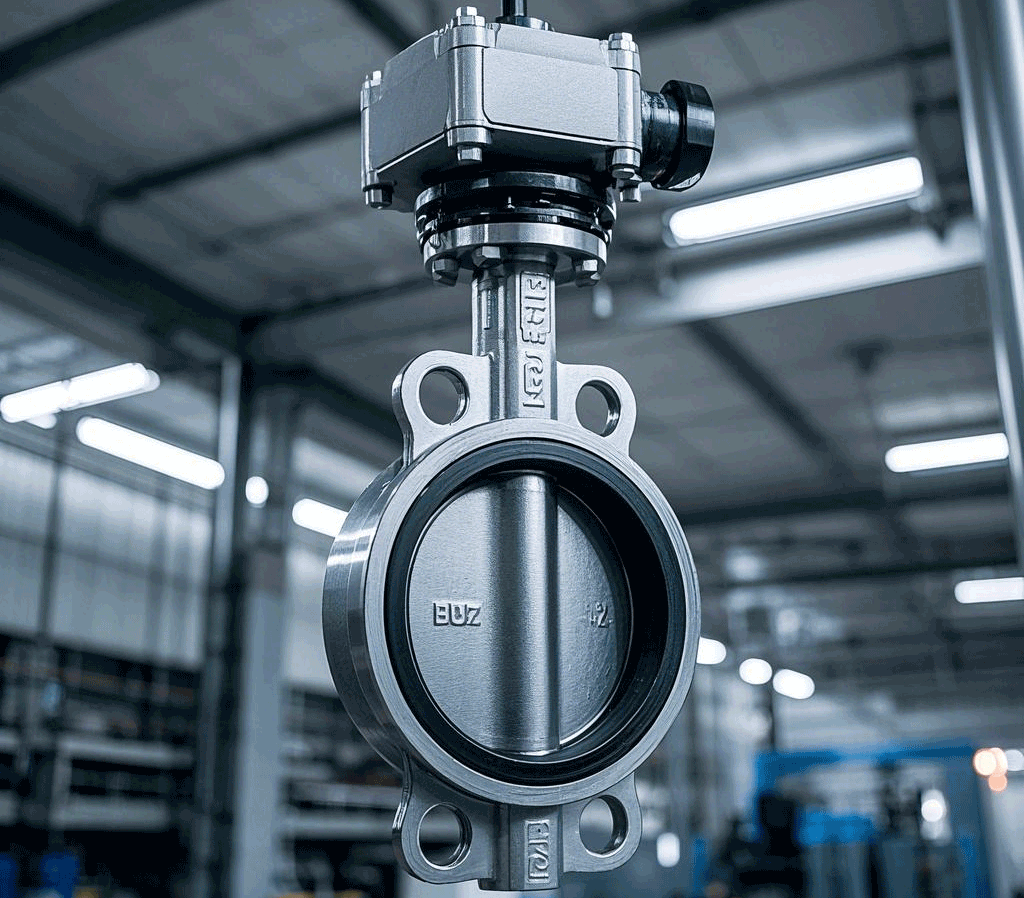

Butterfly valve is a kind of valve used to control the opening, closing and regulating of the fluid passage. Its core component is a circular butterfly plate which rotates with the valve stem. The butterfly plate is installed in the diameter direction of the pipeline and rotates around the axis within the cylindrical channel of the valve body. When the butterfly plate is rotated to 90°, the valve is fully open.

Construction and Installation Guidelines

Position and direction: The installation position, height, and inlet/outlet direction of the butterfly valve must be in strict accordance with the design requirements, and the connecting parts need to be ensured to be firm and tight.

Handle direction: If the butterfly valve is installed on the heat preservation pipeline, its handle must keep upward direction for easy operation.

Inspection and testing: Before installing the butterfly valve, its appearance must be inspected. The nameplate of the valve should comply with the national standard GB 12220 “General Valve Marking”. For the working pressure of more than 1.0 MPa or in the main pipeline to play a cut-off role in the valve, the installation of the strength and tightness of the performance of the test should also be carried out to ensure that qualified before use. Strength test pressure for the nominal pressure of 1.5 times the duration of not less than 5 minutes, the valve shell and packing should be no leakage. The pressure of the tightness test is 1.1 times the nominal pressure, and the test time and standard should be in accordance with the requirements of GB 50243 to ensure that there is no leakage on the sealing surface of the valve.

Product selection points

Size: When choosing butterfly valves, you need to consider its size to ensure that it matches with your fluid control system.

Simple structure: Butterfly valve is a single-plate air valve with simple structure, easy processing, low cost and easy operation. However, due to its relatively low adjustment precision, it is more suitable for switching or coarse adjustment in ventilation and air-conditioning systems.

Operation mode: Butterfly valve can be operated manually, electrically or zipper type, and can be fixed at any angle within 90° to meet different control needs.

Withstand force limitation: Since the butterfly valve adopts single-axis single-plate design, its withstand force is limited. Under conditions of large differential pressure and high flow rate, the service life of the valve may be shortened. In addition, butterfly valves are also divided into closed type and common type, as well as insulated and non-insulated to meet different application scenarios.

Motorized control: motorized butterfly valves usually have only two-position control, and their motorized actuators are similar to those of multi-leaf valves, which can realize remote or automated control.

In summary, butterfly valves, as a key component of fluid control, need to be selected and installed with careful consideration of their characteristics and application scenarios to ensure that they are able to perform at their best.