The story of the butterfly valve began in the United States in the 1930s, then it spread to Japan in the 1950s, and by the 1960s it was widely used in Japan. In China, on the other hand, the popularity of butterfly valves came after the 1970s. Today, globally, butterfly valves with a diameter of more than 300 millimeters (DN300) have gradually taken the place of gate valves.

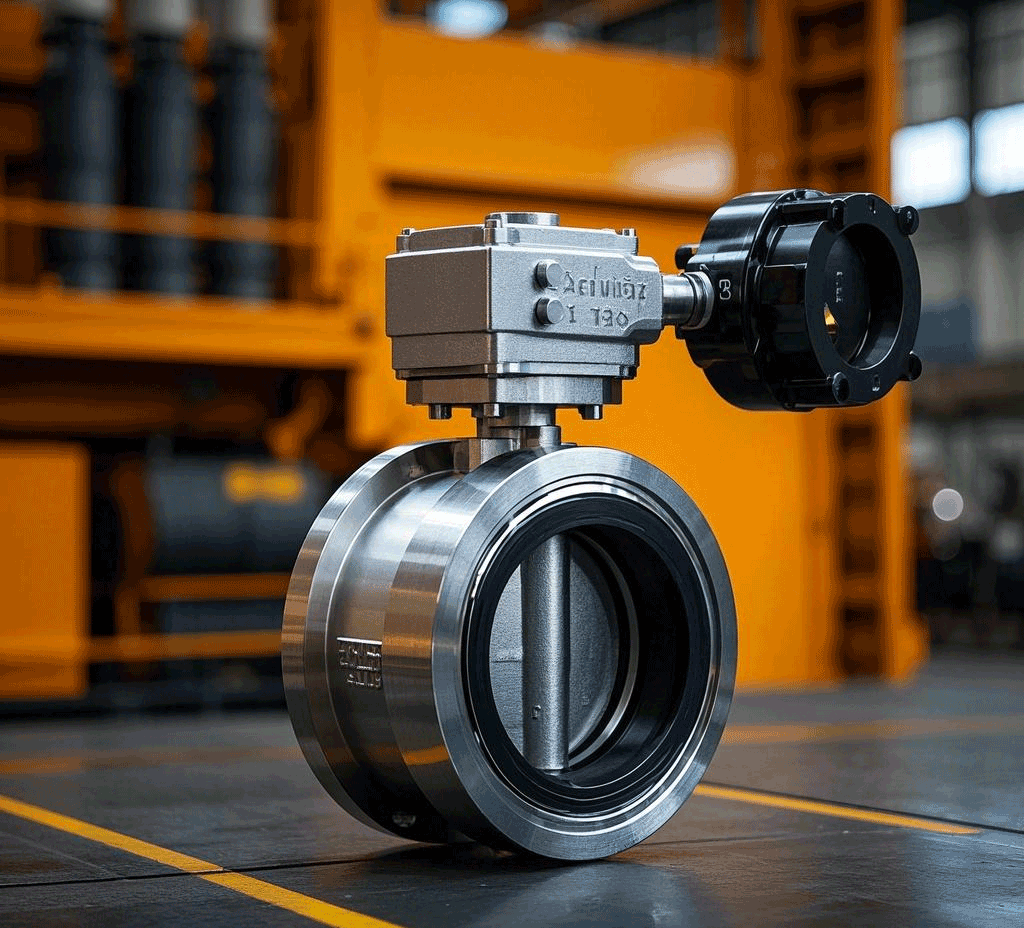

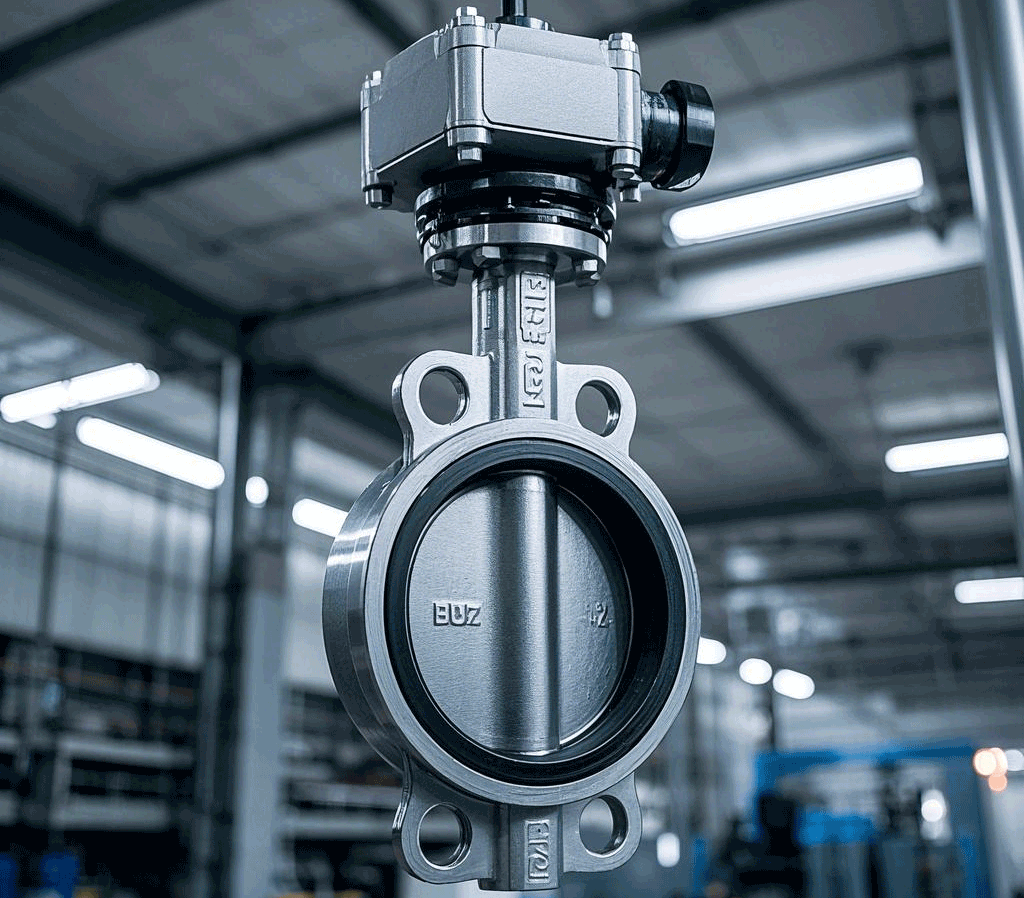

Compared to gate valves, butterfly valves have many advantages. It has a shorter opening and closing time and requires less torque to operate, which means it can be opened or closed more easily. In addition, butterfly valves require less space for installation and are lighter in weight. For example, for a valve with a diameter of 1,000 mm (DN1000), a butterfly valve weighs about 2 tons, while a gate valve weighs 3.5 tons. Butterfly valves are also easy to use in combination with a variety of actuators, providing excellent durability and reliability.

However, rubber-sealed butterfly valves, when used as throttles, can suffer from cavitation if not used properly, resulting in spalling or damage to the rubber seat. To solve this problem, metal-sealed butterfly valves have been developed internationally, which have a much smaller cavitation zone. In recent years, China has also successfully developed metal-sealed butterfly valves. In Japan, comb-shaped butterfly valves that are resistant to cavitation, low vibration and low noise have also been introduced in recent years.

Generally, the life of the sealing seat varies according to the usage. Rubber sealing seats usually last between 15 and 20 years, while metal sealing seats can last 80 to 90 years. However, the specific choice of sealing seat needs to be decided according to the specific working conditions.

The relationship between the opening of a butterfly valve and the flow rate is roughly linearly proportional. If it is used to control flow, then its flow characteristics are also closely related to the flow resistance of the pipeline. For example, if the valve caliber and form of two pipelines are identical, but the loss coefficients of the pipelines are different, then the difference in the flow rate of the valve can be very large.

When the valve is in a state with a large throttling amplitude, the back of the valve plate is prone to cavitation, which may damage the valve. Therefore, it is generally recommended that butterfly valves be used at openings other than 15°.

When the butterfly valve is in the middle opening, the shape of the opening formed by the valve body and the front of the butterfly plate will be centered on the valve spindle, and the two sides will show completely different states. On one side, the front of the butterfly plate moves in the direction of water flow, while on the other side, it moves against the direction of water flow. As a result, one side of the valve body and plate will form a nozzle-like opening, while the other side will resemble a throttling orifice. The flow rate on the nozzle side will be much faster than on the throttling side, and negative pressure may build up under the valve on the throttling side, which often causes the rubber seals to come off.

The operating torque of a butterfly valve varies depending on the opening and the direction in which the valve opens and closes. For horizontal butterfly valves, especially large-diameter valves, due to the effect of water depth, the torque generated by the difference between the head above and below the valve shaft should not be ignored. In addition, if the inlet side of the valve is equipped with an elbow, it will form a bias flow, thus increasing the moment. When the valve is in the middle opening, due to the water flow moment, the operating mechanism needs self-locking function to maintain stability.

Butterfly valve history, characteristics and applications