Performance Characteristics

(1) Regulating range: This refers to the range of ability of a pressure reducing valve to regulate its output pressure P2, and within this range, it must achieve a specific accuracy. This range depends mainly on the hardness of the regulating spring.

(2) Pressure Characteristics: When the flow rate is maintained at a certain level, if the input pressure fluctuates, the output pressure will also change, and this characteristic is the pressure characteristic. We want the output pressure to fluctuate as little as possible so that the pressure reducing valve performs better. Usually, only when the output pressure is lower than a fixed value of the input pressure, the output pressure is basically unaffected by the change of the input pressure.

(3) Flow characteristics: In the case of a constant input pressure, the output pressure will vary with the output flow. When the flow rate changes, we want the change in output pressure to be as small as possible. Generally speaking, the lower the output pressure, the smaller the change with the output flow.

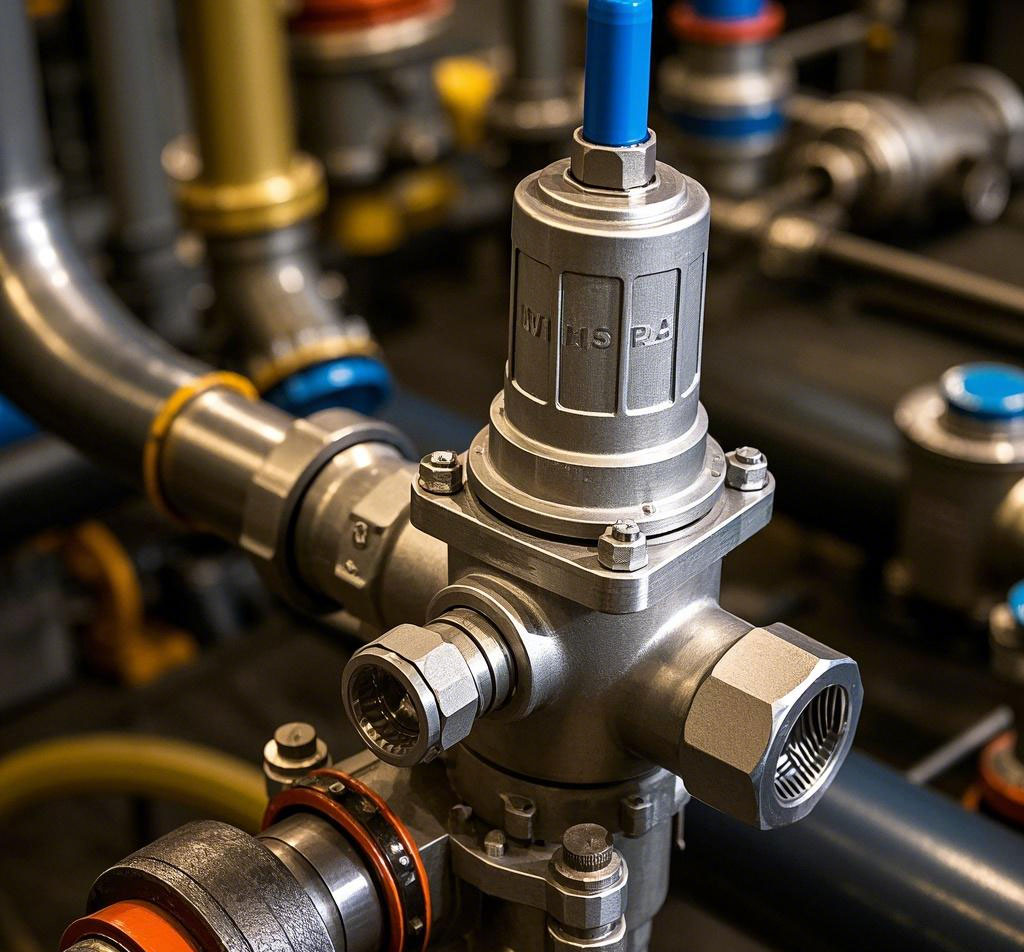

The function of a pressure reducing valve is to reduce the high pressure liquid upstream of the pipeline to the desired pressure level downstream. This type of device is mainly used where water is the transmission medium. Pressure reducing valves are widely used in high-rise buildings, areas of the city where water pressure is too high, and in mines to ensure that the proper water pressure and flow rate is available to all water points in the water supply system. Considering that the degree of water leakage and wastage is almost directly proportional to the water pressure in the water supply system, pressure reducing valves not only improve the operation of the system, but also have the potential to save water, which, according to statistics, can be up to about 30%.

Installation and adjustment steps

First close the gate valve in front of the pressure reducing valve, then open the gate valve behind the pressure reducing valve to create a low pressure environment downstream.

Turn the adjustment screw counterclockwise to the uppermost position (this represents the relatively lowest outlet pressure) and then close the gate valve behind the pressure reducing valve.

Slowly open the gate valve in front of the pressure reducing valve until it is fully open.

Slowly turn the adjusting screw clockwise to adjust the outlet pressure to the desired level (as indicated by the pressure gauge behind the pressure reducing valve). When adjustment is complete, lock the nut and open the gate valve behind the pressure reducing valve.

If the outlet pressure is higher than the set value during adjustment, it is necessary to restart the adjustment from the first step, i.e., adjustment can only be made from low to high pressure.

Principle of operation

Principle of operation: The pressure reducing valve creates local resistance to water flow through its internal flow path, thus reducing water pressure. The range of water pressure reduction is automatically adjusted by the difference between the inlet and outlet water pressure on both sides of the membrane or piston connected to the valve. The principle of fixed ratio pressure reduction is to use the floating piston water pressure ratio in the valve body for control, the inlet and outlet end of the pressure reduction ratio is inversely proportional to the area ratio of the inlet and outlet side of the piston. This pressure reducing valve runs smoothly without vibration; there is no spring in the valve body, so there is no need to worry about spring corrosion or metal fatigue failure; the sealing performance is good, no leakage, so it can reduce both the dynamic pressure (when the water flows) and static pressure (when the flow rate is zero). In particular, it does not affect the water flow while reducing pressure.

Working principle: pressure reducing valve regulates the flow of medium by controlling the opening and closing of the opening and closing parts in the valve body, so as to reduce the pressure of the medium. At the same time, it is with the help of the pressure after the valve to adjust the opening degree of the opening and closing parts, so that the pressure after the valve to maintain within a certain range. In addition, it can also be sprayed in the valve body or after the valve cooling water to reduce the temperature of the medium. This kind of valve is called pressure reducing and temperature reducing valve. Pressure reducing valves are characterized by their ability to maintain the outlet pressure and temperature within a certain range in the presence of changing inlet pressure.

Advantages

Although there is some head loss when water flows through a pressure reducing valve, it is still energy efficient overall because it reduces water waste, rationalizes system flow distribution, and improves system layout and operation. Where the medium is steam, it is best to choose a pilot operated piston type pressure reducing valve or a pilot operated bellows type pressure reducing valve. In order to facilitate operation, adjustment and maintenance, pressure reducing valves should normally be installed on horizontal piping.