Ball valve as the core component of pipeline system, its sealing performance and smooth operation directly affect the production safety. This paper analyzes the sealing principle of ball valves, and provides a systematic investigation method of holding faults.

First, the ball valve sealing principle

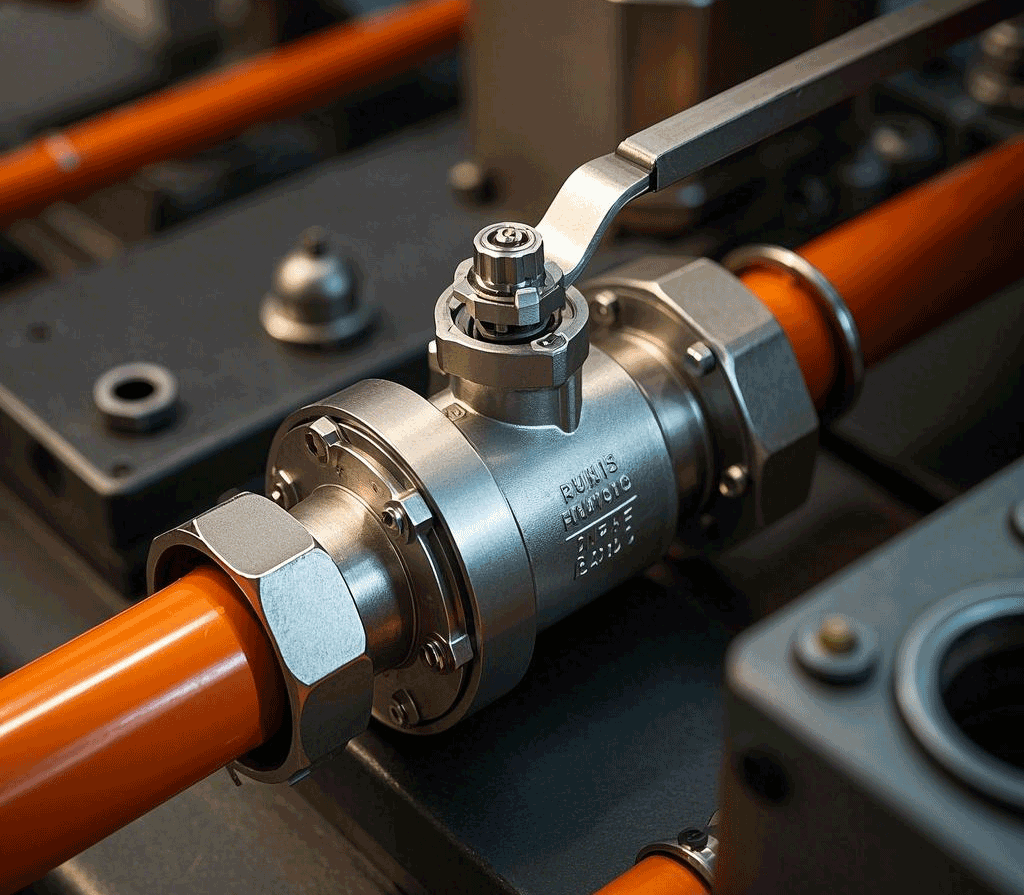

Ball valve through the ball rotation to realize the medium on and off, its sealing relies on ** double piston effect (DPE) ** design:

Sealing structure:

Seat sealing ring and the ball close fit to form a soft seal.

Medium pressure pushes the sealing ring to the ball direction of compression, to enhance the sealing.

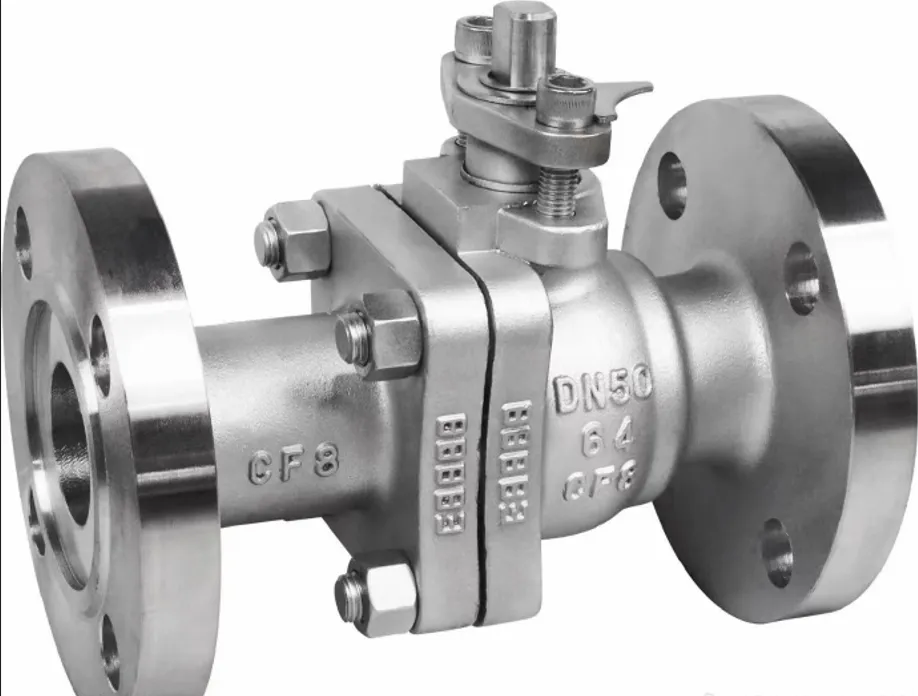

DPE Working Mechanism:

Upstream pressure forces the sealing ring to press against the ball, and downstream pressure synchronizes the sealing aid.

Realize two-way no leakage, especially suitable for gas pipeline.

Second, hold fault diagnosis process

Step 1: Transmission system inspection

Inspection content: Gearbox corrosion, bearing damage or foreign object jamming.

Treatment: disassemble and clean, replace damaged parts.

Step 2: Seal seat jamming judgment

Phenomenon: Air pressure in the valve chamber when discharging.

Reason: Hardening of sealing grease / impurities stuck / spring failure.

Verification method: Inject cleaning solution and observe whether operation is resumed.

Step 3: Excessive differential pressure judgment

Phenomenon: There is no air pressure in the valve cavity and the operating torque is abnormally high.

Principle: Differential pressure between the valve cavity and the trunk line causes the seal ring to overpressure the ball.

Troubleshooting Methods

- Transmission system failure

Preventive measures: disassemble the gearbox every year, clean and replenish grease.

Maintenance: Replace the corroded bearings and make sure the transmission parts are not jammed. - Seal seat jamming

Cleaning process:

Inject the special cleaning liquid to soak (time is adjusted according to the grease injection).

Discharge the impurities through the sewage outlet.

Maintenance: If cleaning is ineffective, disassemble the valve to replace the sealing components. - Differential pressure is too large

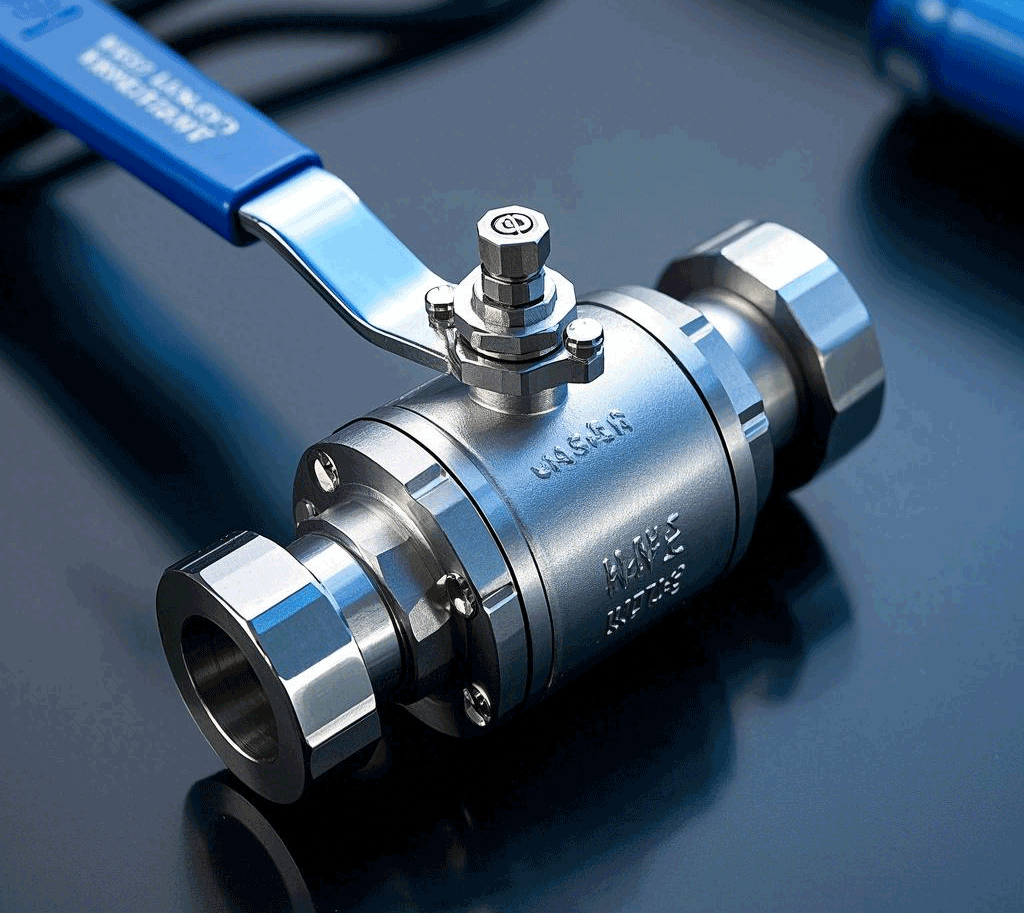

Flat pressure operation:

Use the homemade air injection device shown in Fig. 3.1 to connect the discharge nozzle and balance the pressure between the valve chamber and the trunk line.

Successful cases: Dagang station 12 “ball valve and other troubleshooting.

Risk warning of brutal operation

Forced operation of the ball valve may lead to:

Equipment damage: gear box rupture, ball scratches (triggering internal leakage).

Safety hazards: breakage of the lever or multiple operators leading to injuries.

V. Preventive Maintenance Recommendations

Sewage system upgrade:

Adopt a two-valve manifold design (Figure 4.1) to improve maintenance safety and reduce the risk of ice blockage.

Regular grease maintenance:

Inject fresh grease to prevent sealing grease from hardening.

Move the valve 10°-15° per week (when it cannot be fully opened/closed).

Drive train maintenance:

Quarterly inspection of gearbox lubrication status and cleaning of sewage foreign matter.

Sewage log analysis:

Monitor natural gas gas and optimize the discharge cycle.

Summary

Mastering the sealing principle and failure rule of ball valve, combined with scientific maintenance process, can significantly reduce the risk of clutching. When encountering abnormal operation, strictly prohibit brutal operation, and prioritize the use of professional tools (e.g., gas injection leveling device) to solve the problem. Select the valve supplier with API certification to obtain customized maintenance programs.