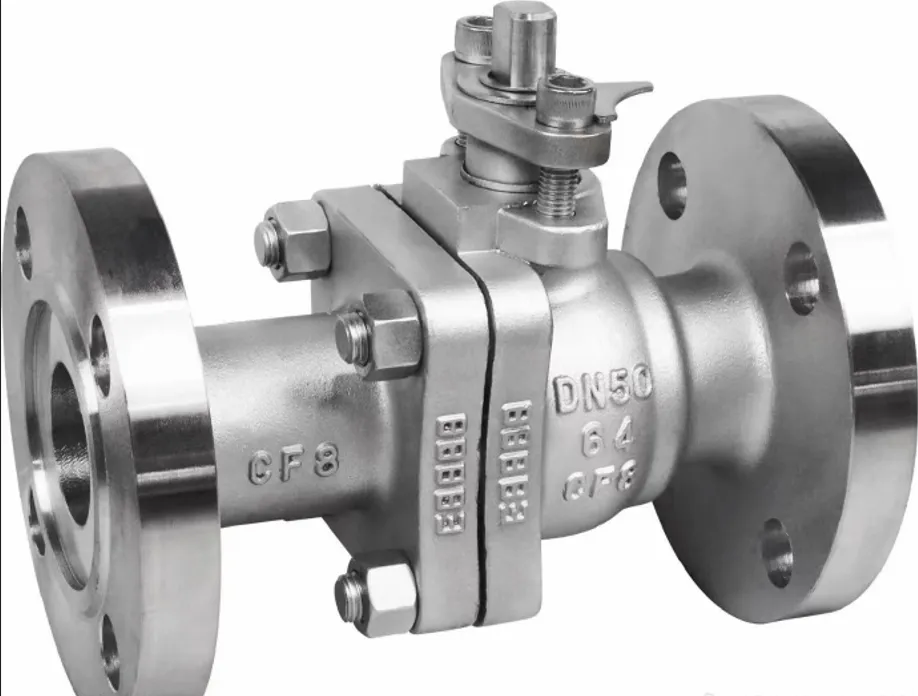

In the industrial field, ball valves, as a common pipeline control equipment, its performance and stability are crucial. However, ball valves may have internal leakage problems during use, which not only affects the normal operation of the piping system, but also poses safety hazards. In this article, we will introduce the causes of internal leakage of ball valves and how to determine the internal leakage of natural gas ball valves in detail, to help industrial practitioners better understand and solve this problem.

Causes of Ball Valve Internal Leaks

Problems during construction

Improper transportation and lifting: Improper handling during the transportation and lifting of the ball valve may result in damage to the valve as a whole, which in turn may lead to internal leakage.

Inadequate factory treatment: Some ball valves are shipped from the factory without adequate drying and anticorrosion treatment, even though they have been hydrostatically tested. This may lead to rusting of the sealing surface after prolonged storage, thus causing internal leakage.

Inadequate on-site protection: At the construction site, if the valve is not protected by blind plates at both ends, rainwater, sand and other impurities may enter the valve seat, resulting in leakage.

Installation problems: When installing the ball valve, if the valve seat is not injected with grease, or if the valve parts are burned during welding, internal leakage may be triggered.

Valve not installed fully open: If the ball valve is not installed in a fully open state, welding spatter may damage the ball or seat, resulting in internal leakage.

Construction remnants: welding slag and other construction remnants may scratch the sealing surface, resulting in internal leakage.

Inaccurate limits: If stem drive bushings or other accessories are assembled at a misaligned angle at the factory or during installation, this may also cause the valve to leak.

Problems during operation

Lack of maintenance: For cost considerations, some operations managers may neglect the maintenance of ball valves. Lack of scientific approach to valve management and maintenance may lead to early equipment failure.

Improper operation: Failure to follow proper maintenance procedures or improper operation may trigger internal leakage.

Sealing surface damage: during normal operation, construction remnants may scratch the sealing surface; improper pipe cleaning may also lead to sealing surface damage.

Long-term inactivity: long-term non-maintenance or inactivity of the valve may lead to the valve seat and ball hold, switching the valve caused by sealing damage.

Switch not in place: ball valve in the switching process, if the tilt angle is too large (generally more than 2 ° ~ 3 °), it may trigger leakage.

Valve stem stop block problem: after a long time of use, rust, dust and other debris may accumulate between the valve stem and stem stop block, resulting in the valve can not be rotated into place.

Actuator Limit Problem: If the limit of the electric actuator is inaccurate due to rust, hardened grease or loose limit bolts, it may also cause internal leakage.

Valve position setting problem: The valve position of electric actuator is set forward and not in place, which will also cause internal leakage.

Lack of periodic maintenance: sealing grease, if not replaced for a long time, will become dry and hardened, and accumulate behind the elastic valve seat, hindering the movement of the valve seat and causing seal failure.

Natural gas ball valve internal leakage judgment method

Fixed shaft ball valves are a common type of valve used on natural gas pipelines in the United States. In order to determine if a natural gas ball valve is leaking internally, the following methods can be used:

Check the drain nozzle: Turn the valve to the fully open or fully closed position and vent the gas through the drain nozzle on the valve body. If the gas can be completely discharged, it proves that the seal is good; if there is always gas discharged, it may indicate that the valve is leaking.

Observe pressure changes: During the discharge process, you can observe the pressure changes at the discharge nozzle. If the pressure persists and cannot be completely released, then it is likely to be a sign of internal leakage in the valve.

By using the above methods, U.S. industry practitioners can identify and solve the internal leakage problem of natural gas ball valves in a timely manner to ensure the safe and stable operation of the pipeline system. It is also recommended that ball valves be maintained and inspected on a regular basis to prevent internal leakage problems from occurring.

Ball valve internal leakage causes and natural gas ball valve internal leakage judgment method

Ball valve internal leakage causes and natural gas ball valve internal leakage judgment method