When disassembling, cleaning and assembling ball valves, it is vital to follow a series of clear and detailed steps to ensure not only the performance of the ball valve, but also the safety of the operation. The following is a guide for U.S. readers to make the process clearer and easier to understand.

Safety Preparation Before Disassembly

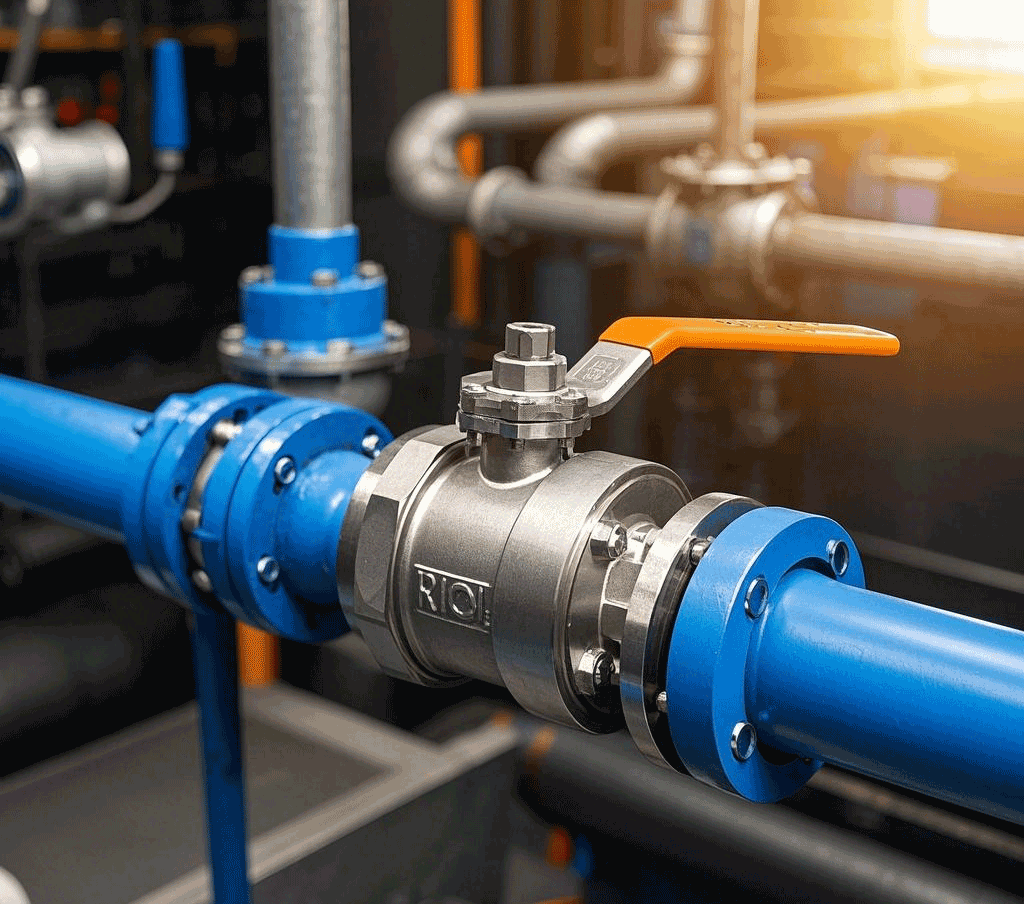

Make sure there is no pressure: Before disassembling a ball valve, it is important to ensure that the piping upstream and downstream of the ball valve has been completely depressurized. This is a critical step in preventing accidents.

Disassembly and disassembly precautions

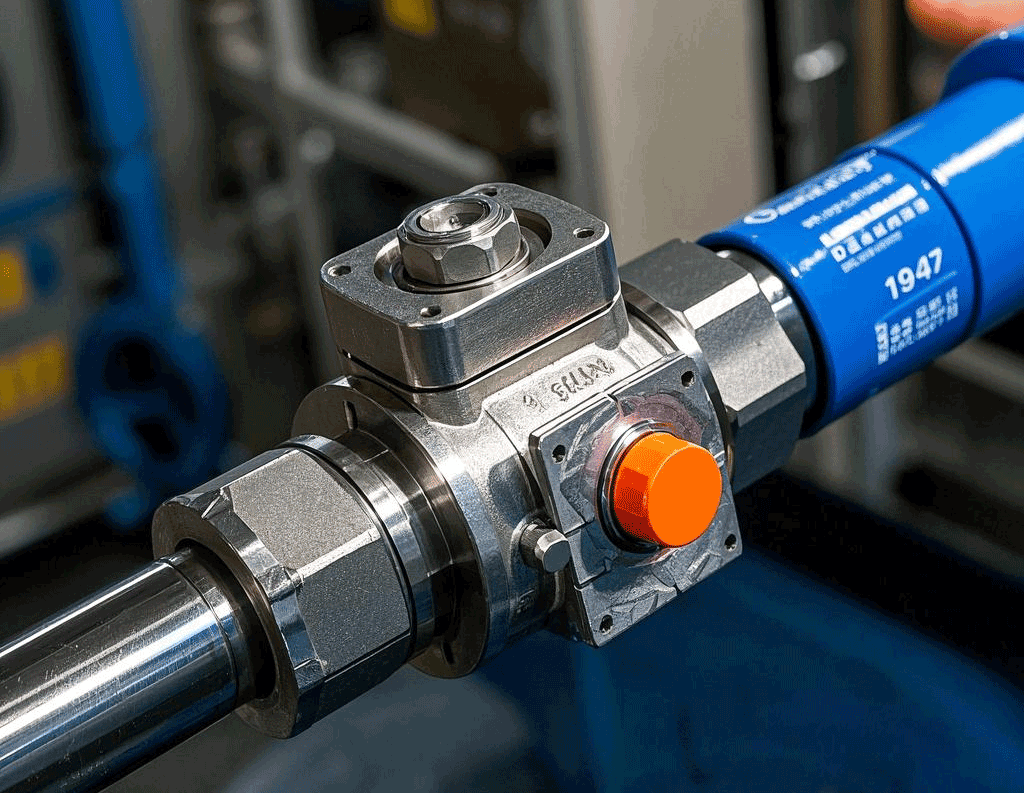

Protect the sealing surface: When disassembling the ball valve, special care should be taken to avoid damaging the sealing surface of the parts, especially the non-metallic parts. When removing the O-ring, it is recommended that a special tool be used to minimize the risk of damage.

Tips when assembling

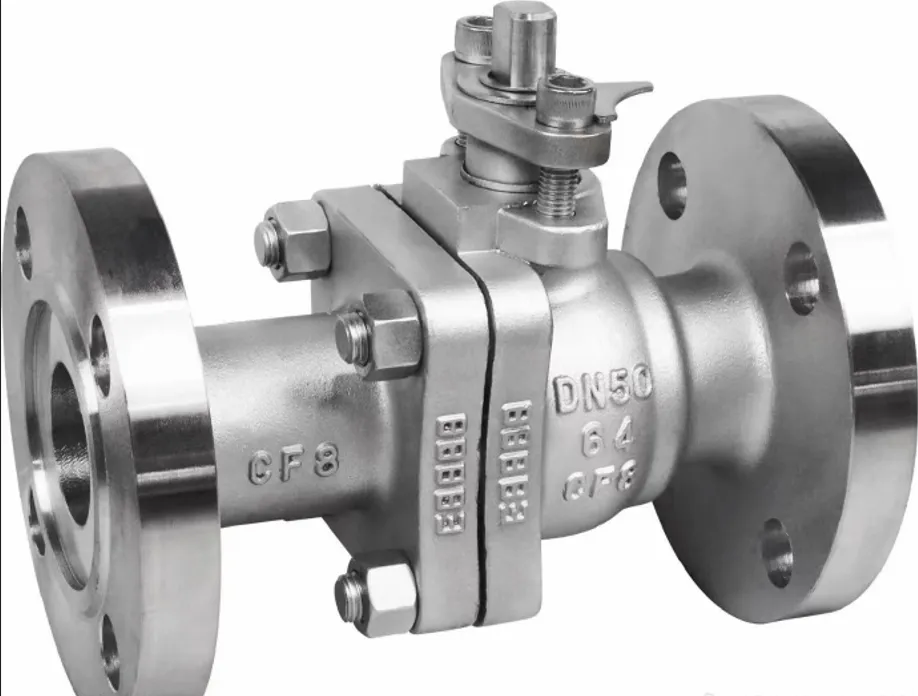

Tighten bolts evenly: When assembling the flange, the bolts must be tightened symmetrically, gradually and evenly. This ensures a tight flange connection and prevents leakage.

Selection and use of cleaning agents

Compatibility check: The cleaning agent should be compatible with the rubber, plastic and metal parts in the ball valve as well as the working medium (e.g. gas). For gas as the working medium, metal parts can be cleaned with gasoline, while pure water or alcohol is recommended for non-metallic parts.

Cleaning method: Disassembled individual parts can be cleaned by immersion washing. For metal parts with non-metallic parts still attached, they can be scrubbed with a clean silk cloth impregnated with cleaning agent (taking care to avoid shedding fibers). During the cleaning process, grease, dirt, adhesive and dust should be thoroughly removed.

Special treatment of non-metallic parts: non-metallic parts should be removed from the cleaning agent immediately after cleaning and avoid prolonged immersion to prevent damage.

Evaporation and assembly: After cleaning, it is necessary to wait for the cleaning agent on the washed wall surface to evaporate completely before assembly. To avoid rust and dust contamination, do not leave the parts for a long time.

Preparation of new parts

New Parts Cleaning: New parts also need to be cleaned before assembly to ensure that their surfaces are clean and free of impurities.

Use of Grease

Selection of suitable grease: Grease should be compatible with the metal material, rubber parts, plastic parts and the working medium of the ball valve. For the case of gas as the working medium, you can use such as special 221 grease. Apply a thin layer of grease to the seal mounting grooves, rubber seals, and stem sealing and friction surfaces to minimize friction and wear.

Cleaning requirements during assembly

Maintain cleanliness: During assembly, make sure that no metal shavings, fibers, grease (unless used as specified), dust or other impurities contaminate, adhere to, or remain on the surfaces of the parts or enter the internal cavities. This ensures sealing performance and operational efficiency of the ball valve.

By following these guidelines, you can efficiently and safely complete the disassembly, cleaning and assembly of ball valves to ensure stable performance and extend their service life.

Ball Valve Disassembly, Cleaning and Assembly Guide: Steps to Ensure Efficiency and Safety