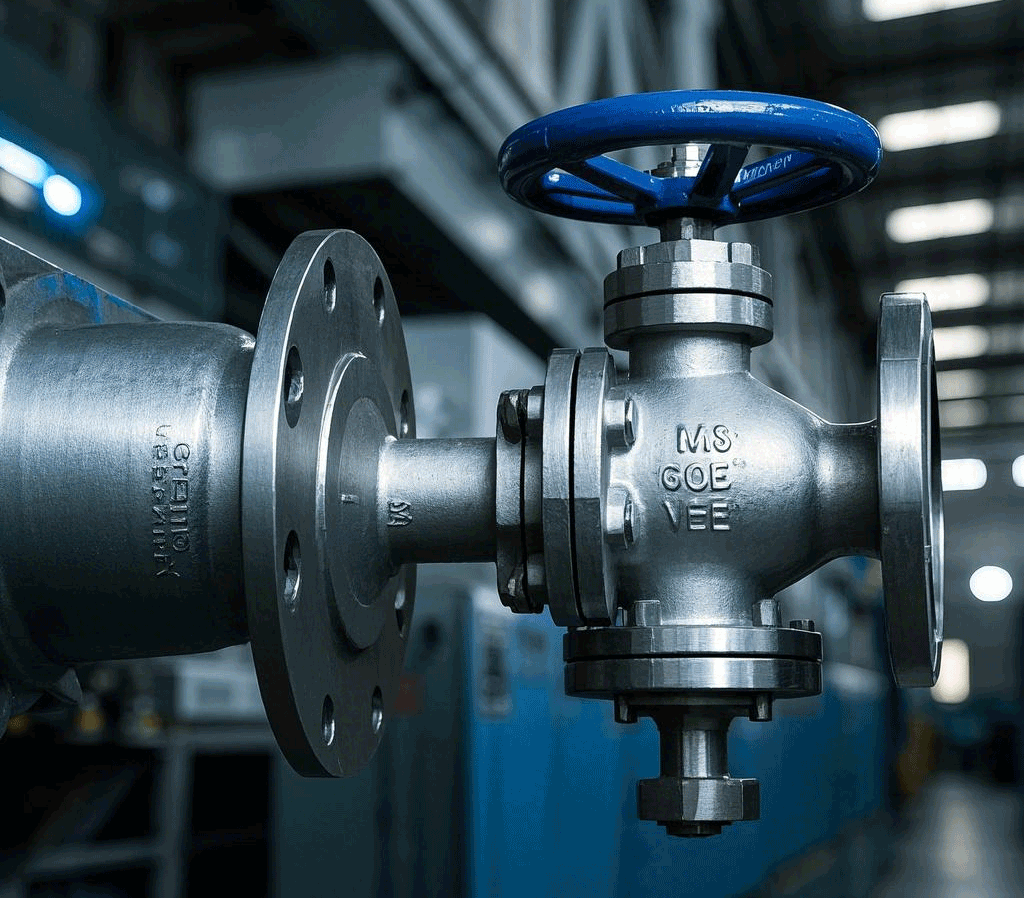

Soft Seal Gate Valve Introduction Soft Seal Gate Valve, also known as resilient seated gate valve, is a manual valve widely used in water conservancy projects, mainly used for connecting pipeline media and control switch. Its structure consists of valve seat, bonnet, gate, gland, stem, handwheel, gasket and hexagonal bolts and other key components. Inside and outside the valve runner, advanced electrostatic powder coating process is adopted and baked at high temperature to ensure the smoothness of the runner mouth and the wedge-type groove mouth inside the gate valve, and at the same time, give the valve a distinctive color appearance. Usually, the soft seal gate valve used in water conservancy projects adopts blue high-gloss design, while the one used in fire pipeline adopts red high-gloss, which is popular among users. It can be said that the soft seal gate valve is a valve designed for water conservancy projects. Types and applications of soft seal gate valves As a common manual switching valve on the pipeline, soft seal gate valves are widely used in water plants, sewage pipes, municipal drainage projects, fire pipeline projects and industrial pipelines, suitable for slightly non-corrosive liquid and gas media. In addition, the soft seal gate valve can also be customized according to the needs of field use, such as open stem, dark stem, extension stem, buried type, electric, pneumatic and other types to meet the needs of use in different scenarios.

Advantages of soft seal gate valve

- Affordable: soft seal gate valve is mostly made of ductile cast iron QT450, compared with cast steel, stainless steel and other materials, its cost is more affordable. For engineering bulk purchasing, this is undoubtedly a huge advantage, while ensuring the quality of the valve.

- Good sealing effect: The gate plate of the soft seal gate valve is designed with encapsulated elastic rubber, and the internal wedge structure. Through the top handwheel mechanism rotates to make the wire rod down, driving the elastic gate plate downward pressure and internal wedge-type groove mouth sealing. Due to the elastic rubber gate plate has expansion and extrusion performance, so it can achieve good sealing effect, especially suitable for water conservancy projects and non-corrosive media.

- Easy to maintain: the construction design of soft seal gate valve is simple and clear, easy to disassemble and install. When the valve is used for a long time, the flexible gate inside the gate valve may lose its elasticity due to frequent switching, resulting in poor sealing. At this time, the maintenance personnel can be directly disassembled to replace the gate plate, without the need to dismantle the entire valve, which saves time and reduces maintenance costs.

Disadvantages of soft seal gate valve

Of course, everything has its limitations. The core advantage of the soft seal gate valve is that its soft sealing resilient gate plate can automatically fill the gap to achieve good sealing and air tightness. However, the elastic rubber gate plate cannot be used continuously in high temperature environment over 80℃, medium containing hard particles or corrosive medium, or it will lead to deformation, breakage or corrosion of the gate plate, which will lead to leakage of the pipeline. Therefore, the soft seal gate valve is only suitable for non-corrosive, non-particulate, non-abrasive media environment. In summary, the soft seal gate valve is widely used in water conservancy projects and non-corrosive media pipelines for its advantages of affordability, good sealing effect and easy maintenance. However, it is also necessary to pay attention to its limitations in the use, to ensure that the media conditions meet the use of the valve requirements.