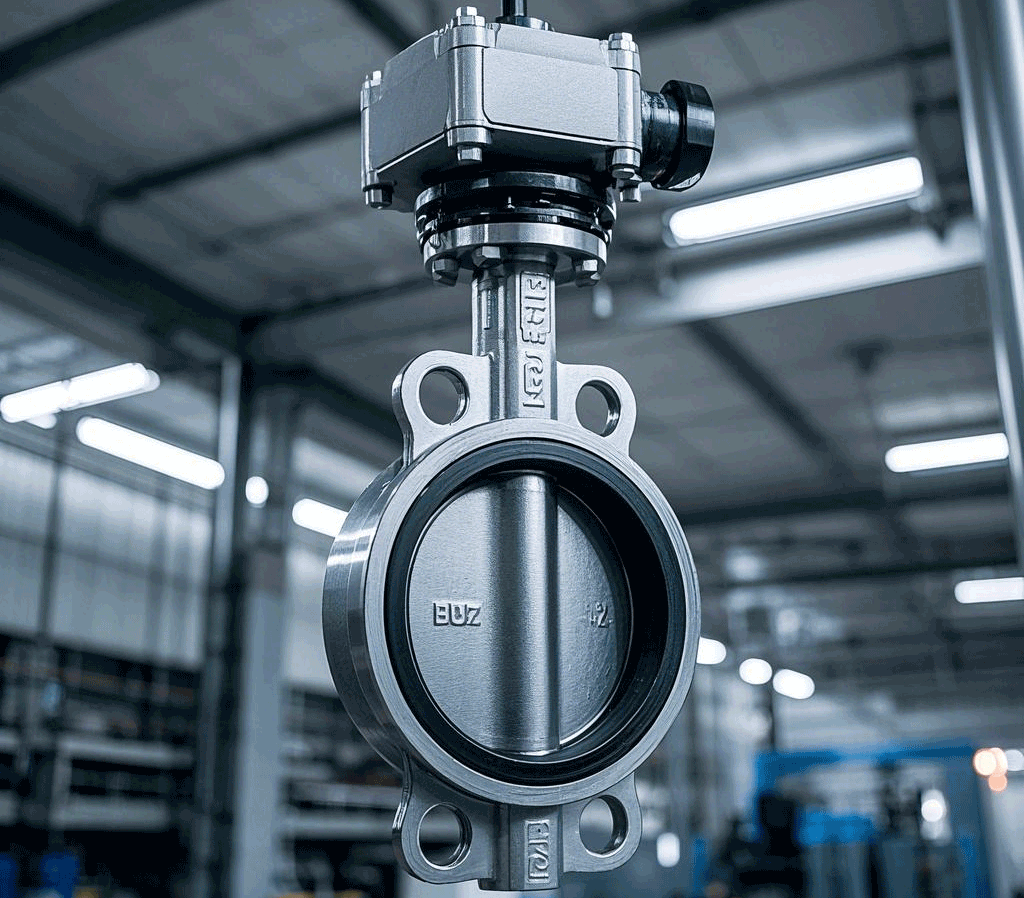

Butterfly valves, as an important device in the field of fluid control, are widely appreciated in American industry for their unique advantages. Below, we’ll take a closer look at a few of the butterfly valve’s highlights as well as shortcomings to look out for.

The significant advantages of butterfly valve:

Convenient and efficient operation: the butterfly valve’s opening and closing process is both rapid and labor-saving, and the fluid resistance is also very small, which means it can be operated frequently without causing excessive energy consumption or wear and tear. The butterfly valve is undoubtedly an ideal choice for occasions that require frequent flow adjustment.

Compact and lightweight structure: the butterfly valve has a simple and clear structural design, compact size and light weight. This not only facilitates installation and maintenance, but also greatly saves space, making the butterfly valve maneuverable in various compact industrial environments.

Strong slurry handling ability: the butterfly valve performs well in transporting slurry and other viscous media, with little or no liquid buildup at the mouth of the pipeline. This is undoubtedly a huge advantage for industrial applications that need to handle this type of media.

Good low-pressure sealing effect: In low-pressure environments, butterfly valves are able to achieve good sealing effect, ensuring that the medium will not leak. This is essential to ensure the continuity and safety of industrial production.

Outstanding regulating performance: butterfly valve is not only suitable for simple cut-off and connecting operation, but also has good regulating performance. By fine-tuning the opening degree of the butterfly plate, the flow rate of the medium can be precisely controlled to meet different production needs.

The shortcomings of butterfly valve:

Of course, butterfly valve is not perfect. The following are a few shortcomings that need to be noted:

Restricted range of use: butterfly valves have a relatively small range of operating pressure and operating temperature. This means that in some extreme conditions, butterfly valves may not be able to meet the requirements, and need to choose other types of valves.

Sealing performance to be improved: although butterfly valves can achieve good sealing effect under low-pressure environment, their sealing performance may be affected under high-pressure or high-temperature conditions. Therefore, when choosing butterfly valves, it is necessary to weigh them according to specific application scenarios.

To summarize, butterfly valves play an important role in the U.S. industry with their advantages of easy operation, compact structure, strong slurry handling ability and good low-pressure sealing effect. However, it is also necessary to pay attention to its shortcomings such as limited range of use and sealing performance that needs to be improved. Choosing the right type of valve is essential to ensure the smooth running of industrial production.