Gate valve, as a widely used general purpose valve, its importance is self-evident in many industries such as water conservancy, metallurgy and so on. In the industrial field, the use of gate valve performance is widely recognized. This article will provide readers with a comprehensive guide from the structure of the gate valve, the use of occasions, troubleshooting and quality testing.

First, the structure of the gate valve

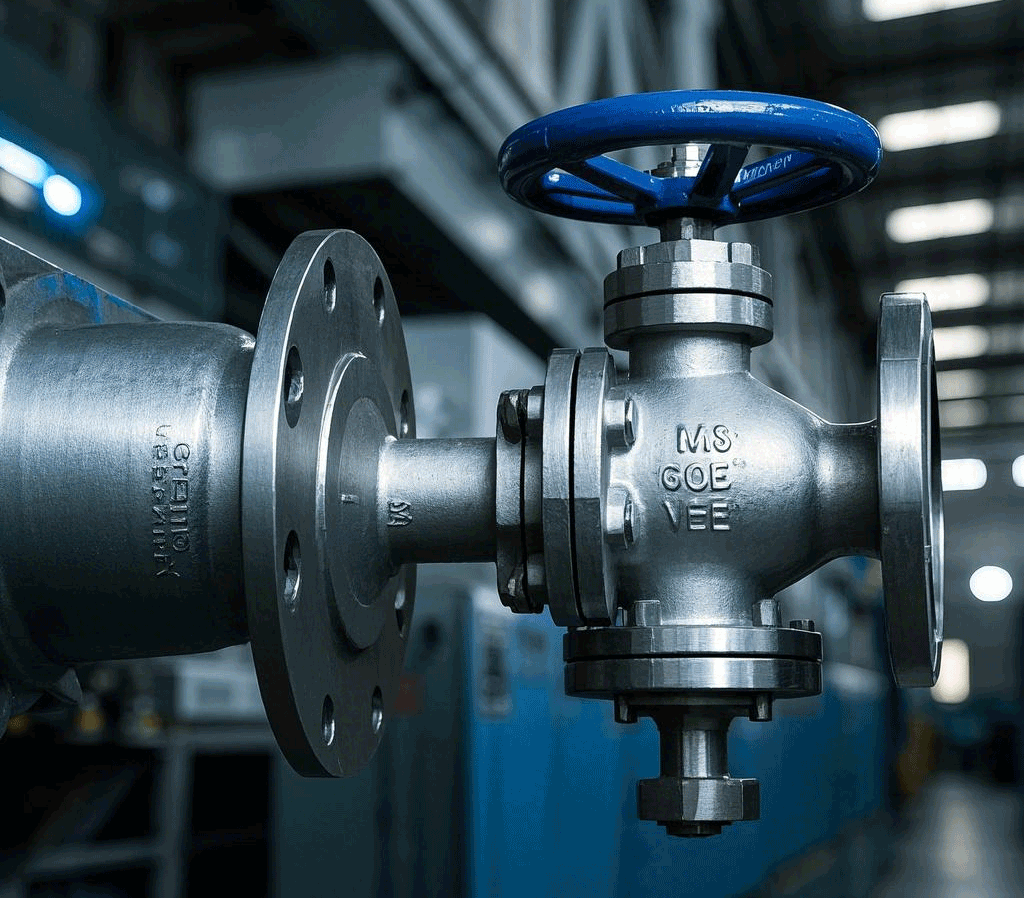

Gate valves control the opening and closing of the channel through the relative position change of the gate and the valve seat. Gate valves are mainly composed of valve body, seat, gate, stem, bonnet, stuffing box, stuffing gland, stem nut and handwheel. The mating surfaces of the gate and seat are precisely ground to ensure the tightness of the valve when it is closed.

Gate valves can be categorized into two main types, wedge-type and parallel-type, according to their structural shape. Wedge gate valve gate is wedge-shaped, using the wedge effect to achieve sealing. The sealing surfaces of the parallel gate valve are parallel to each other and perpendicular to the centerline of the channel. In addition, according to the stem movement, the gate valve can also be divided into open stem gate valve and dark stem gate valve.

Second, the application of gate valve and selection principles

Flat gate valve

Flat gate valve is widely used in oil, natural gas pipeline, oil pipeline and storage equipment, mining mouth device and pipeline with suspended particles. In addition, it is also suitable for city gas pipeline and water works.

When selecting the flat gate valve, you need to choose the appropriate model according to the specific use of the occasion. For example, oil, natural gas pipeline can choose a single gate or double gate plate gate valve; with suspended particles in the pipeline can choose knife-shaped plate gate valve.

Wedge gate valve

Wedge gate valve is widely used in various types of valves, especially for the need for long-term sealing of harsh conditions, such as high temperature and high pressure media. In the electric power, petroleum refining, petrochemical, marine petroleum and urban construction of water works and sewage treatment works and other fields, the wedge gate valve plays an important role.

Selection of wedge gate valve, need to consider the characteristics of the medium, the use of conditions and installation location and other factors. For example, for high temperature and high pressure media, should be able to withstand high temperature and high pressure wedge gate valve; when the installation height is limited, you can choose the dark rod wedge gate valve.

Third, the common faults and maintenance of the gate valve

Gate valve in the process of use often leakage, corrosion and abrasion and other faults. Leakage is divided into external leakage and internal leakage, external leakage is common in the stuffing box and flange connections, internal leakage is caused by the valve is not closed tightly.

Maintenance of gate valves, according to the different faults to take appropriate measures. For example, for external leakage, the packing should be pressed or replaced gasket; for internal leakage, the sealing ring should be replaced or the sealing surface should be ground. In addition, attention should also be paid to prevent the occurrence of corrosion and abrasion, such as the use of filler containing retardant, to avoid excessive torque when closing the valve.

Fourth, the gate valve quality inspection

In the market, iron gate valve occupies an important position. Quality inspectors need to be familiar with the national standard GB/T12232-2005 (although the Chinese standard, but can be analogous to understand the relevant U.S. standards or ASTM and other international standards), and according to the standard of iron gate valve quality inspection.

The testing items mainly include marking, minimum wall thickness, pressure test and shell test. Among them, wall thickness, pressure and shell test are mandatory and critical items. If there are unqualified items, can be directly determined as unqualified products.

In short, as a product quality inspectors or users, it is important to understand the structure of the gate valve, application occasions, troubleshooting and quality testing and other aspects of knowledge. This helps to ensure the safety and reliability of the gate valve in the use of the process, thus ensuring the smooth progress of industrial production.