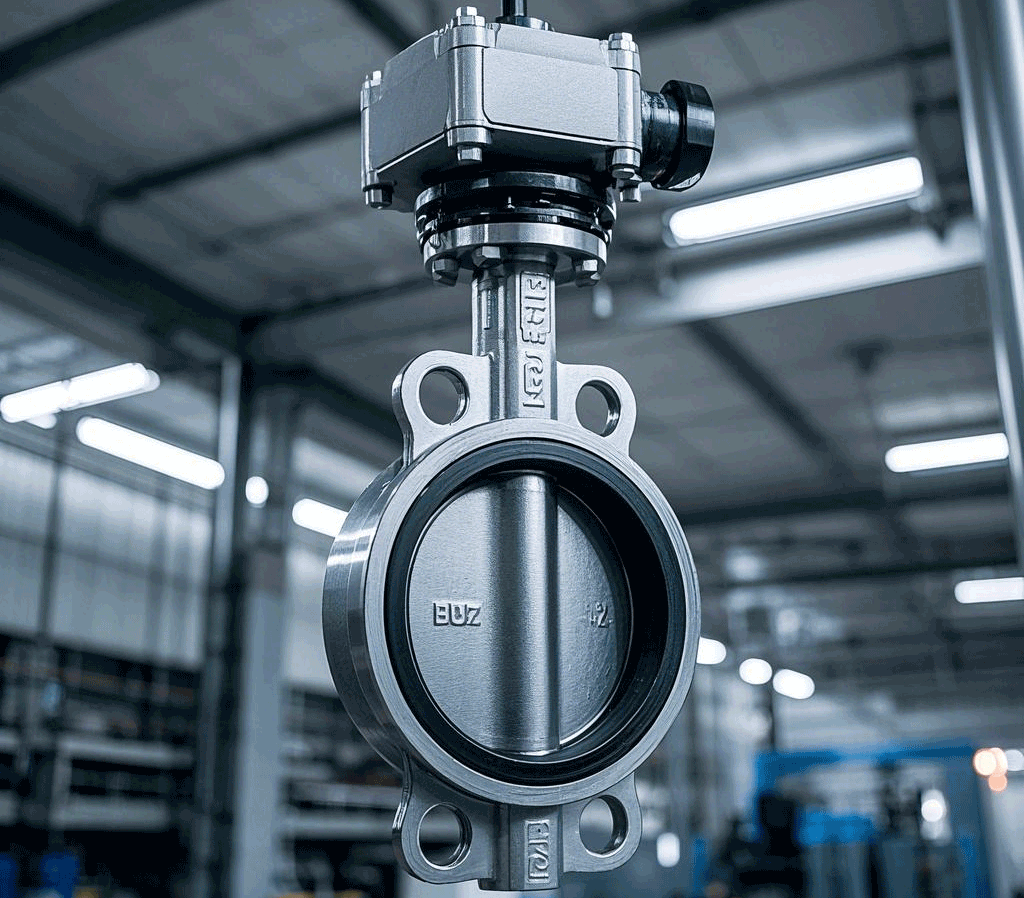

As the core equipment of industrial fluid control, the selection of electric butterfly valve and pneumatic butterfly valve directly affects the efficiency and safety of the system. In this paper, from the technical parameters, application scenarios to maintenance costs, an all-round comparison of the two valve selection conditions.

First, the core performance comparison

Comparison dimension Electric butterfly valve Pneumatic butterfly valve

Driving method Motor drive (AC/DC power supply) Compressed air drive (air source system required)

Response speed Slower (5-30 seconds) Fast (1-5 seconds)

Adjustment Accuracy ±1%~±5% (with positioner) ±3%~±8

Explosion-proof rating Customized (not intrinsically safe) Naturally explosion-proof (suitable for hazardous areas)

Energy dependent Dependent on stable power supply Dependent on gas source stability

Second, the selection of key indicators

- medium characteristics

High temperature and high pressure: electric butterfly valve (maximum temperature 550 ℃, bearing pressure 42MPa).

Corrosive media: pneumatic butterfly valve (optional stainless steel / fluorine material). - Control requirements

Precise regulation: electric butterfly valve (with PID control).

Fast cut-off: pneumatic butterfly valve (emergency cut-off ≤ 3 seconds). - Environmental conditions

Explosion-proof area: pneumatic butterfly valve (ATEX/IECEx certification).

Remote areas: electric butterfly valve (no need for gas infrastructure).

Typical Application Scenarios

Motorized butterfly valve is suitable for

Water treatment plant: regulating the flow of water into the sedimentation tank (DN300~DN2000).

Thermal power plant: control steam pipeline pressure (temperature ≤ 540 ℃).

Chemical reactor: accurate proportioning of corrosive media (such as concentrated hydrochloric acid).

Pneumatic butterfly valve is applicable

Petroleum storage tanks: quickly cut off flammable liquids (such as gasoline).

Mine ventilation: regulating the flow of dusty gas (wear-resistant lining design).

Food processing: fluid control in aseptic environment (316L stainless steel material).

Four, economic analysis

Cost type Electric butterfly valve Pneumatic butterfly valve

Initial investment Higher (including motor and controller) Lower (only actuator and valve body)

Running Costs Electricity Consumption Gas Source Energy Consumption (approx. 0.5-1.5 bar)

Maintenance costs Regular lubrication of motor bearings required Replacement of pneumatic seals required (2-3 years)

V. Selection Decision Tree

Is explosion-proof required?

Yes → pneumatic butterfly valve

No → electric butterfly valve

Requirement of adjustment precision?

≤±2% → electric butterfly valve

≥±5% → Pneumatic Butterfly Valve

Installation space limitation?

Narrow → Pneumatic butterfly valve (compact structure)

Sufficient → motorized butterfly valve (need control cabinet)

Industry standards and certification

Motorized Butterfly Valve: IEC 60529 (protection level), API 609 (design standard).

Pneumatic butterfly valve: ISO 5211 (actuator interface), ASME B16.34 (pressure level).

Summarize

The choice between electric and pneumatic butterfly valves depends on control accuracy, environmental conditions and cost budget. If you need explosion-proof or fast response, pneumatic butterfly valve is better; if you need precise adjustment or no air source environment, electric butterfly valve is better. Contact us for customized options to ensure compliance with ISO 9001/API certification.