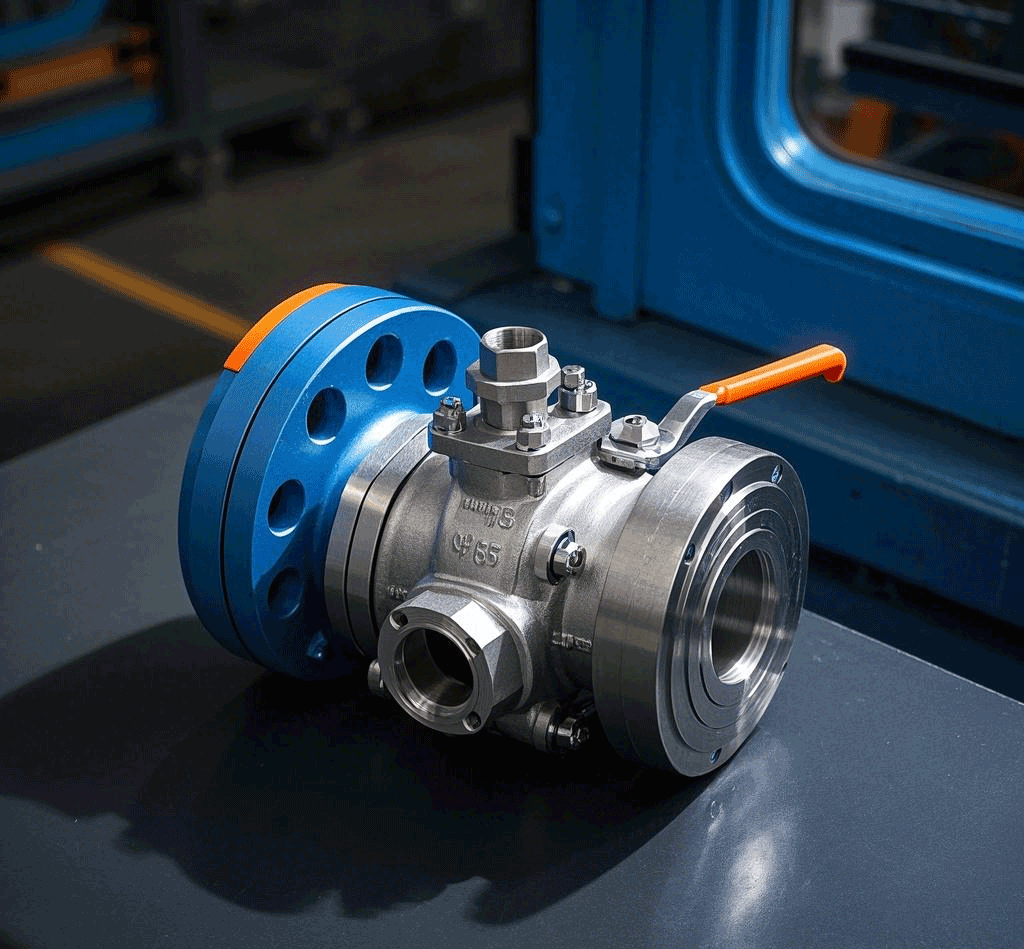

Electric ball valve working principle overview: electric ball valve, this set of electric actuator and ball valve in one of the innovative products, with its unique design and function, become throttling, cut off, cut off and diversion and other fluid control tasks in the best. Its core component – plug body, using a sphere design, only need to rotate 90 degrees to complete the switching action, easy and fast operation.

The working principle of electric ball valve is revealed

The mystery of the operation of the electric ball valve lies in its built-in electric actuator. This intelligent device through the regulation of electric flow, receive 4-20MA and 220VAC standard signal, drive the motorized unit drive gear turbine worm gear, so as to accurately control the opening and closing status of the ball valve. Whether it is to distribute media flow, change the flow direction, or adjust the degree of spool rotation (i.e., the valve’s opening is proportional to the control fluid), electric ball valves can easily cope with the realization of precise control.

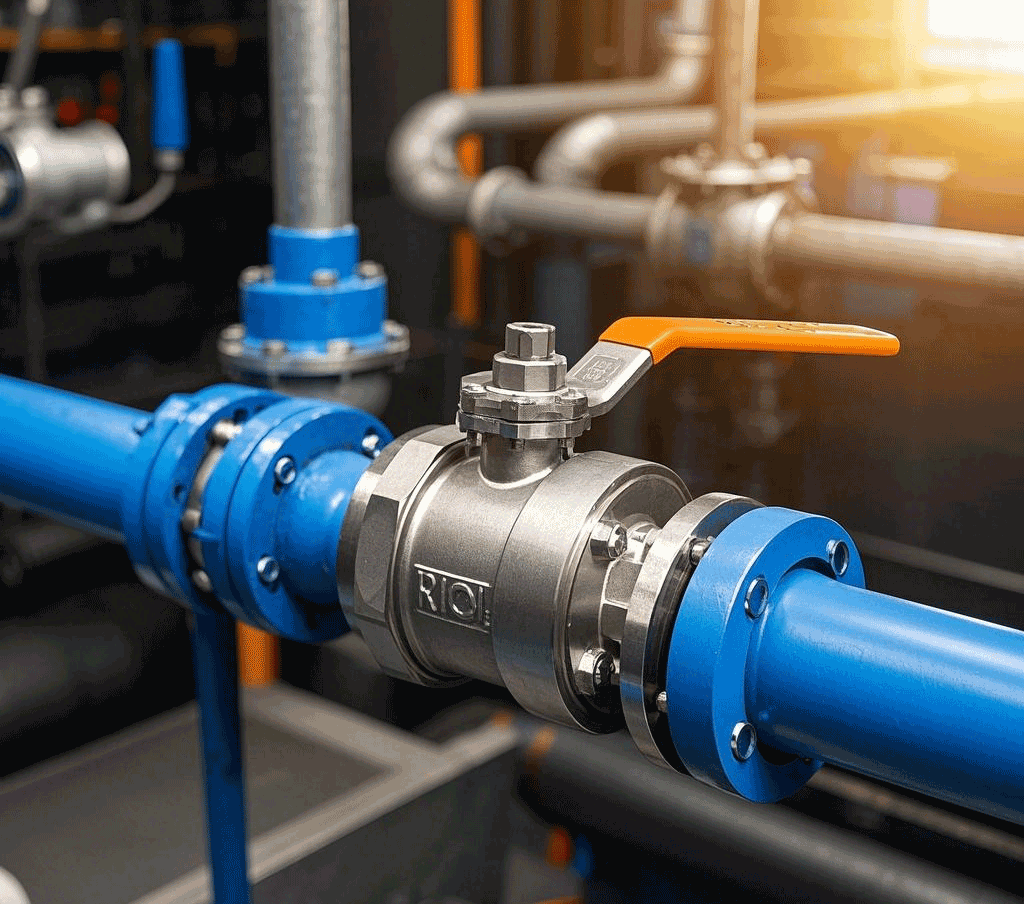

Wide application of electric ball valves

Motorized ball valves play an important role in industrial production with their intelligent operation and no need for human intervention. Facing the challenges of different environmental conditions, electric ball valves show a high degree of adaptability and flexibility:

Low-temperature and low-pressure environment: in such environments, the material of the motorized ball valve does not require too much adjustment to maintain stable performance.

High-pressure high-temperature environment: for more severe high-pressure high-temperature conditions, electric ball valves use high-temperature and high-pressure resistant materials, such as stainless steel, alloys, etc., to ensure that they can still work stably under extreme conditions.

Internal parts optimization: In order to reduce spool damage, improve media flow efficiency, avoid coking and clogging, the internal parts of the electric ball valve are carefully designed and optimized.

Anti-vibration design: when the electric ball valve is opened, anti-vibration mechanical devices can be installed to effectively protect the internal structure of the spool and extend the service life.

In summary, electric ball valves have become the preferred products in the field of fluid control due to their features of pressure resistance, temperature resistance, corrosion resistance, low flow resistance, long service life and wide range of applications. No matter what kind of environmental conditions, electric ball valves can provide efficient and intelligent fluid control solutions to help industrial production more smoothly and efficiently.

Overview of the working principle of electric ball valves