In industrial fluid control systems, globe valves and gate valves are two common types of valves, each of which has unique characteristics and application scenarios. Understanding their differences is critical to proper selection and installation. The following is a globe valve vs. gate valve comparison guide for U.S. customers.

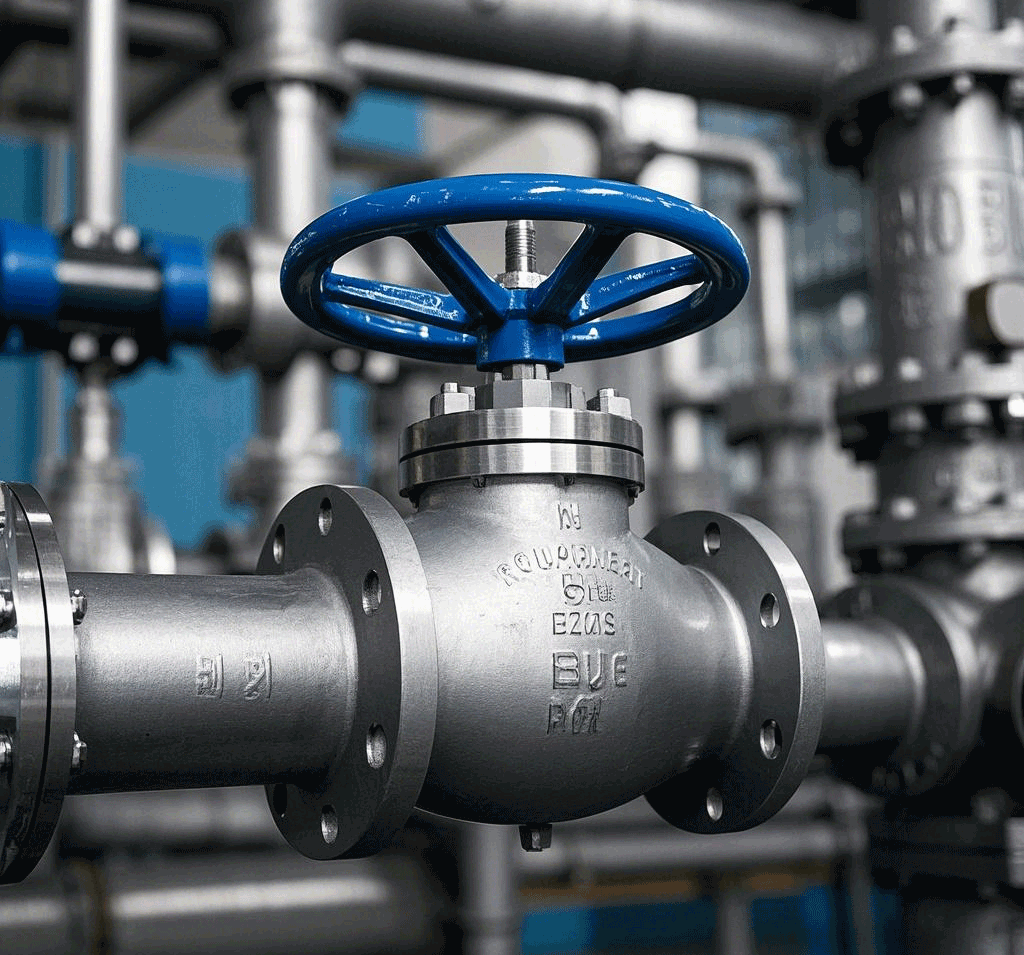

Structural Differences

Special care is needed when selecting valves for space-constrained installations. Gate valves rely on media pressure to tightly fit the sealing surface for a leak-free effect. However, when opening and closing, the spool and seat sealing surfaces are in constant contact and friction, which can easily lead to abrasion of the sealing surfaces. Especially when the gate valve is close to the closed state, the pressure difference between the front and back of the pipeline increases, exacerbating the wear of the sealing surface.

Gate valve structure is relatively complex, under the same caliber than the globe valve high, while the globe valve is longer. In addition, gate valves are also divided into two types: open stem and concealed stem, while globe valves have no such classification.

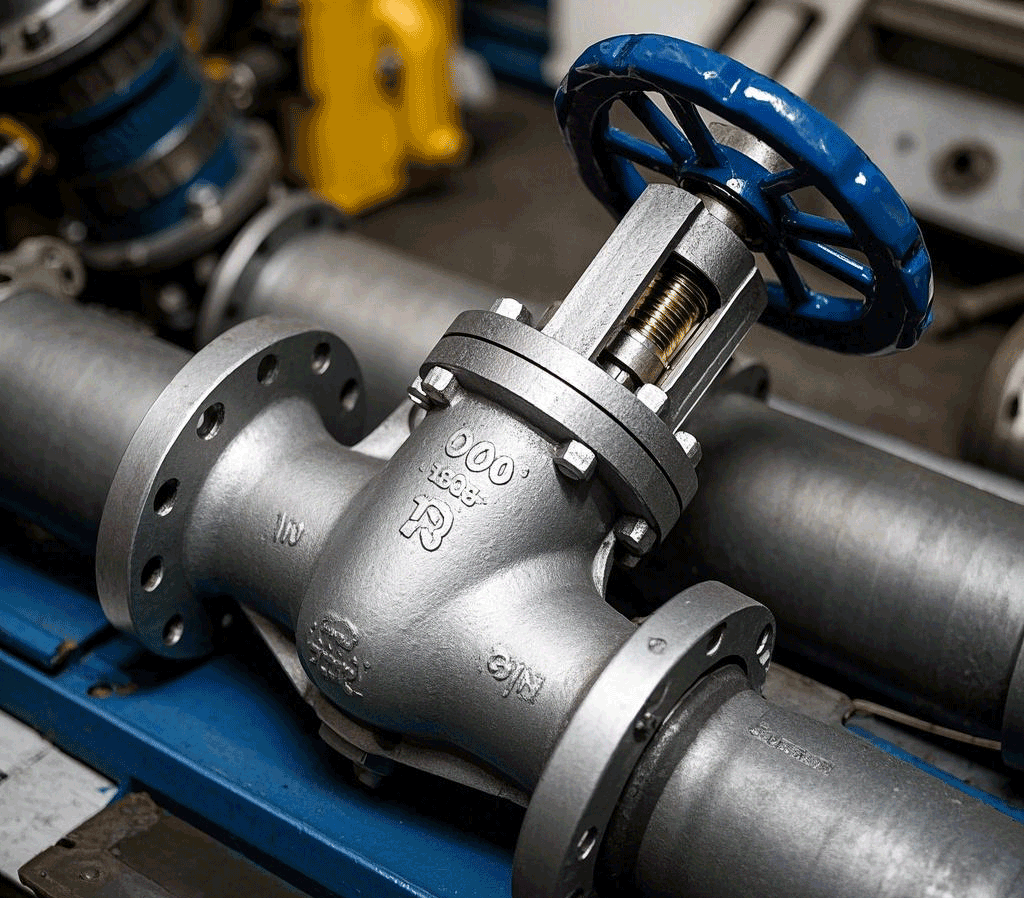

Working Principle

When the globe valve opens and closes, the valve stem rises, and the handwheel rotates with the valve stem and rises and falls. While the gate valve opening and closing, the handwheel is fixed, only the valve stem lift. Gate valves require fully open or fully closed, no specific import and export direction requirements; globe valves need to be installed according to the direction of the specified, usually from top to bottom flow.

Flow Control

Gate valve is only used for fully open or fully closed, large stroke, opening and closing time is long. Globe valve valve plate stroke is small, can stay in motion to regulate the flow. Therefore, the globe valve can be used for both cut-off and flow regulation.

Performance characteristics

Globe valve fluid resistance, opening and closing laborious, but the valve plate from the sealing surface is short, short opening and closing stroke. Gate valve is fully open, the medium flow resistance is almost zero, open and close to save energy, but the gate from the sealing surface far, open and close time is long.

Installation and flow direction

There is no specific requirements for the flow direction of the gate valve, the medium can flow in both directions. Globe valve needs to be installed according to the direction of the arrow, China’s provisions of the globe valve from top to bottom flow. Appearance, globe valve pipeline is not on the same level, the gate valve flow path is horizontal.

When fully open, gate valve flow resistance is small, globe valve flow resistance is large. Gate valve flow resistance coefficient of about 0.08 ~ 0.12, opening and closing force is small; globe valve flow resistance is 3-5 times the gate valve, opening and closing need to be forced to close to achieve sealing.

Installation

Globe valve has two installation methods: the medium from the spool below into or above into. Below the spool can extend the life of the packing, but the driving torque is large, the valve stem is easy to bend, applicable to small diameter valves (DN50 or less); above the opposite, applicable to large diameter valves (DN200 or more), electric globe valves are usually used in this way.

Sealing performance

Globe valve sealing surface for the spool trapezoidal side (shape varies according to the spool), spool off equivalent to the valve closure (although not strict, but with a stopping effect). Gate valve sealing by the side of the gate, the effect is not as good as the globe valve, spool off will not lead to valve closure.

Can globe valves and gate valves be mixed?