In today’s industry, there is a wide variety of valves with different structures and materials, and choosing the right valve is critical to ensuring the long-term stable operation of equipment. Incorrect valve selection or lack of knowledge about valves can be a potential risk for safety accidents. With the growing demand for valves in industry, it has become particularly important to understand the knowledge of valves.

Valves have two main characteristics: use characteristics and structural characteristics.

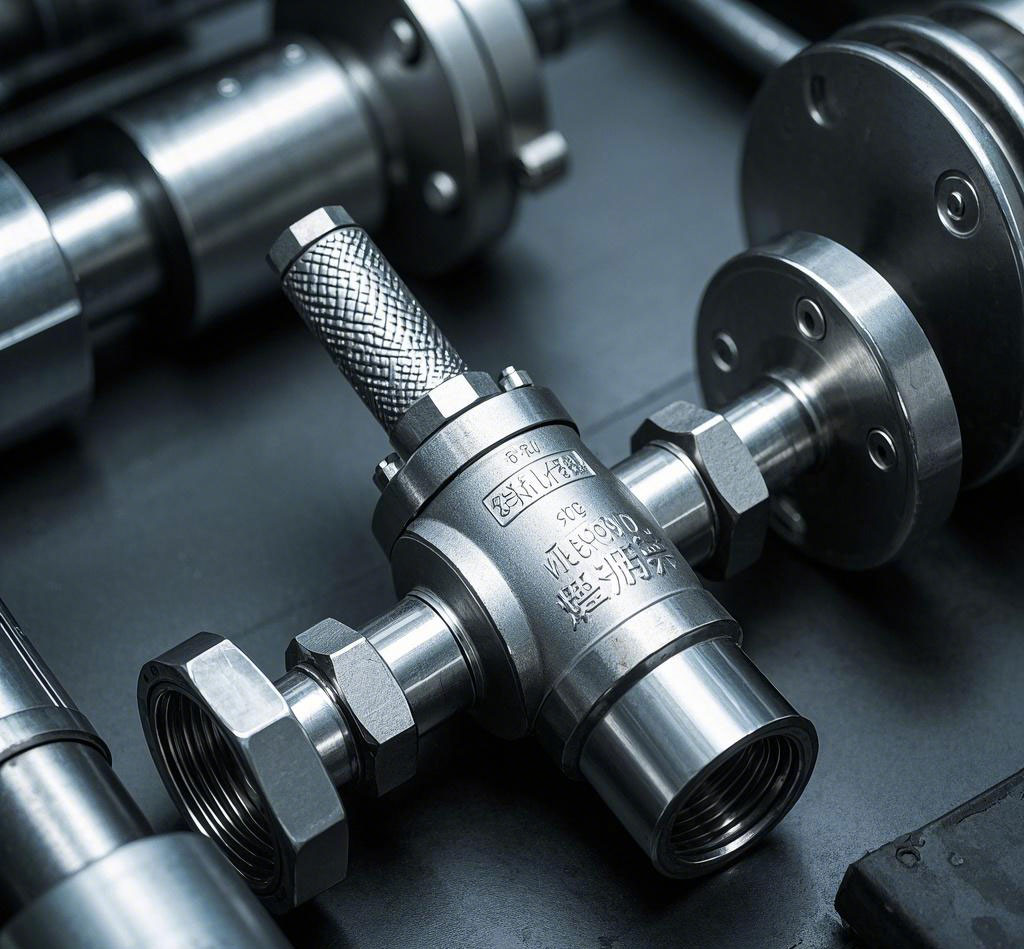

Use characteristics determine the main function and scope of application of a valve. This includes the type of valve (such as closed-circuit valves, regulating valves, safety valves, etc.); specific product types (such as gate valves, globe valves, butterfly valves, ball valves, etc.); valve key components (such as the valve body, bonnet, valve stem, valve flap, sealing surface) of the material; and the valve’s transmission mode.

Structural characteristics are related to the installation, maintenance and repair of the valve. This includes the structural length and overall height of the valve; the connection with the pipeline (such as flange connection, threaded connection, clamped hoop connection, external threaded connection, welded end connection, etc.); the form of the sealing surface; the structure of the valve stem (such as rotating stem, lifting stem) and so on.

Select the valve steps are as follows:

Define the purpose: first determine the use of the valve in the equipment, as well as the working conditions, such as the applicable medium, operating pressure, operating temperature, etc..

Determine the pipeline connection: according to the pipeline connected to the valve, select the nominal diameter and connection methods, such as flange, thread, welding, etc..

Selection of operation mode: decide whether to operate manually, electrically, electromagnetically, pneumatically or hydraulically, or electrically linked or electro-hydraulic linked.

Selection of materials: according to the medium, working pressure and working temperature of the pipeline, select the appropriate material of the valve shell and internal parts, such as gray cast iron, ductile iron, carbon steel, alloy steel, stainless steel and so on.

Select the type of valve: such as closed-circuit valves, control valves, safety valves, etc..

Determine the form of the valve: specifically, such as gate valves, globe valves, ball valves, butterfly valves and so on.

Set the valve parameters: for automatic valves, you need to determine the flow resistance, discharge capacity, back pressure and other parameters, and then determine the nominal diameter of the pipeline and valve seat hole diameter.

Determine the geometric parameters: including structure length, flange connection form and size, valve height, size and number of connection bolt holes, etc..

Reference to available information: Use valve catalogs and samples to select the appropriate valve.

The basis for selecting the valve includes:

Purpose and mode of operation: the purpose of the valve, working conditions and mode of operation.

Medium properties: working pressure, temperature, corrosiveness, whether it contains solid particles, whether it is toxic, flammable and explosive, viscosity and so on.

Fluid characteristics requirements: flow resistance, discharge capacity, flow characteristics, sealing grade, etc..

Installation and size requirements: nominal diameter, connection, connection size, external dimensions or weight limitations.

Additional requirements: such as the reliability of the valve, service life, explosion-proof performance of electric devices.

When selecting valves for control purposes, additional parameters such as method of operation, maximum and minimum flow requirements, pressure drop during normal flow and shut-off, and maximum and minimum inlet pressure of the valve need to be considered.

In order to select valves rationally and correctly, it is necessary to have an in-depth knowledge of the internal structure of each type of valve in order to make the right decision. Valves are the final control element of a pipeline, and their opening and closing parts control the way the medium flows in the pipeline. The flow characteristics of the valve must be considered when selecting the most suitable valve for the piping system.