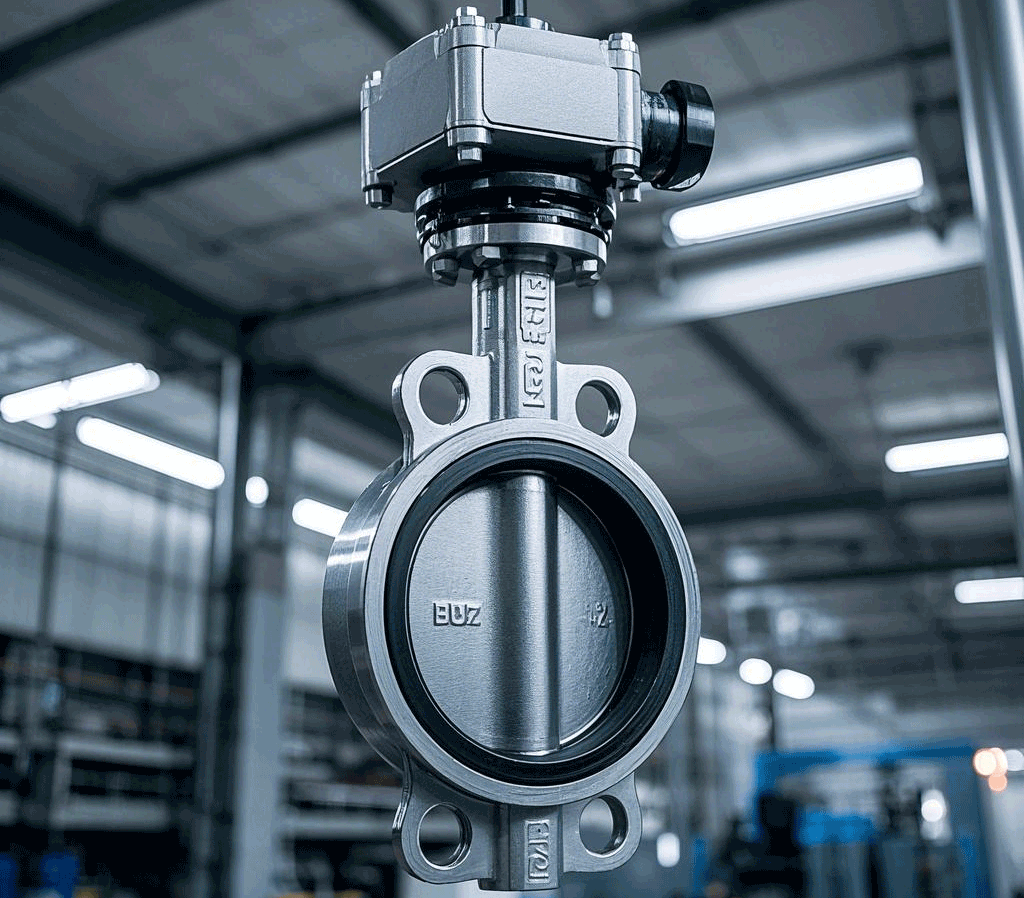

Butterfly valves, which play a key role in piping systems, have been widely used in many fields such as petroleum, chemical, metallurgy, hydropower and so on. However, with the continuous progress of industrial technology, the performance of traditional butterfly valves in some extreme working conditions has been difficult to meet the demand. For this reason, a new type of butterfly valve called high-performance triple eccentric bi-directional hard seal butterfly valve came into being, which is leading the new trend of butterfly valve technology with its excellent performance and wide application prospects.

Traditional butterfly valves use rubber and PTFE as sealing materials, but due to the limitation of structural characteristics, they are insufficient in high temperature and pressure resistance, corrosion resistance and abrasion resistance, etc. The high-performance triple eccentric bi-directional hard seal butterfly valve is a new type of butterfly valve. The high-performance triple eccentric bidirectional hard seal butterfly valve adopts a brand new design concept, with its valve body and seat as one-piece components, and the sealing surface layer of the seat surfacing welded with temperature- and corrosion-resistant alloy materials, which greatly enhances the valve’s high-temperature and corrosion-resistant performance.

In addition, the butterfly valve also adopts the design of multi-layer soft stacked seals fixed on the valve plate, which makes the butterfly valve lighter in operation, no friction in opening and closing, and with the increasing torque of the transmission mechanism to compensate for the sealing, thus improving the sealing performance of the butterfly valve and prolonging its service life. However, this design also has some problems, such as the medium on the sealing surface of the positive scouring will affect the sealing performance, as well as structural constraints lead to not applicable to small diameter valves and so on.

In order to solve these problems, the high-performance triple eccentric bi-directional hard seal butterfly valve has been further innovated. The seat seal consists of a soft T-shaped sealing ring on both sides of the multi-layer stainless steel sheet, this design has both the ruggedness and durability of the metal hard seal, and the sealing performance of the soft seal. At the same time, the sealing surface of the valve plate and the valve seat is inclined cone structure, this structure makes the valve in the positive medium pressure increases, the valve plate inclined cone surface and the valve seat sealing surface squeeze the tighter, the better the sealing effect.

More advanced is that the butterfly valve is also added with adjusting ring and spring structure, this design effectively compensates for the tolerance band between the sleeve and the valve body and the elastic deformation of the valve stem under the medium pressure, which solves the sealing problem of the valve in the process of bidirectional interchangeable medium transportation. Whether in low or high temperature, the butterfly valve has zero leakage sealing performance.

Tests have proved that, in the forward medium flow, the pressure of the sealing surface is generated by the torque of the transmission device and the joint action of the medium pressure. When the medium flows in the opposite direction, the deformation energy stored in the spring of the adjusting ring after being loaded can compensate for the tight pressure of the sealing surface of the valve plate and the valve seat, and play the role of automatic compensation. Therefore, this kind of butterfly valve does not need to install soft and hard multi-layer sealing rings on the valve plate, but is directly installed on the valve body, which is more simple and efficient.

To summarize, high-performance three eccentric bidirectional hard seal butterfly valve is gradually replacing the traditional gate valve, globe valve and spherical valve and other types of valves with its excellent performance and wide application prospects. Its appearance not only promotes the innovation and development of butterfly valve technology, but also provides a more reliable and efficient solution for fluid control in the industrial field.